Question: Discussion Case: Alcoas Core Values in Practice Alcoa began under the name of the Pittsburgh Reduction Company in 1888, changing its name to the Aluminum

Discussion Case: Alcoas Core Values in Practice

Alcoa began under the name of the Pittsburgh Reduction Company in 1888, changing its name to the Aluminum Company of America (Alcoa) in 1907. The company was originally founded on a $20,000 investment to capitalize on Charles Martin Halls invention to smelt bauxite ore into the metal known as aluminum. Within a few years, Alcoa had developed into a model of large-scale vertical integration with control over all the inputs to aluminum production. Now, over 125 years later, Alcoa is a global leader in lightweight metals technology, engineering, and manufacturing, with over 60,000 employees and operations in 30 countries.

Since its inception, Alcoa has had a very strong values-based culture. Employees learn early in their career that every decision they make and everything they do must be aligned with the companys values: Integrity; Environment, Health and Safety; Innovation; Respect; and Excellence.

Since the 1990s Alcoas leadership has communicated their commitment to the importance of health and safetyone of the companys core values. Alcoa has a stand-alone environmental health and safety (EHS) organization and a dedicated global ethics and compliance (E&C) organization. The Alcoa E&C program incorporates all of the elements specified in the U.S. Federal Sentencing Guidelines and SarbanesOxley Act. The chief ethics and compliance officer makes regular reports to Alcoas Audit Committee and to the companys Compliance Advisory Council, which includes the CEO, CFO, and chief legal officer. E&C is responsible for global training, the code of conduct, the global anticorruption and trade compliance programs, internal investigations, and the companys global helpline reporting system. The importance of safety, integrity, and doing the right thing is regularly reinforced by management and through E&C communications.

In addition to continuous safety training and education programs, the norm at Alcoa is to start all business meetings with a safety message to identify exits, the evacuation plans in the event of an emergency, and other safety procedures. All locations are required to meet the same overall goal: zero work-related injuries and illnesses. Alcoas management team has made the commitment that no employee should be forced to work in an environment where their safety and the safety of other employees might be jeopardized. Simply stated, no employee should leave work in a worse condition than when they arrived. Through persistent attention over the years, safety at work has become deeply embedded in Alcoas culture and the way we do things around here.

In the late 1990s, activists raised allegations at an Alcoa annual shareholders meeting claiming that health and safety conditions at one of Alcoas Mexican facilities had deteriorated. The individual who spoke at the meeting concluded by saying that the companys behavior in Mexico was inconsistent with its widely publicized values. The company promptly launched an investigation, and Alcoas then CEO personally visited the plant. Although the company learned that many of the issues raised at the annual meeting were unfounded, it also discovered that a few injury incidents and the subsequent actions taken by local managers were not reported to corporate headquarters, as required by company policy. Meetings held with local government officials over safety incidents at the facility were also not reported, even though the results of these meetings indicated Alcoa was in compliance with all appropriate laws and regulations.

Following the review, the company concluded that although the business unit managements response to the safety incidents uncovered in the investigation was adequate, there was a breach of the letter and spirit of our communication practices with respect to major incidents as well as a serious lack of understanding when it came to incident Page 132classification, reporting, and recordkeeping of occupational illnesses. The lack of reporting these safety incidents to others in the company was viewed as unacceptableit meant others in the company were denied the opportunity to learn and possibly prevent similar occurrences at other Alcoa facilities.

A change is leadership was made at the facility, despite the managers stellar record of increased sales and profitability and high marks for quality and customer satisfaction. In an open letter to the entire company, Alcoas then CEO re-emphasized that full compliance with both the letterand spiritof Alcoas policies was imperative, and anything less unacceptable.

Over time, Alcoas focus on safety has paid off. In 2013, Alcoa employees and contractors worldwide worked an entire calendar year fatality-free for the first time in over five decades. The 2014 year-end Alcoa lost workday (LWD) incident rate was 0.10. (This number represents the number of injuries and illnesses resulting in one or more days away from work per 100 full-time workers.) That same year:

42.7% of Alcoas locations worldwide had zero recordable injuries

80.5% of Alcoas locations worldwide had zero lost workdays

These numbers reflect the commitment of not only Alcoa leaders but also the employees, who are empowered to take personal responsibility for ensuring their safety and that of their coworkerseven if that means stopping work when they feel unsafe or unsure.

In 2013, in order to further embed and enhance a values-based culture of integrity and compliance, Alcoa formed a global Integrity Champion Network. This group of high-potential employees was appointed to work within their businesses to raise awareness, promote a Speak-Up culture, and provide advice on various ethics and compliance matters.

In 2014, Alcoa released a new Code of Conduct, providing a road map for Advancing with Integrity. Every employee worldwide received the Code, reinforcing Alcoas values and the shared responsibility for conducting business in accordance with Alcoas highest ethical standards and the law. At the same time, Alcoas 24/7 hotline was rebranded as the Integrity Line. Alcoas ethics and compliance program continues to focus on anticorruption, trade compliance, and adherence with all relevant U.S. and national laws and regulations.

DISCUSSION QUESTIONS:

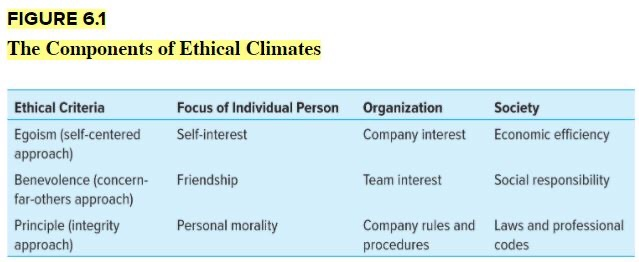

1. How would you classify Alcoas ethical work climate? Which ethical criterion, as shown in Figure 6.1, was used by the company: egoism (self-centered), benevolence (concern for others), or principles (integrity approach)? Or, using Professor Paines two distinct ethics approaches, as discussed in this chapter, was Alcoas approach more compliance or integrity?

2. What role did top management commitment play in developing the ethical work climate and organizational performance seen at Alcoa? What other ethical safeguards are mentioned in the case to support the companys efforts at developing a strong ethical culture?

3. Was Alcoa justified in changing management at the facility for failure to report workplace accidents, even though no serious harm resulted from the workplace incident?

4. Can the focus on safety seen at Alcoa be duplicated into other ethics and compliance areas and how would this be accomplished?

5. Why do you think Alcoas strong values-based culture failed to prevent corrupt acts by a subsidiary, as described earlier in the chapter? Do you think Alcoas creation of a new code of conduct in 2014 will help prevent incidents like this in the future?

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock