Question: Do NOT use linear programming because another service did that for some reason. USE APA formatting Refinery Business Overview A refinery is basically a factory.

Do NOT use linear programming because another service did that for some reason.

USE APA formatting

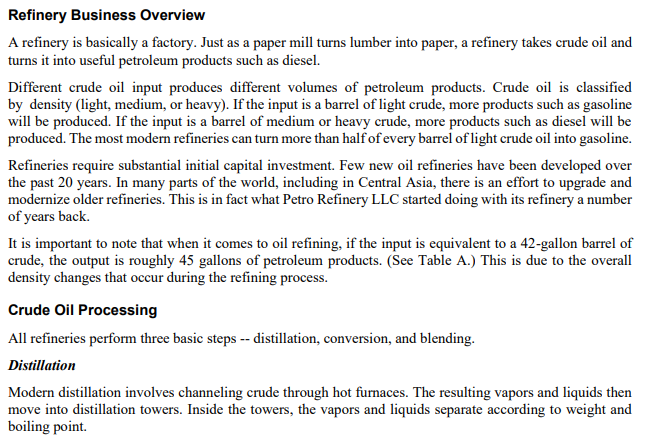

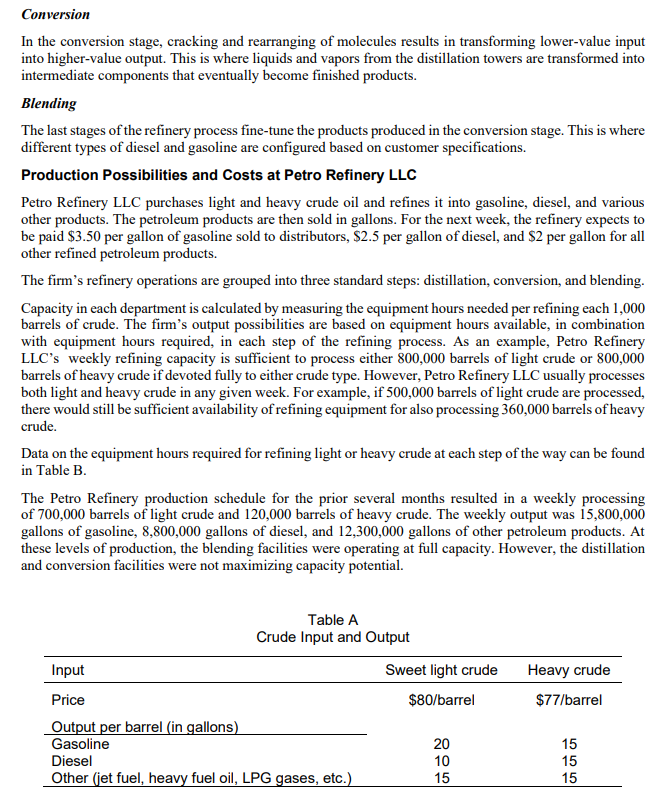

Refinery Business Overview A refinery is basically a factory. Just as a paper mill turns lumber into paper, a refinery takes crude oil and turns it into useful petroleum products such as diesel. Different crude oil input produces different volumes of petroleum products. Crude oil is classified by density (light, medium, or heavy). If the input is a barrel of light crude, more products such as gasoline will be produced. If the input is a barrel of medium or heavy crude, more products such as diesel will be produced. The most modern refineries can turn more than half of every barrel of light crude oil into gasoline. Refineries require substantial initial capital investment. Few new oil refineries have been developed over the past 20 years. In many parts of the world, including in Central Asia, there is an effort to upgrade and modernize older refineries. This is in fact what Petro Refinery LLC started doing with its refinery a number of years back. It is important to note that when it comes to oil refining, if the input is equivalent to a 42-gallon barrel of crude, the output is roughly 45 gallons of petroleum products. (See Table A.) This is due to the overall density changes that occur during the refining process. Crude Oil Processing All refineries perform three basic steps -- distillation, conversion, and blending. Distillation Modern distillation involves channeling crude through hot furnaces. The resulting vapors and liquids then move into distillation towers. Inside the towers, the vapors and liquids separate according to weight and boiling point. Conversion In the conversion stage, cracking and rearranging of molecules results in transforming lower-value input into higher-value output. This is where liquids and vapors from the distillation towers are transformed into intermediate components that eventually become finished products. Blending The last stages of the refinery process fine-tune the products produced in the conversion stage. This is where different types of diesel and gasoline are configured based on customer specifications. Production Possibilities and Costs at Petro Refinery LLC Petro Refinery LLC purchases light and heavy crude oil and refines it into gasoline, diesel, and various other products. The petroleum products are then sold in gallons. For the next week, the refinery expects to be paid $3.50 per gallon of gasoline sold to distributors, $2.5 per gallon of diesel, and $2 per gallon for all other refined petroleum products. The firm's refinery operations are grouped into three standard steps: distillation, conversion, and blending. Capacity in each department is calculated by measuring the equipment hours needed per refining each 1,000 barrels of crude. The firm's output possibilities are based on equipment hours available, in combination with equipment hours required, in each step of the refining process. As an example, Petro Refinery LLC's weekly refining capacity is sufficient to process either 800,000 barrels of light crude or 800,000 barrels of heavy crude if devoted fully to either crude type. However, Petro Refinery LLC usually processes both light and heavy crude in any given week. For example, if 500,000 barrels of light crude are processed, there would still be sufficient availability of refining equipment for also processing 360,000 barrels of heavy crude. Data on the equipment hours required for refining light or heavy crude at each step of the way can be found in Table B. The Petro Refinery production schedule for the prior several months resulted in a weekly processing of 700,000 barrels of light crude and 120,000 barrels of heavy crude. The weekly output was 15,800,000 gallons of gasoline, 8,800,000 gallons of diesel, and 12,300,000 gallons of other petroleum products. At these levels of production, the blending facilities were operating at full capacity. However, the distillation and conversion facilities were not maximizing capacity potential. Table A Crude Input and Output Input Sweet light crude Price $80/barrel Output per barrel (in gallons) Gasoline 20 Diesel 10 Other (jet fuel, heavy fuel oil, LPG gases, etc.) 15 Heavy crude $77/barrel 15 15 15 Input Distillation Conversion Blending Table B Refining equipment demand per 1,000 barrels Sweet light crude Heavy crude Equipment hour available per week 2 hours 2 hours 3,000 2 hours 3 hours 2,400 3 hours 2.5 hours 2,400 Table C Overhead and labor costs Distillation Conversion Blending Fixed overhead $2,000,000/week 3,000,000/week 2,000,000/week Variable overhead $2/barrel 3/barrel 2.5/barrel Labor $0.5/barrel 1/barrel 1/barrel ASSIGNMENT QUESTIONS 1. How much money has Petro Refinery LLC been making per week under its current production policy of processing 700,000 barrels of light and 120,000 barrels of heavy crude after subtracting the labor costs, the variable overhead costs, and the weekly fixed overhead costsStep by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts