Question: Design specifications require that a key dimension on a product measure 102 10 units. A process being considered for producing this product has a standard

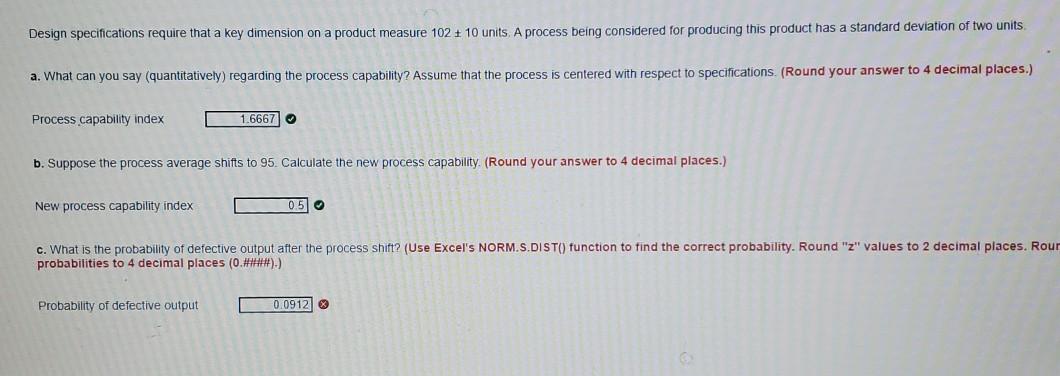

Design specifications require that a key dimension on a product measure 102 10 units. A process being considered for producing this product has a standard deviation of two units a. What can you say (quantitatively) regarding the process capability Assume that the process is centered with respect to specifications. (Round your answer to 4 decimal places.) Process capability index 1.6667 b. Suppose the process average shifts to 95. Calculate the new process capability. (Round your answer to 4 decimal places. New process capability index 0.5 c. What is the probability of defective output after the process shift? (Use Excel's NORM.S.DIST() function to find the correct probability. Round "z" values to 2 decimal places. Rour probabilities to 4 decimal places (0.####).) Probability of defective output 0.0912

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock