Question: Develop a build time model for Fortus 900mc from Stratasys. Note that this is a point-wise vector process using FDM technology without overlapping scans.

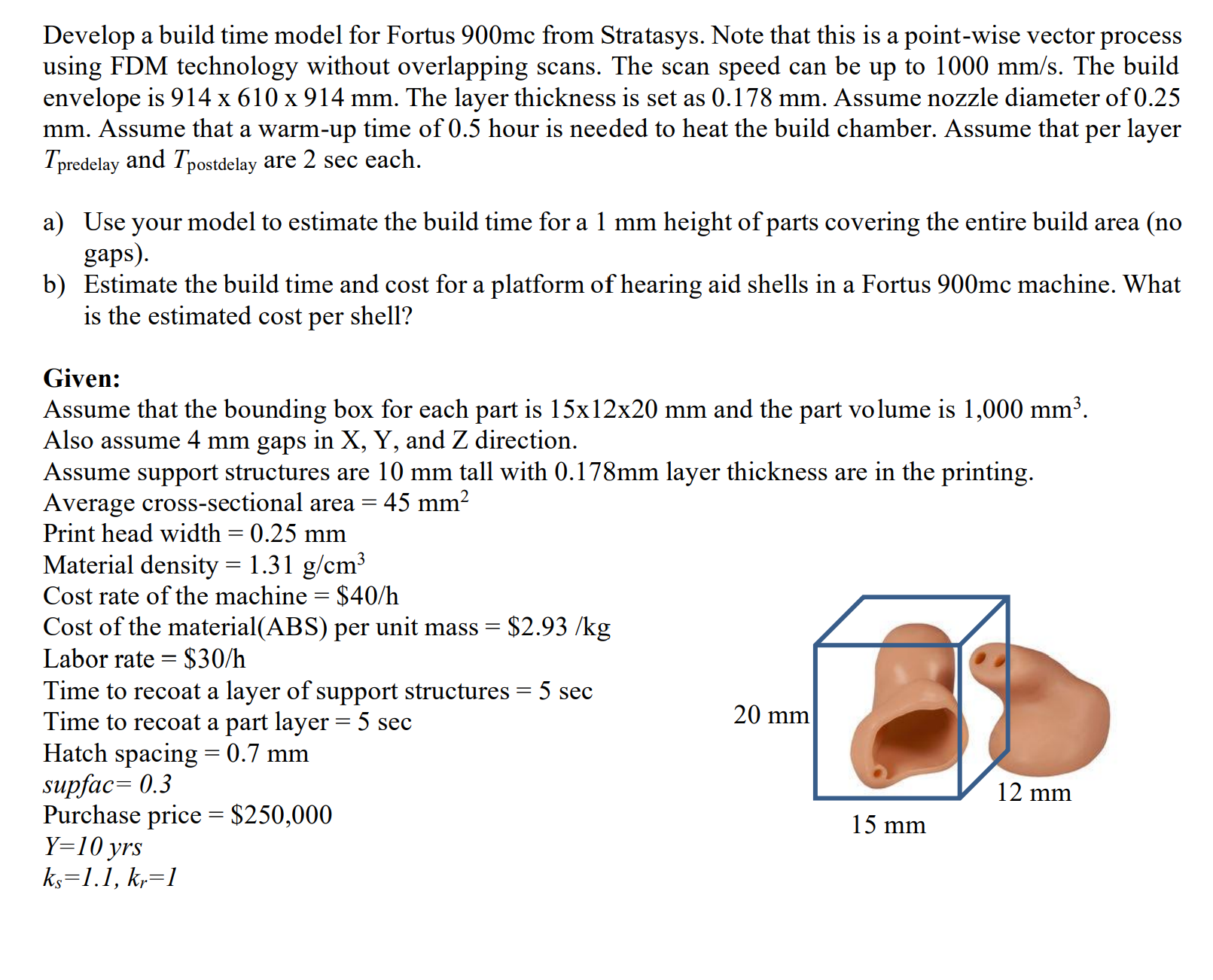

Develop a build time model for Fortus 900mc from Stratasys. Note that this is a point-wise vector process using FDM technology without overlapping scans. The scan speed can be up to 1000 mm/s. The build envelope is 914 x 610 x 914 mm. The layer thickness is set as 0.178 mm. Assume nozzle diameter of 0.25 mm. Assume that a warm-up time of 0.5 hour is needed to heat the build chamber. Assume that per layer Tpredelay and Tpostdelay are 2 sec each. a) Use your model to estimate the build time for a 1 mm height of parts covering the entire build area (no gaps). b) Estimate the build time and cost for a platform of hearing aid shells in a Fortus 900mc machine. What is the estimated cost per shell? Given: Assume that the bounding box for each part is 15x12x20 mm and the part volume is 1,000 mm. Also assume 4 mm gaps in X, Y, and Z direction. Assume support structures are 10 mm tall with 0.178mm layer thickness are in the printing. Average cross-sectional area = 45 mm Print head width = 0.25 mm Material density = 1.31 g/cm Cost rate of the machine = $40/h Cost of the material(ABS) per unit mass Labor rate = $30/h = $2.93/kg 5 sec 20 mm Time to recoat a layer of support structures Time to recoat a part layer = 5 sec Hatch spacing= 0.7 mm supfac=0.3 Purchase price = $250,000 Y=10 yrs ks=1.1, kr=1 12 mm 15 mm

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts