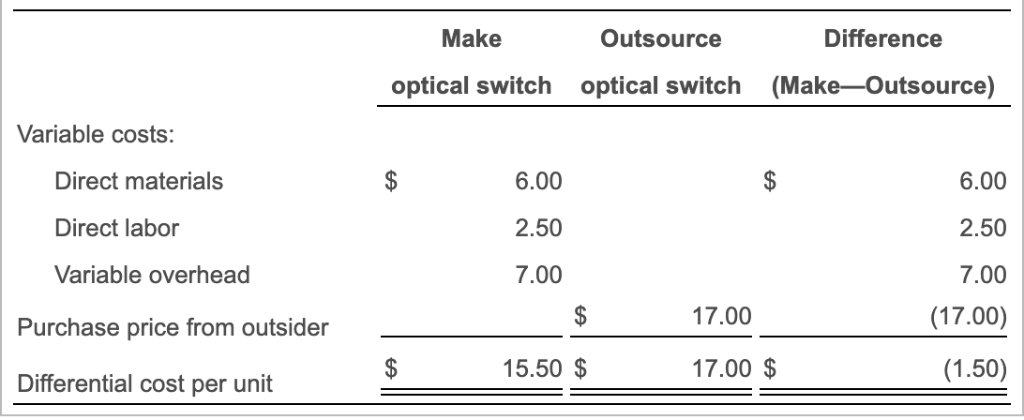

Question: Difference Make Outsource optical switch optical switch (Make-Outsource) Variable costs: Direct materials 6.00 6.00 Direct labor 2.50 2.50 7.00 Variable overhead 7.00 17.00 (17.00) Purchase

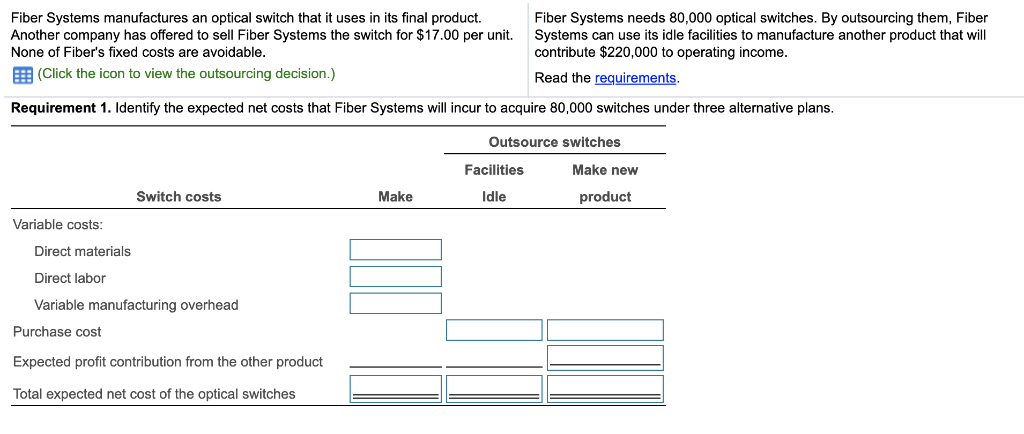

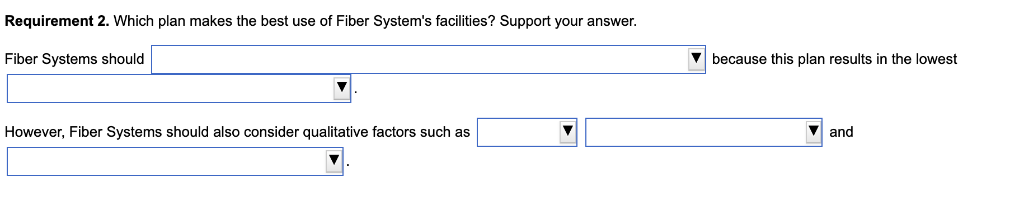

Difference Make Outsource optical switch optical switch (Make-Outsource) Variable costs: Direct materials 6.00 6.00 Direct labor 2.50 2.50 7.00 Variable overhead 7.00 17.00 (17.00) Purchase price from outsider 17.00 $ 15.50 $ $ (1.50) Differential cost per unit CA Fiber Systems manufactures an optical switch that it uses in its final product. Another company has offered to sell Fiber Systems the switch for $17.00 per unit None of Fiber's fixed costs are avoidable. Fiber Systems needs 80,000 optical switches. By outsourcing them, Fiber Systems can use its idle facilities to manufacture another product that will contribute $220,000 to operating income. E(Click the icon to view the outsourcing decision.) Read the requirements. Requirement 1. Identify the expected net costs that Fiber Systems will incur to acquire 80,000 switches under three alternative plans. Outsource switches Facilities Make new Switch costs Make Idle product Variable costs Direct materials Direct labor Variable manufacturing overhead Purchase cost Expected profit contribution from the other product Total expected net cost of the optical switches Requirement 2. Which plan makes the best use of Fiber System's facilities? Support your answer. Fiber Systems should because this plan results in the lowest and However, Fiber Systems should also consider qualitative factors such as

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts