Question: do in excel and explain each step. what formulas are used. 19. Using Figure 2.15, develop a bill of materials for an 8-in aluminum frying

do in excel and explain each step. what formulas are used.

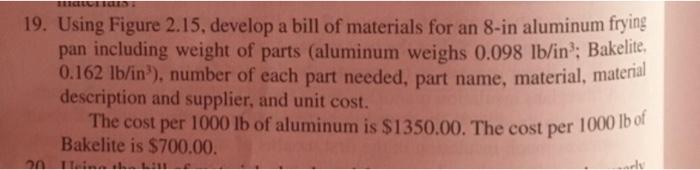

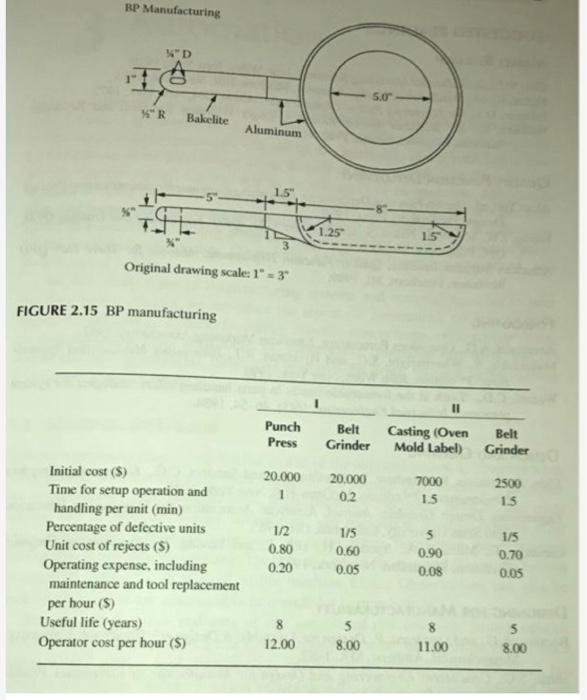

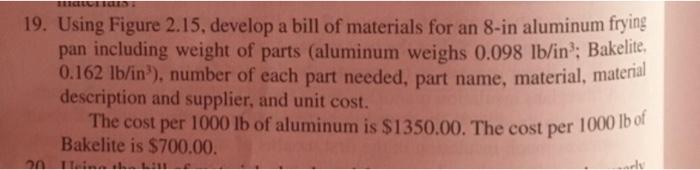

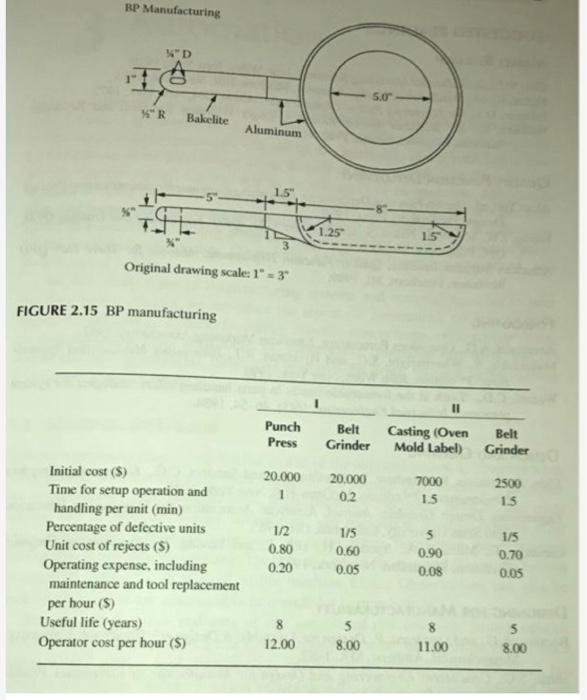

19. Using Figure 2.15, develop a bill of materials for an 8-in aluminum frying pan including weight of parts (aluminum weighs 0.098 lb/in"; Bakelite, 0.162 1b/in), number of each part needed, part name, material, material description and supplier, and unit cost. The cost per 1000 lb of aluminum is $1350.00. The cost per 1000 lb of Bakelite is $700.00. BP Manufacturing WD 5.0 "R Bakelite Aluminum 1.25 1.5 Original drawing scale: 1" - 3 FIGURE 2.15 BP manufacturing II Punch Press Belt Grinder Casting (Oven Mold Label) Belt Grinder 20.000 1 20.000 0.2 7000 1.5 2500 1.5 Initial cost (5) Time for setup operation and handling per unit (min) Percentage of defective units Unit cost of rejects (5) Operating expense, including maintenance and tool replacement per hour (5) Useful life (years) Operator cost per hour ($) 1/2 0.80 0.20 1/5 0.60 0.05 0.90 0.08 1/5 0.70 0.05 8 12.00 5 8.00 8 11.00 5 8.00

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock