Question: Developing a Control Plan Control PhaseIn this assignment, you are asked to complete a section of the Control Plan Worksheet Download Control Plan Worksheet to

Developing a Control Plan

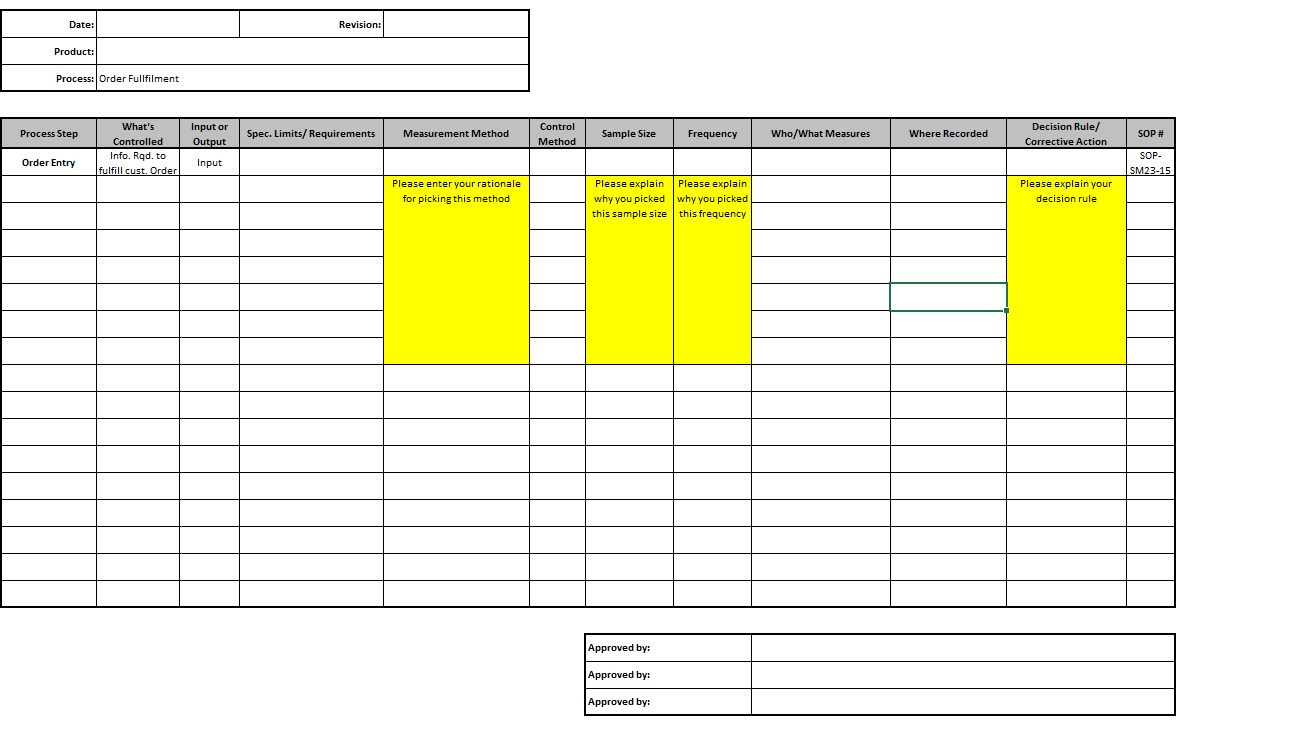

Control PhaseIn this assignment, you are asked to complete a section of the Control Plan Worksheet

Download Control Plan Worksheet to demonstrate your ability to create a control plan for the L&M Deliveries Project.

Download the Control Plan Worksheet file. There are two tabs The first, Details, describes how to fill in each section of the Control Plan. The control plan is found on the second tab, Control Plan Master.

A key step in the Order Fulfillment process is entering customer order information. Your assignment is to complete the Control Plan Master for this step. You can make assumptions where needed eg whowhat measures but please provide your rationale for your decisions for the Measurement Method, Sample Size, Frequency, and Decision RuleCorrective Action in the yellow highlighted cells below this criteria.

Participation in this assignment is required for the successful completion of the course.

Late and Missed Deliveries Reduction Project

Throughout the course, you will refer to the L&M Deliveries case presented below to complete your assignments. Each assignment will build on the previous and take you through various parts of what a real project would include and require of a Green Belt team member.

Assume you work in logistics for a parts manufacturer and you have been assigned as the team leader for an LSSGB project focused on reducing the number of missed and late deliveries to your customers assembly plants. You were assigned this project by your Sponsor, Susan Keyes, the VP of Operations, and will be supported by your organizations LSSBB Dan Burton, who will serve as your coach.

Susan directed this project to be activated because the number of late and missed deliveries has been steadily increasing over the past year. Historically, the company had maintained an average ontime monthly delivery performance, but over the past months, it has steadily deteriorated to an average of reaching a low of last month.

The impact has been dramatic: your premium freight costs have increased by $ from last year, you lost two customers with average annual revenue of $M and you were forced to reimburse one customer $ for an assembly line shutdown caused by one of your late deliveries.

Susan and Dan have indicated you can have up to six parttime team members to support the effort; you just need to tell them what functions you need. Youll have a maximum of six months to complete the project, but less time is better.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock