Question: Discussion Questions: (see attachment for information) 1. Develop a forecast to use as a basis for sales and Operations Planning. 2. Develop a S&OP plan

Discussion Questions: (see attachment for information)

1. Develop a forecast to use as a basis for sales and Operations Planning.

2. Develop a S&OP plan by month for fiscal year 2015. Consider the use of several different production strategies. Which strategy do you recommend? Use of Excel will greatly save time and make plans.

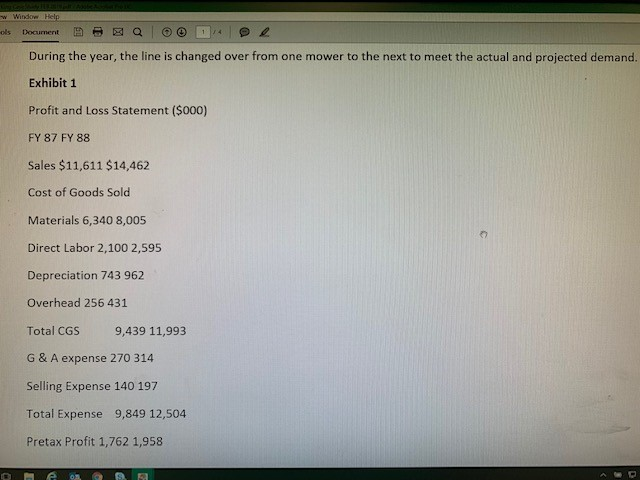

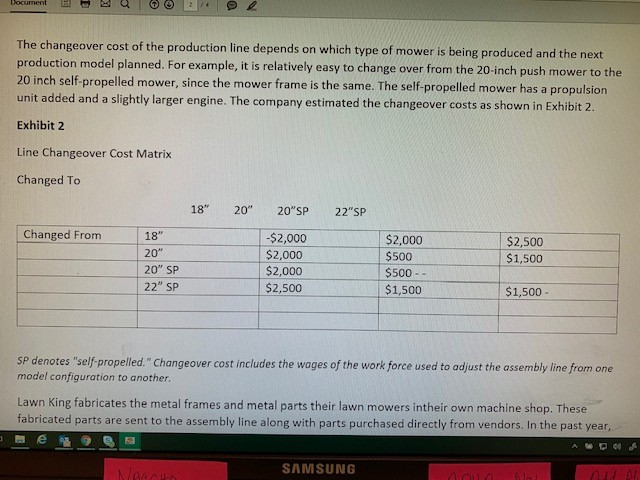

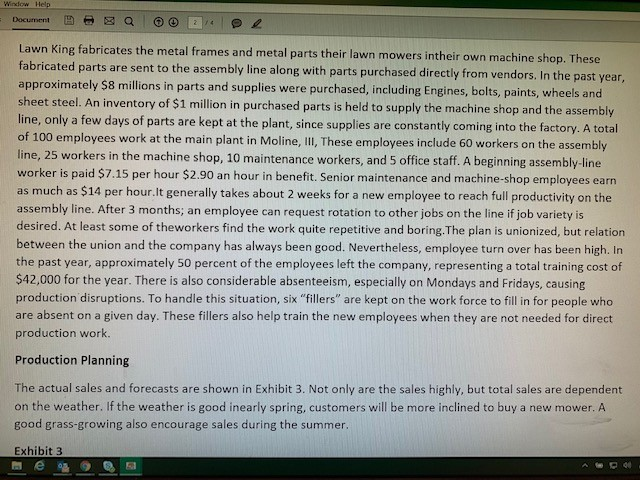

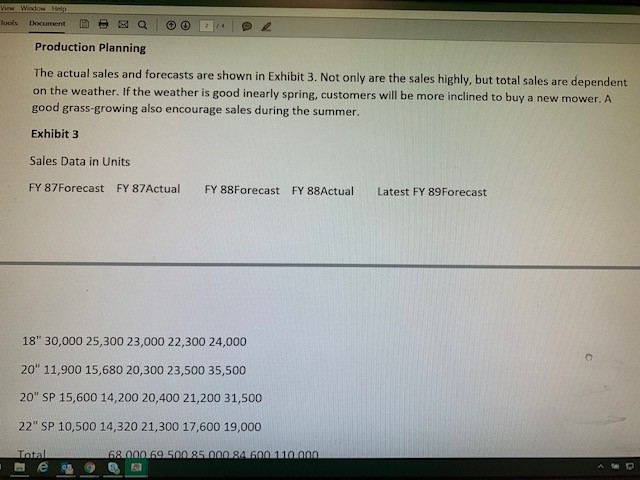

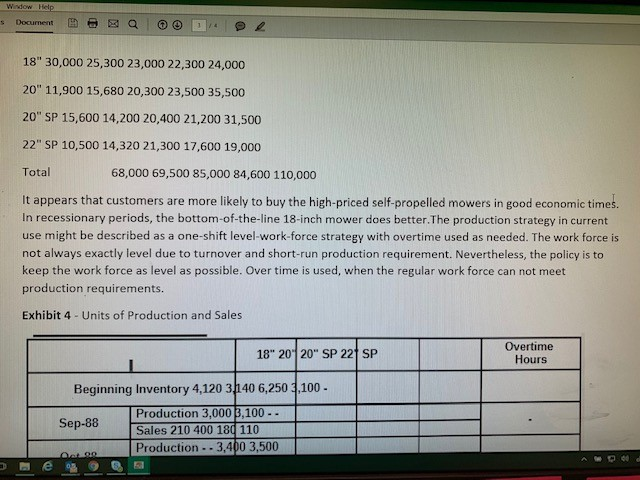

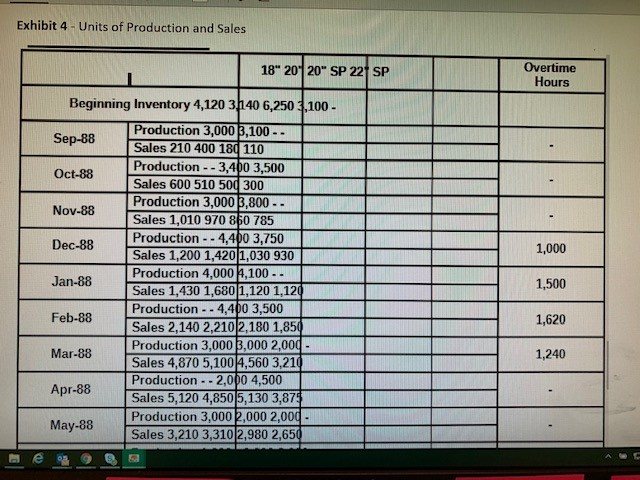

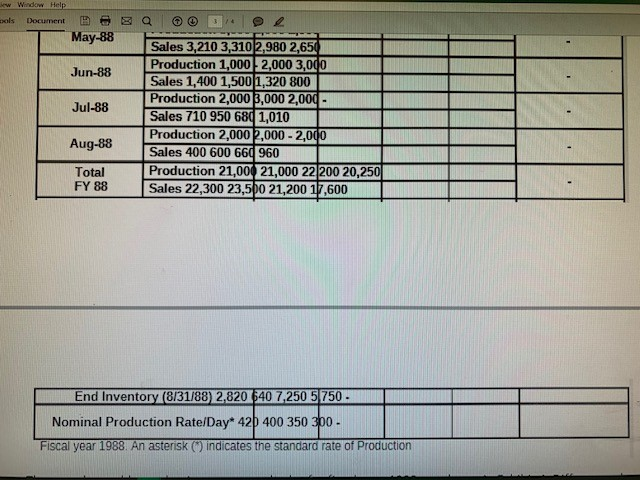

Lawn King, Inc.John Conner, marketing manager for lawn King, looked over the beautiful countryside as he drove in the corporate headquarters in Moline, II. John had asked his Boss, Kathy Wayne, and the General Manager of Lawn King, to call a meeting in order to review the latest forecast figure for fiscal year 1989. When he arrived at the plant, the meeting was ready to begin. Others in attendance at the meeting were James Fairday, plant manager; Joan Watterson, controller; and Harold Pinter, Personal Officer.John started the meeting by reviewing the latest situation. "T've just returnedfrom our annual sales meeting and I think we lost more sales last year than we thought, due to back-order conditions at the factory. We have also reviewed the forecast for next year and feel that sales will be 110,000 units in physical year 1989. The marketing department feels this forecast is realistic and could be exceeded if all goes well."At this point, James Fairday interrupted by saying. "John, you'v got to be kidding. Just three months ago we all sat in this same room and you dedicated sales of 98,000 units for fiscal '89. Now you've raised the forecastby 12 percent. How can we do a responsible job of production planning when we have a moving target to shoot at?"Kathy interjected, "Jim, I appreciate your concern, but we have to be responsive to changing market condition. Here we are in September and we still haven't got the firm plan for fiscal '89, which were just started. I want to use the new forecast and develop an aggregate plan for next year as soon as possible."John added, "We've been taking to our best customers and they're complaining about back orders during the peak selling season. A few have threatened to drop our product line if they don't get better service next year. We have to produce not only enough products but also the right models to service the customer."The Lawn King 1989 fiscal year runs from September 1, 1988 to August 31, 1989.Manufacturing ProcessLawn King is a medium-sized producer of lawn-mower equipment. Last year, sales were $14.5 millions and pretax profits were $2 million, as shown in Exhibit 1. The company makes four lines of lawn mowers, a 20- inch self-propelled mower, and a 22-inch deluxe self-propelled mower. All these mowers are made on the same assembly line During the year, the line is changed over from one mower to the next to meet the actual and projected demand. Exhibit 1 Profit and Loss Statement ($000) FY 87 FY 88 Sales $11,611 $14,462 Cost of Goods Sold Materials 6,340 8,005 Direct Labor 2,100 2,595 Depreciation 743 962 Overhead 256 431 Total CGS 9,439 11,993 G & A expense 270 314 Selling Expense 140 197 Total Expense 9,849 12,504 Pretax Profit 1,762 1,958 The changeover cost of the production line depends on which type of mower is being produced and the next production model planned. For example, it is relatively easy to change over from the 20-inch push mower to the 20 inch self-propelled mower, since the mower frame is the same. The self-propelled mower has a propulsion unit added and a slightly larger engine. The company estimated the changeover costs as shown in Exhibit 2. Exhibit 2 Line Changeover Cost Matrix Changed To 18" 20" 20"SP 22"SP Changed From 18" 20" 20" SP 22" SP $2,000 $2,000 $2,000 $2,500 $2,000 $500 $500 $1,500 $2,500 $1,500 $1,500 SP denotes "self-propelled. "Changeover cost includes the wages of the work force used to adjust the assembly line from one model configuration to another. Lawn King fabricates the metal frames and metal parts their lawn mowers intheir own machine shop. These fabricated parts are sent to the assembly line along with parts purchased directly from vendors. In the past year, SAMSUNG Document ao Lawn King fabricates the metal frames and metal parts their lawn mowers intheir fabricated parts are sent to the assembly line along with parts purchased directly from vendors approximately $8 millions in parts and supplies were purchased, including Engines, bolts, paints, wheels and own machine shop. These . In the past y heet steel. An inventory of $1 million in purchased parts is held to supply the machine shop and the assembly line, only a few days of parts are kept at the plant, since supplies are constantly coming into the factory. A total of 100 em line, 25 workers in the machine shop, 10 maintenance workers, and 5 office staff. A beginning assembly-line worker is paid $7.15 per hour $2.90 an hour in benefit. Senior maintenance and machine-sho as much as $14 per hour.lt generally takes about 2 weeks for a new employee to reach full productivity on the assembly line. After 3 months; an employee can request rotation to other jobs on the line if job variety is desired. At least some of theworkers find the work quite repetitive and boring.The plan is unionized, but relation between the union and the company has always been good. Nevertheless, employee turn over has been high. In the past year, approximately 50 percent of the employees left the company, representing a total training cost of $42,000 for the year. There is also considerable absenteeism, especially on Mondays and Fridays, causing production disruptions. To handle this situation, six "fillers" are kept on the work force to fill in for people who are absent on a given day. These fillers also help train the new employees when they are not needed for direct production work ployees work at the main plant in Moline, IlI, These employees include 60 workers on the assembly Production Planning The actual sales and forecasts are shown in Exhibit 3. Not only are the sales highly, but total sales are dependent on the weather. If the weather is good inearly spring, customers will be more inclined to buy a new mower. A good grass-growing also encourage sales during the summer Exhibit 3 m e w Wndow Help Production Planning The actual sales and forecasts are shown in Exhibit 3. Not only are the sales highly, but total sales are dependent on the weather. If the weather is good inearly spring, customers will be more inclined to buy a new mower. A good grass-growing also encourage sales during the summer Exhibit 3 Sales Data in Units FY 87Forecast FY 87Actual FY 88Forecast FY 88Actual Latest FY 89Forecast 18" 30,000 25,300 23,000 22,300 24,000 20" 11,900 15,680 20,300 23,500 35,500 20" SP 15,600 14,200 20,400 21,200 31,500 22" SP 10,500 14,320 21,300 17,600 19,000 Wndow Help 18" 30,000 25,300 23,000 22,300 24,000 20" 11,900 15,680 20,300 23,500 35,500 20" SP 15,600 14,200 20,400 21,200 31,500 22" SP 10,500 14,320 21,300 17,600 19,000 Total 68,000 69,500 85,000 84,600 110,000 It appears that customers are more likely to buy the high-priced self-propelled mowers in good economic times In recessionary periods, the bottom-of-the-line 18-inch mower does better.The production strategy in current use might be described as a one-shift level-work-force strategy with overtime used as needed. The work force is not always exactly level due to turnover and short-run production requirement. Nevertheless, the policy is to keep the work force as level as possible. Over time is used, when the regular work force can not meet production requirements. Exhibit 4 Units of Production and Sales 18" 201 20" SP 221 SP Overtime Hours Beginning Inventory 4,120 3140 6,250 3,100 Production 3,000B,100 ep-6Sales 210 400 180 110 Production- 3,400 3,500 Exhibit 4- Units of Production and Sales 18" 201 20" SP 221 SP Overtime Hours Beginning Inventory 4,120 3140 6,250 100 Sep-88 Oct-88 Sales 600 510 500300 Nov-88 Production 3,000 3,100.. Sales 210 400 180110 Production-3,400 3,500 Production 3,000B,800 Sales 1,010 970 860 785 Production4,400 3,750 ecSales 1,200 1,4201,030 930 Production 4,000 4,100 Sales 1,430 1,6801,120 1,120 Production4,400 3,500 Sales 2,140 2,2102,180 1,85 Production 3,000 3,000 2,000 Sales 4,870 5,1004,560 3,21 Production-2,000 4,500 Sales 5,120 4,8505,130 3,87 Production 3,0002,000 2,00 Sales 3,210 3,310 2,980 2,65 1,000 1,500 1,620 1,240 Mar-88 May-88 ew Wndow Hel pols Documenta May-88 Jun-88 Jul-88 Sales 3,210 3,310 2,980 2,6 Production 1,000 2,000 3,00 Sales 1,400 1,5001,320 800 Production 2,000 3,0002,000 Sales 710 950 680 1,010 Production 2,0002,000 2,000 Aug-88 Sales 400 600 660 960 Total Production 21,000 21,000 22200 20,250 FY 88 Sales 22,300 23,500 21.200 1 600 entory (8131188)2,820 640 7.2505 Nominal Production Rate/Day* 420 400 350 300 Fiscal year 1988. An asterisk O indicates the standard rate of Production ools Document B a The actual monthly production output and sales for fiscal year 1988 are shown in Exhibit 4. Differences betwe ales and production were absorbedby the inventory. If stock outs occurred, the order was back logged and filledfrom the next available product inventory.Each June, an aggregate production plan is prepared for the upcoming fiscal year. The plan shows the level of production for each model type and month of the year. The aggregate plan is used for personnel planning: inventory planning, and budget preparation. Each month during the year, the plan is revised on the basis of the latest conditions and data.Overtime is paid at 150 percent of regular time.Back to the MeetingThe meeting continued with Joan Peterson saying, "We must find the way toreduce our cost. Last year we carried too much inventory, which required a great deal of capital. At 30 percent carrying cost, we cannot afford to build up as much inventory again next year."Harold Pinter added, "if we reduce our inventories by more nearly chasing demand, the labor force will fluctuate from month to month and our hiring and lay off costs will increase. It currently costs $800 to hire an employee, including the lower productivity on the line during the training period and the effort required to find new employee. I also believe it costs $1500 to layoff and employee including the severance costs and supplemental unemployment benefits that we pay." James Fairday expressed concern that a new shift might have to be added to accommodate the higher forecast. "We are already at plant capacity and the additional units in the new forecast can't be made with one shift. I want to be sure these sales forecast realistic before we go through the trouble of hiring an entire second shift."Lunch time had arrived and the meeting was drawing t a close. Kathy Wayne emphasized that she want a new production planned developed soon. "Jim, I want you to develop an aggregate production plan that considers the costs of ion run. Lawn king utilized a 30 percent carrying cost per year for ventory, over time, hiring, and layoff. If your plant results in back orders, we will have to incur greater costs later in the year to meet demand. I will not allow to same stock out situation that we experienced last year Themeeting adjourned for lunch This cost includes capital costs (20 percentl obsolescence (5 percentl, and warehouse costs (5 percent) employee including the severance costs and supplemental unemployment benefits that we pay." James Fairday expressed concern that a new shift might have to be added to accommodate the higher forecast. "We are already at plant capacity and the additional units in the new forecast can't be made with one shift. I want to be sure these sales forecast realistic before we go through the trouble of hiring an entire second shift."Lunch time had arrived and the meeting was drawing t a close. Kathy Wayne emphasized that she want a new production planned developed soon."Jim, I want you to develop an aggregate production plan that considers the costs of inventory, over time, hiring, and layoff. If your plant results in back orders, we will have to incur greater costs later in the year to meet demand. I will not allow to same stock out situation that we experienced last year. Themeeting adjourned for lunch Discussion Questions: 1. Develop a forecast to use as a basis for sales and Operations Planning 2. Develop a S&OP plan by month for fiscal year 2015. Consider the use of several different production strategies. Which strategy do you recommend? Use of Excel will greatly save time in making these plans. Lawn King, Inc.John Conner, marketing manager for lawn King, looked over the beautiful countryside as he drove in the corporate headquarters in Moline, II. John had asked his Boss, Kathy Wayne, and the General Manager of Lawn King, to call a meeting in order to review the latest forecast figure for fiscal year 1989. When he arrived at the plant, the meeting was ready to begin. Others in attendance at the meeting were James Fairday, plant manager; Joan Watterson, controller; and Harold Pinter, Personal Officer.John started the meeting by reviewing the latest situation. "T've just returnedfrom our annual sales meeting and I think we lost more sales last year than we thought, due to back-order conditions at the factory. We have also reviewed the forecast for next year and feel that sales will be 110,000 units in physical year 1989. The marketing department feels this forecast is realistic and could be exceeded if all goes well."At this point, James Fairday interrupted by saying. "John, you'v got to be kidding. Just three months ago we all sat in this same room and you dedicated sales of 98,000 units for fiscal '89. Now you've raised the forecastby 12 percent. How can we do a responsible job of production planning when we have a moving target to shoot at?"Kathy interjected, "Jim, I appreciate your concern, but we have to be responsive to changing market condition. Here we are in September and we still haven't got the firm plan for fiscal '89, which were just started. I want to use the new forecast and develop an aggregate plan for next year as soon as possible."John added, "We've been taking to our best customers and they're complaining about back orders during the peak selling season. A few have threatened to drop our product line if they don't get better service next year. We have to produce not only enough products but also the right models to service the customer."The Lawn King 1989 fiscal year runs from September 1, 1988 to August 31, 1989.Manufacturing ProcessLawn King is a medium-sized producer of lawn-mower equipment. Last year, sales were $14.5 millions and pretax profits were $2 million, as shown in Exhibit 1. The company makes four lines of lawn mowers, a 20- inch self-propelled mower, and a 22-inch deluxe self-propelled mower. All these mowers are made on the same assembly line During the year, the line is changed over from one mower to the next to meet the actual and projected demand. Exhibit 1 Profit and Loss Statement ($000) FY 87 FY 88 Sales $11,611 $14,462 Cost of Goods Sold Materials 6,340 8,005 Direct Labor 2,100 2,595 Depreciation 743 962 Overhead 256 431 Total CGS 9,439 11,993 G & A expense 270 314 Selling Expense 140 197 Total Expense 9,849 12,504 Pretax Profit 1,762 1,958 The changeover cost of the production line depends on which type of mower is being produced and the next production model planned. For example, it is relatively easy to change over from the 20-inch push mower to the 20 inch self-propelled mower, since the mower frame is the same. The self-propelled mower has a propulsion unit added and a slightly larger engine. The company estimated the changeover costs as shown in Exhibit 2. Exhibit 2 Line Changeover Cost Matrix Changed To 18" 20" 20"SP 22"SP Changed From 18" 20" 20" SP 22" SP $2,000 $2,000 $2,000 $2,500 $2,000 $500 $500 $1,500 $2,500 $1,500 $1,500 SP denotes "self-propelled. "Changeover cost includes the wages of the work force used to adjust the assembly line from one model configuration to another. Lawn King fabricates the metal frames and metal parts their lawn mowers intheir own machine shop. These fabricated parts are sent to the assembly line along with parts purchased directly from vendors. In the past year, SAMSUNG Document ao Lawn King fabricates the metal frames and metal parts their lawn mowers intheir fabricated parts are sent to the assembly line along with parts purchased directly from vendors approximately $8 millions in parts and supplies were purchased, including Engines, bolts, paints, wheels and own machine shop. These . In the past y heet steel. An inventory of $1 million in purchased parts is held to supply the machine shop and the assembly line, only a few days of parts are kept at the plant, since supplies are constantly coming into the factory. A total of 100 em line, 25 workers in the machine shop, 10 maintenance workers, and 5 office staff. A beginning assembly-line worker is paid $7.15 per hour $2.90 an hour in benefit. Senior maintenance and machine-sho as much as $14 per hour.lt generally takes about 2 weeks for a new employee to reach full productivity on the assembly line. After 3 months; an employee can request rotation to other jobs on the line if job variety is desired. At least some of theworkers find the work quite repetitive and boring.The plan is unionized, but relation between the union and the company has always been good. Nevertheless, employee turn over has been high. In the past year, approximately 50 percent of the employees left the company, representing a total training cost of $42,000 for the year. There is also considerable absenteeism, especially on Mondays and Fridays, causing production disruptions. To handle this situation, six "fillers" are kept on the work force to fill in for people who are absent on a given day. These fillers also help train the new employees when they are not needed for direct production work ployees work at the main plant in Moline, IlI, These employees include 60 workers on the assembly Production Planning The actual sales and forecasts are shown in Exhibit 3. Not only are the sales highly, but total sales are dependent on the weather. If the weather is good inearly spring, customers will be more inclined to buy a new mower. A good grass-growing also encourage sales during the summer Exhibit 3 m e w Wndow Help Production Planning The actual sales and forecasts are shown in Exhibit 3. Not only are the sales highly, but total sales are dependent on the weather. If the weather is good inearly spring, customers will be more inclined to buy a new mower. A good grass-growing also encourage sales during the summer Exhibit 3 Sales Data in Units FY 87Forecast FY 87Actual FY 88Forecast FY 88Actual Latest FY 89Forecast 18" 30,000 25,300 23,000 22,300 24,000 20" 11,900 15,680 20,300 23,500 35,500 20" SP 15,600 14,200 20,400 21,200 31,500 22" SP 10,500 14,320 21,300 17,600 19,000 Wndow Help 18" 30,000 25,300 23,000 22,300 24,000 20" 11,900 15,680 20,300 23,500 35,500 20" SP 15,600 14,200 20,400 21,200 31,500 22" SP 10,500 14,320 21,300 17,600 19,000 Total 68,000 69,500 85,000 84,600 110,000 It appears that customers are more likely to buy the high-priced self-propelled mowers in good economic times In recessionary periods, the bottom-of-the-line 18-inch mower does better.The production strategy in current use might be described as a one-shift level-work-force strategy with overtime used as needed. The work force is not always exactly level due to turnover and short-run production requirement. Nevertheless, the policy is to keep the work force as level as possible. Over time is used, when the regular work force can not meet production requirements. Exhibit 4 Units of Production and Sales 18" 201 20" SP 221 SP Overtime Hours Beginning Inventory 4,120 3140 6,250 3,100 Production 3,000B,100 ep-6Sales 210 400 180 110 Production- 3,400 3,500 Exhibit 4- Units of Production and Sales 18" 201 20" SP 221 SP Overtime Hours Beginning Inventory 4,120 3140 6,250 100 Sep-88 Oct-88 Sales 600 510 500300 Nov-88 Production 3,000 3,100.. Sales 210 400 180110 Production-3,400 3,500 Production 3,000B,800 Sales 1,010 970 860 785 Production4,400 3,750 ecSales 1,200 1,4201,030 930 Production 4,000 4,100 Sales 1,430 1,6801,120 1,120 Production4,400 3,500 Sales 2,140 2,2102,180 1,85 Production 3,000 3,000 2,000 Sales 4,870 5,1004,560 3,21 Production-2,000 4,500 Sales 5,120 4,8505,130 3,87 Production 3,0002,000 2,00 Sales 3,210 3,310 2,980 2,65 1,000 1,500 1,620 1,240 Mar-88 May-88 ew Wndow Hel pols Documenta May-88 Jun-88 Jul-88 Sales 3,210 3,310 2,980 2,6 Production 1,000 2,000 3,00 Sales 1,400 1,5001,320 800 Production 2,000 3,0002,000 Sales 710 950 680 1,010 Production 2,0002,000 2,000 Aug-88 Sales 400 600 660 960 Total Production 21,000 21,000 22200 20,250 FY 88 Sales 22,300 23,500 21.200 1 600 entory (8131188)2,820 640 7.2505 Nominal Production Rate/Day* 420 400 350 300 Fiscal year 1988. An asterisk O indicates the standard rate of Production ools Document B a The actual monthly production output and sales for fiscal year 1988 are shown in Exhibit 4. Differences betwe ales and production were absorbedby the inventory. If stock outs occurred, the order was back logged and filledfrom the next available product inventory.Each June, an aggregate production plan is prepared for the upcoming fiscal year. The plan shows the level of production for each model type and month of the year. The aggregate plan is used for personnel planning: inventory planning, and budget preparation. Each month during the year, the plan is revised on the basis of the latest conditions and data.Overtime is paid at 150 percent of regular time.Back to the MeetingThe meeting continued with Joan Peterson saying, "We must find the way toreduce our cost. Last year we carried too much inventory, which required a great deal of capital. At 30 percent carrying cost, we cannot afford to build up as much inventory again next year."Harold Pinter added, "if we reduce our inventories by more nearly chasing demand, the labor force will fluctuate from month to month and our hiring and lay off costs will increase. It currently costs $800 to hire an employee, including the lower productivity on the line during the training period and the effort required to find new employee. I also believe it costs $1500 to layoff and employee including the severance costs and supplemental unemployment benefits that we pay." James Fairday expressed concern that a new shift might have to be added to accommodate the higher forecast. "We are already at plant capacity and the additional units in the new forecast can't be made with one shift. I want to be sure these sales forecast realistic before we go through the trouble of hiring an entire second shift."Lunch time had arrived and the meeting was drawing t a close. Kathy Wayne emphasized that she want a new production planned developed soon. "Jim, I want you to develop an aggregate production plan that considers the costs of ion run. Lawn king utilized a 30 percent carrying cost per year for ventory, over time, hiring, and layoff. If your plant results in back orders, we will have to incur greater costs later in the year to meet demand. I will not allow to same stock out situation that we experienced last year Themeeting adjourned for lunch This cost includes capital costs (20 percentl obsolescence (5 percentl, and warehouse costs (5 percent) employee including the severance costs and supplemental unemployment benefits that we pay." James Fairday expressed concern that a new shift might have to be added to accommodate the higher forecast. "We are already at plant capacity and the additional units in the new forecast can't be made with one shift. I want to be sure these sales forecast realistic before we go through the trouble of hiring an entire second shift."Lunch time had arrived and the meeting was drawing t a close. Kathy Wayne emphasized that she want a new production planned developed soon."Jim, I want you to develop an aggregate production plan that considers the costs of inventory, over time, hiring, and layoff. If your plant results in back orders, we will have to incur greater costs later in the year to meet demand. I will not allow to same stock out situation that we experienced last year. Themeeting adjourned for lunch Discussion Questions: 1. Develop a forecast to use as a basis for sales and Operations Planning 2. Develop a S&OP plan by month for fiscal year 2015. Consider the use of several different production strategies. Which strategy do you recommend? Use of Excel will greatly save time in making these plans

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts