Question: Discuss how Time-Based logistics (like JeanJeans system) can be processed for order fulfilments from the Woodlands distribution centers to HomeDecor stores b)What are the benefits

Discuss how Time-Based logistics (like JeanJeans system) can be processed for order fulfilments from the Woodlands distribution centers to HomeDecor stores

b)What are the benefits and barriers (short and long-term) to the proposal for both Woodland and HomeDecor? What other factors need to be considered to improve the current proposal for long-run viability?

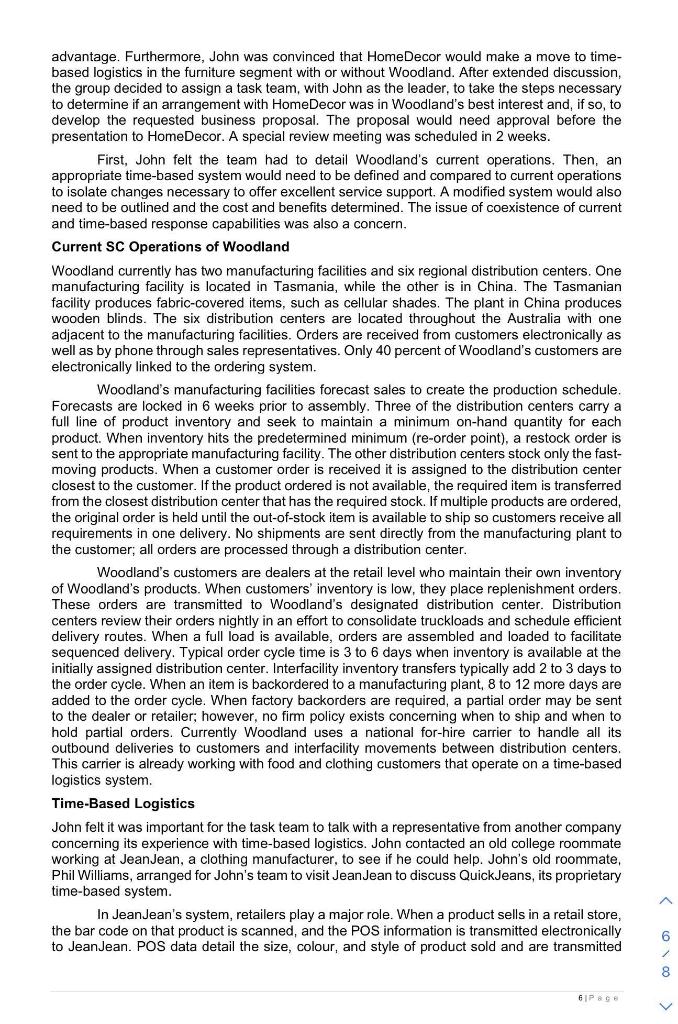

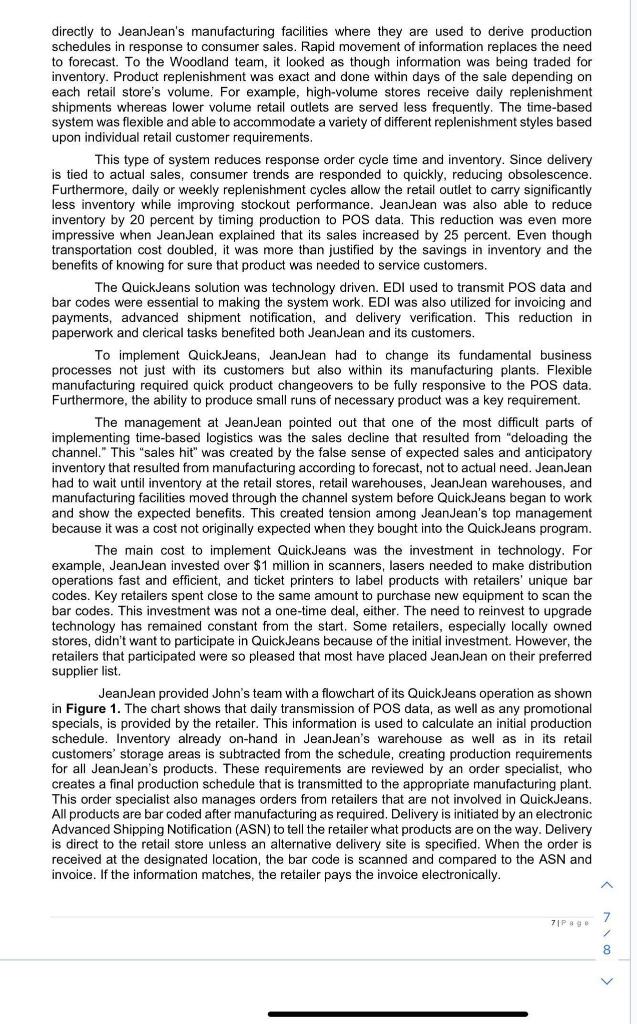

John Smith had just returned from what may prove to be one of his most important sales calls. John, a sales representative for a top window fashion (furnishing) manufacturer Woodland, had been meeting with a representative from Home Decor, a major home decorating retailer. It seems the buyer, Nan Peterson, and the product team she heads had just returned from the annual Council of Logistics Management Conference. At the conference, Nan's team had attended several sessions on time-based logistics strategies. Even though Nan and her team had just been exposed to the new strategies, they felt it had the potential for significant competitive advantage in their industry. At the meeting with John, Nan explained that Home Decor is an entrepreneurial company that encourages product teams to try new products and channel relations. The few rules a team has to follow are simple: (1) deal only with manufacturers (no independent distributors are contacted) and (2) keep costs low and service high. The second rule highlights Home Decor's basic business philosophy, Home Decor is a design and home decorating retail chain that follows the warehouse club retail format. As such, a premium is placed on maintaining low overhead to support an everyday low price (EDLP) strategy. Service is also a premium since Home Decor targets two distinct customer segments: do-it-yourself consumers, who need special in-store guidance; and interior decorators, who need speedy checkouts and convenient delivery or pickup. Nan explained that the team has been considering applying time-based logistics strategies to window fashion products. Such an arrangement had the potential to improve product availability for in-store customers while reducing overall inventory. Home Decor's close relationship with professional decorators required continued attention to improve its profitability and to ensure long-term growth. Interior decorators need convenient and exacting service, and Home Decor feels that time-based logistics applied to window fashions could be an important step to improving profitability to ensure long term growth and improve competitiveness. Home Decor's main concern is that the window fashion industry as a whole appears to be trailing other industries in terms of sophisticated logistics operations and use of technology in supply chain. For example, the window fashions industry has invested little in information technology and maintains high inventories throughout the channel, including at the retail level. The results other firms reported for their innovative logistics applications gave Home Decor a new insight into how an alliance with a window fashion manufacturer might create a best practice distribution system with lower costs and less inventory. Nan told John that Woodland had the potential to achieve an exclusive distribution arrangement with Home Decor if the two companies could create time-based logistical capability. Woodland was chosen since the business press had recently featured articles on its new organisation plan that focused on channels of distribution and leading-edge logistics strategies. In addition, Woodland was beginning to invest in information technology. Nan felt both companies should be able to reduce overall channel costs and offer customers superior product availability. Her specific request was for John to formulate a tentative proposal within three weeks to strike while the iron was hot. Nan knew the timing and unexpected opportunity created a great challenge for Woodland, but she explained that Home Decor strives to remain leading edge. Furthermore, Home Decor wants to increase annual growth to 20 percent and feels that Window fashions offers the best opportunities. As such, top management attention is on this potential business arrangement. John's discussion with his sales manager As John walked to his regional sales manager's office, it was hard to conceal his excitement. The potential agreement Home Decor offered was enormous. However, the effort required to get all groups at Woodland involved would be great. The first step was to convince top management of the unique opportunity so that a team could be formed to create the proposal Home Decor was expecting. 31 Page John's boss, Frank Harrison, was on the phone as John walked in. John carefully planned his words while Frank finished his conversation. As Frank hung up the phone, John blurted out, "We have got the potential for an exclusive with Home Decor, but they want a customized delivery system. The proposal's due in three weeks. I think we need the top brass in on this one. It's big.' John's discussion with his sales manager As John walked to his regional sales manager's office, it was hard to conceal his excitement The potential agreement Home Decor offered was enormous. However, the effort required to get all groups at Woodland involved would be great. The first step was to convince top management of the unique opportunity so that a team could be formed to create the proposal Home Decor was expecting. 31P John's boss, Frank Harrison, was on the phone as John walked in. John carefully planned his words while Frank finished his conversation. As Frank hung up the phone, John blurted out, "We have got the potential for an exclusive with Home Decor, but they want a customized delivery system. The proposal's due in three weeks. I think we need the top brass in on this one. It's big." Frank's reply was typical. "It's not April 1 (one) again already, is it John? What's the problem with our current system? Three weeks! It will never happen. After John explained the meeting with Nan, Frank got on the phone to arrange a senior management review. Surprisingly, a business planning meeting was scheduled for the coming Friday, Frank and John could get on the agenda under new business. What a break! It was Wednesday and John began to reorganize his calendar to concentrate on the Friday meeting. The first item John focused on was researching Home Decor. He discovered that Home Decor operated over 60 warehouse-style stores in Australia with the average store being over 80,000 square feet and offering 25,000 different products. Typical sales breakdown is 50 percent wallpaper and draperies, 25 percent accessory pieces, 20 percent lighting and electrical fixtures and 5 percent Window fashion products. The window fashions sold include (1) cellular shades in various designed, plated fabrics; (2) wood blinds in a variety of colours and finishes; (3) fashion verticals made in fabrics or PVC; and (4) standard aluminium mini blinds. Woodland is one of the three manufacturers that currently supplies the first three types of window fashions sold at Home Decor. Home Decor was the industry leader with 10 percent of the $120 billion home decorating retail market. Forecasts indicate that the market will reach $150 billion in five years. Industry observers predict that Home Decor is positioned to enjoy up to 20 percent of total industry sales. Home Decor is also the first major player in its market to offer online ordering, their competitors online/internet pages offer product and store information only. Online sales are estimated to increase to $500 billion by year end. Home Decor is anxious to see how its online services can be expanded to manufacturing partners to reshape the business and ordering processes. Home Decor is dedicated to service. In-store classes illustrate design techniques, repair and installation procedures on wallpaper, drapes, and lighting and electrical fixtures. The classes are taught by Home Decor's employees, most of whom are retired or part-time professional decorators and contractors. Home Decor provides installation service in a majority of its stores as well as professional decorating services. Both services are offered on a fee basis Forty percent of Home Decor's sales involve professional decorators. The remaining 60 percent come from do-it-yourself consumers. The professional segment is quite large, and Home Decor works closely with this group to meet service requirements. The Propartners also tend to be technically sophisticated and this are using Internet to price competing products as well as compare lead times. Nan would want to involve a group of clients in the Propartner Program in an evaluation of any new strategy. Second, each Home Decor store's inventory is restricted to display items plus a limited stock of fast-moving products. Typically, only 20 percent of all customer orders can be filled from store inventory. This is for two reasons: (i) only standard sizes are held in inventory and (ii) typically only high trend colours and fabrics are held in inventory. As such, if a store does not have a specific piece of furniture, an order for the item is forwarded to a regional warehouse where the item is taken from inventory and sent to the store the following day. If the order is highly customised, then a custom order must be placed with the manufacturer. Window fashions from the regional warehouse are available for delivery or customers can pick up 2 days after the original order, assuming the warehouse has stock. If the regional warehouse is out of stock, the piece is typically not available for shipment or pickup for 5 to 7 days because an interfacility transfer or manufacturer shipment is required. Currently 25 percent of all orders for window fashions are custom orders. The remainder are standard products held in inventar at the store or the regional warehouse. Howyor custom e evnerted to increase a customere select onetandard size 4. 8 V T Currently 25 percent of all orders for window fashions are custom orders. The remainder are standard products held in inventory at the store or the regional warehouse. However, custom orders are expected to increase as customers select non-standard size windows, Propartners also indicated to Home Dcor that the trend is toward more cellular shares and wood blinds rather than standard mini blinds and draperies. Since many Propartners are working on remodeling/redecorating projects, unexpected problems and delays can easily cause schedule changes. On a day-in and day-out basis, the exact time of furniture delivery and installation is difficult to accurately gauge. Propartners would like to be able to place an order 48 hours (or less) before the expected completion to reduce cost of rescheduling. Working on shorter timetables would improve their efficiency and cash flow and is perceived by Propartners as a major benefit. Currently, Propartners buy mostly from independent distributors who have more flexible delivery programs. Friday's meeting was long. Frank and John weren't scheduled to present until near the end and they hoped it wouldn't run overtime, forcing them to be rescheduled. Finally, it was their turn. Frank started the presentation and discussed how long and hard a struggle it had been to develop a relationship with Home Decor. Then John spoke of the benefits. He built on the need to develop new business relationships because Woodland was involved in an alliance with a retailer in financial trouble. This retailer, Home & Living, had historically accounted for 25 percent of Woodland's sales, but this figure was dropping dramatically. Home & Living's erratic purchases were creating under-capacity in Woodland's manufacturing facilities. Furthermore, Home Decor had a relationship with decorators, a customer group that Woodland had been targeting under its reorganization plan. Woodland's image was as a value leader good quality Window fashions at a low price. Attracting professional decorators to its products would definitely enhance Woodland's image. Furthermore, Woodland hoped to have some direct contact with professional decorators to get firsthand information on upcoming fashion trends. Finally, an exclusive arrangement with Home Decor appeared critical for the future, Window fashions manufacturing is heavily consolidated among a few key players, meaning stiff competition. While the home decorating industry remains heavily fragmented, Home Decor is a leader and appears positioned to grow faster than competitors. Even though Home Decor currently only has 10 percent of the market share, they have unlimited growth potential and are often referred to as the Walmart of the home decorating industry. Reaction from senior management was mixed. While many were excited about the potential, they were also cautious. The long-term relationship with Home & Living that had prospered for 50 years was clearly becoming a potential problem for Woodland. Relying on Home & Living had created a false sense of security, and when Home & Living suffered financially during the recessions, Woodland also suffered. Furthermore, Home & Living's reputation as a quality retailer was beginning to decline. In fact, it was getting the reputation for providing low-quality, outdated products. Top management was afraid to launch another close relationship that tied Woodland's success to another company. Frank responded that Home Decor had achieved at least 10 percent growth each year for the last 15 years, even though the recessions. The main reason for this growth was its advertising strategy, which convinced consumers who couldn't afford a new home that they could afford to remodeVredesign their current one. Another concem was the shift in traditional operations necessary to support a customized delivery system. While no concrete evidence was available on the exact requirements of customized delivery, it was still apparent that the service being requested was unique and non-traditional and might require major reorganization and financial investment. Also, several board members wondered how traditional customers, not interested in time- based logistics, would benefit. Their specific concern was that the commitment to Home Decor would increase the overall cost of with all custome In short, som custome would be over serviced at a cost penalty. There was also concern that Woodland's current system could not provide the service Home Decor required. John agreed these were serious concerns, but reminded the group of the potential benefits that could result from a successful shift to time-based logistics. Not only was the exclusive agreement with Home Decor important, but this "test case" with a major retailer could forge a leading-edge path for Woodland, resulting in difficult-to-duplicate competitive 5 8 SIP advantage. Furthermore, John was convinced that Home Decor would make a move to time- based logistics in the furniture segment with or without Woodland. After extended discussion, the group decided to assign a task team, with John as the leader, to take the steps necessary to determine if an arrangement with Home Decor was in Woodland's best interest and, if so, to develop the requested business proposal. The proposal would need approval before the presentation to Home Decor. A special review meeting was scheduled in 2 weeks. First, John felt the team had to detail Woodland's current operations. Then, an appropriate time-based system would need to be defined and compared to current operations to isolate changes necessary to offer excellent service support. A modified system would also need to be outlined and the cost and benefits determined. The issue of coexistence of current and time-based response capabilities was also a concern. Current SC Operations of Woodland Woodland currently has two manufacturing facilities and six regional distribution centers. One manufacturing facility is located in Tasmania, while the other is in China. The Tasmanian facility produces fabric-covered items, such as cellular shades. The plant in China produces wooden blinds. The six distribution centers are located throughout the Australia with one adjacent to the manufacturing facilities. Orders are received from customers electronically as well as by phone through sales representatives. Only 40 percent of Woodland's customers are electronically linked to the ordering system. Woodland's manufacturing facilities forecast sales to create the production schedule. Forecasts are locked in 6 weeks prior to assembly. Three of the distribution centers carry a full line of product inventory and seek to maintain a minimum on-hand quantity for each product. When inventory hits the predetermined minimum (re-order point), a restock order is sent to the appropriate manufacturing facility. The other distribution centers stock only the fast- closest to the customer. If the product ordered is not available, the required item is transferred from the closest distribution center that has the required stock. If multiple products are ordered, the original order is held until the out-of-stock item is available to ship so customers receive all requirements in one delivery. No shipments are sent directly from the manufacturing plant to the customer, all orders are processed through a distribution center. Woodland's customers are dealers at the retail level who maintain their own inventory of Woodland's products. When customers' inventory is low, they place replenishment orders. These orders are transmitted to Woodland's designated distribution center. Distribution centers review their orders nightly in an effort to consolidate truckloads and schedule efficient delivery routes. When a full load is available, orders are assembled and loaded to facilitate sequenced delivery. cycle time is 3 to 6 is available at the initially assigned distribution center. Interfacility inventory transfers typically add 2 to 3 days to the order cycle. When an item is backordered to a manufacturing plant, 8 to 12 more days are to the order cycle. When factory backorders are required, partial order may be sent to the dealer or retailer; however, no firm policy exists concerning when to ship and when to hold partial orders. Currently Woodland uses a national for-hire carrier to handle all its outbound deliveries to customers and interfacility movements between distribution centers. This carrier is already working with food and clothing customers that operate on a time-based logistics system. Typical order 6 days when added to a Time-Based Logistics John felt it was important for the task team to talk with a representative from another company concerning its experience with time-based logistics. John contacted an old college roommate working at JeanJean, a clothing manufacturer, to see if he could help. John's old roommate, Phil Williams, arranged for John's team to visit JeanJean to discuss QuickJeans, its proprietary time-based system. In JeanJean's system, retailers play a major role. When a product sells in a retail store, the bar code on that product is scanned, and the POS information is transmitted electronically to JeanJean. POS data detail the size, colour, and style of product sold and are transmitted 000> ePage directly to JeanJean's manufacturing facilities where they are used to derive production schedules in response to consumer sales. Rapid movement of information replaces the need to forecast. To the Woodland team, it looked as though information was being traded for inventory. Product replenishment was exact and done within days of the sale depending on each retail store's volume. For example, high-volume stores receive daily replenishment shipments whereas lower volume retail outlets are served less frequently. The time-based system was flexible and able to accommodate a variety of different replenishment styles based upon individual retail customer requirements, This type of system reduces response order cycle time and inventory. Since delivery is tied to actual sales, consumer trends are responded to quickly, reducing obsolescence. Furthermore, daily or weekly replenishment cycles allow the retail outlet to carry significantly less inventory while improving stockout performance. JeanJean was also able to reduce inventory by 20 percent by timing production to POS data. This reduction was even more impressive when JeanJean explained that its sales increased by 25 percent. Even though transportation cost doubled, it was more than justified by the savings in inventory and the benefits of knowing for sure that product was needed to service customers. The QuickJeans solution was technology driven. EDI used to transmit POS data and bar codes were essential to making the system work. EDI was also utilized for invoicing and payments, advanced shipment notification, and delivery verification. This reduction in paperwork and clerical tasks benefited both JeanJean and its customers, To implement QuickJeans, JeanJean had to change its fundamental business processes not just with its customers but also within its manufacturing plants. Flexible manufacturing required quick product changeovers to be fully responsive to the POS data. Furthermore, the ability to produce small runs of necessary product was a key requirement. The management at JeanJean pointed out that one of the most difficult parts of implementing time-based logistics was the sales decline that resulted from "deloading the channel." This "sales hit" was created by the false sense of expected sales and anticipatory inventory that resulted from manufacturing according to forecast, not to actual need. JeanJean had to wait until inventory at the retail stores, retail warehouses, JeanJean warehouses, and manufacturing facilities moved through the channel system before QuickJeans began to work and show the expected benefits. This created tension among JeanJean's top management because it was a cost not originally expected when they bought into the QuickJeans program. The main cost to implement QuickJeans was the investment in technology. For example, JeanJean invested over $1 million in scanners, lasers needed to make distribution operations fast and efficient, and ticket printers to label products with retailers' unique bar codes. Key retailers spent close to the same amount to purchase new equipment to scan the bar codes. This investment was not a one-time deal, either. The need reinvest to upgrade technology has remained constant from the start. Some retailers, especially locally owned stores, didn't want to participate in QuickJeans because of the initial investment. However, the retailers that participated were so pleased that most have placed JeanJean on their preferred supplier list. JeanJean provided John's team with a flowchart of its QuickJeans operation as shown in Figure 1. The chart shows that daily transmission of POS data, as well as any promotional specials, is provided by the retailer. This information is used to calculate an initial production schedule. Inventory already on-hand in JeanJean's warehouse as well as in its retail customers' storage areas is subtracted from the schedule, creating production requirements for all JeanJean's products. These requirements are reviewed by an order specialist, who creates a final production schedule that is transmitted to the appropriate manufacturing plant. This order specialist also manages orders from retailers that are not involved in QuickJeans. All products are bar coded after manufacturing as required. Delivery is initiated by an electronic Advanced Shipping Notification (ASN) to tell the retailer what products are on the way. Delivery is direct to the retail store unless an alternative delivery site is specified. When the order received at the designated location, the bar code is scanned and compared to the ASN and invoice. If the information matches, the ailer pays electronically 71 Page 8 Pull Pull JeanJeans Retailers Consumers Daily POS Promotional information Forecast Independent consumption patterns Status Store/Warehouse Inventory HHH Requirements Order overview Order process and delivery ASN Invoice Payment Confirmation Production Figure 1: QuickJeans: A Time-Based Logistics System The Proposal John's team was finally ready to present its time-based delivery system to top management and they hoped the proposal would be accepted. The presentation to Home Decor was scheduled in 3 days. The Woodland task team had worked hard and was confident their proposal had strong selling features for both Woodland and Home Decor. The special meeting with top management was called to order. The task team called the project "Customized Distribution: Creating Time-Based Customer Response" and began discussing how the proposal was developed, including the meeting with JeanJean. The team felt that Woodland could benefit greatly from accepting the Home Decor challenge. Each Home Decor store will transmit POS data on furniture sales at the close of each day. Home Decor will not carry any Woodland inventory in its regional warehouses and will carry only a limited amount of furniture and display items in each store. The POS transmission will include furniture items actually sold from inventory at the store and the furniture ordered, but not in stock. The POS transmission will be sent to a central information service. The information service will sort the POS data and compare them to inventory on hand at each Woodland distribution center. Furniture in stock will be consolidated, while those items that are not in stock will be added to the production schedule and manufactured the next day. After manufacturing, the products will be delivered to the distribution center where initial consolidation of in-stock items will occur, and the entire order will be shipped out to the customer. After shipment, the on-hand quantities at the distribution centers will be examined to determine if a replenishment needs to occur. If the on-hand quantity is too low, a replenishment order will be sent to the appropriate manufacturing. plant

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts