Question: desing an LP modelthat saticify the question ( no math calc. needed ) A system for printer manufacturing consists of a number of factories, warehouses,

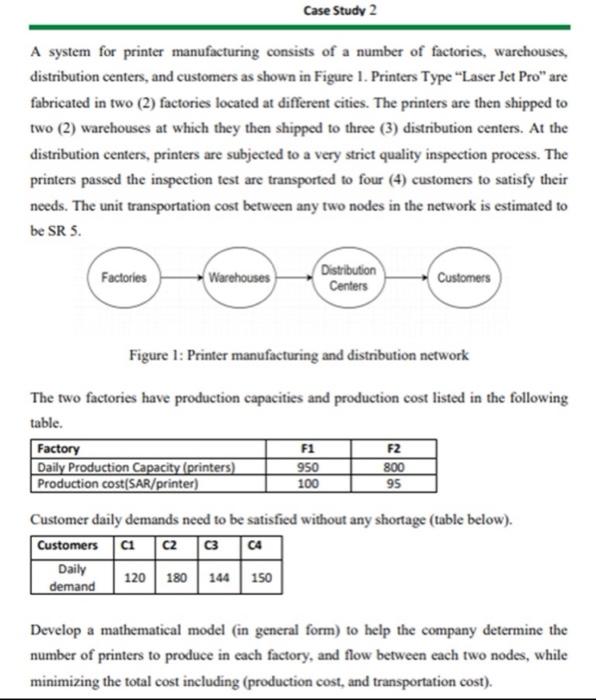

A system for printer manufacturing consists of a number of factories, warehouses, distribution centers, and customers as shown in Figure 1. Printers Type "Laser Jet Pro" are fabricated in two (2) factories located at different cities. The printers are then shipped to two (2) warehouses at which they then shipped to three (3) distribution centers. At the distribution centers, printers are subjected to a very strict quality inspection process. The printers passed the inspection test are transported to four (4) customers to satisfy their needs. The unit transportation cost between any two nodes in the network is estimated to be SR 5. Figure 1: Printer manufacturing and distribution network The two factories have production capacities and production cost listed in the following table. Customer daily demands need to be satisfied without any shortage (table below). Develop a mathematical model (in general form) to help the company determine the number of printers to produce in each factory, and flow between each two nodes, while minimizing the total cost including (production cost, and transportation cost)

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts