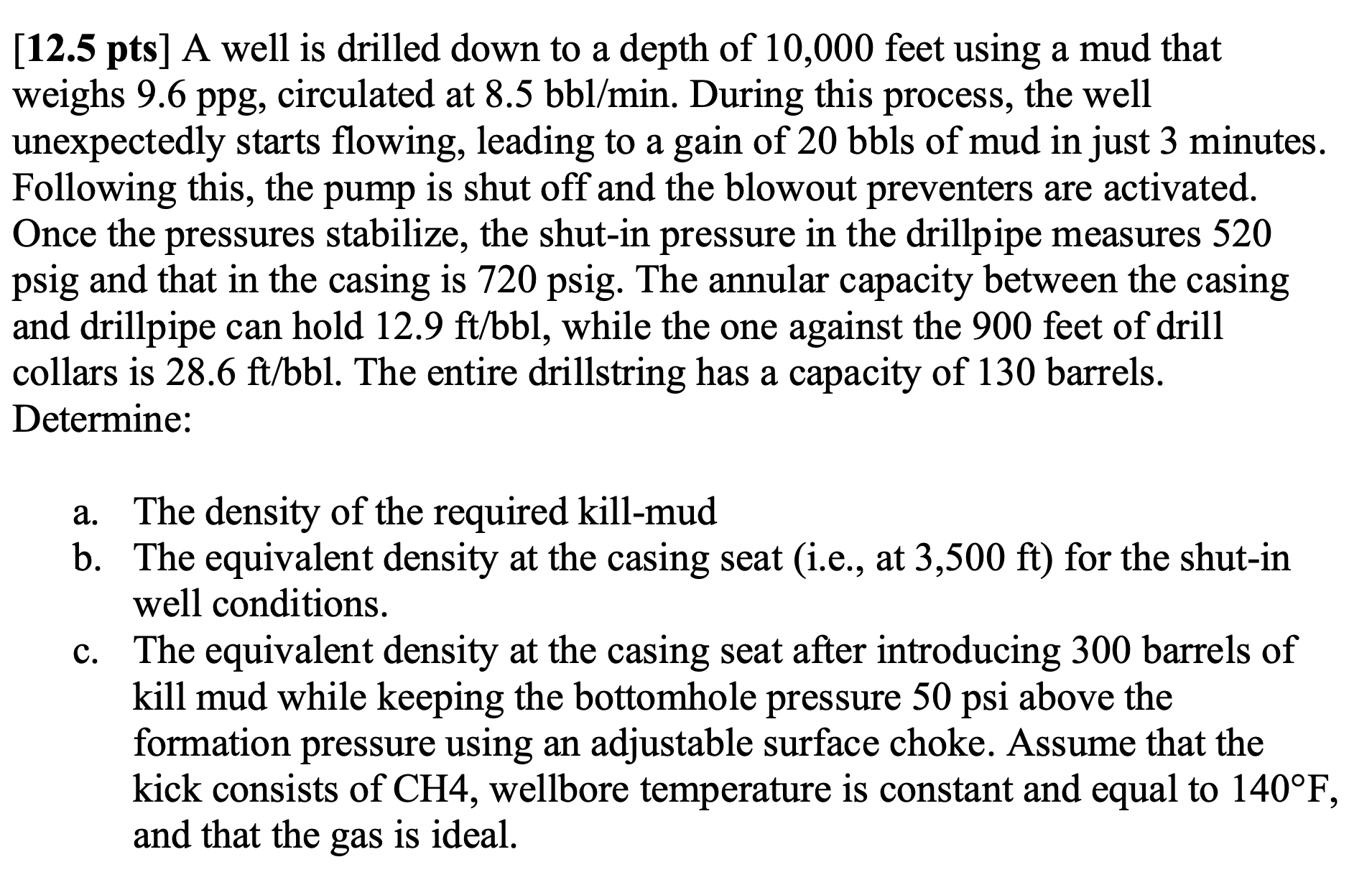

Question: Drilling Engineering: A well is drilled down to a depth of 1 0 , 0 0 0 feet using a mud that weighs 9 .

Drilling Engineering: A well is drilled down to a depth of feet using a mud that

weighs circulated at During this process, the well

unexpectedly starts flowing, leading to a gain of of mud in just minutes.

Following this, the pump is shut off and the blowout preventers are activated.

Once the pressures stabilize, the shutin pressure in the drillpipe measures

psig and that in the casing is The annular capacity between the casing

and drillpipe can hold while the one against the feet of drill

collars is The entire drillstring has a capacity of barrels.

Determine:

a The density of the required killmud

b The equivalent density at the casing seat ie at ft for the shutin

well conditions.

c The equivalent density at the casing seat after introducing barrels of

kill mud while keeping the bottomhole pressure above the

formation pressure using an adjustable surface choke. Assume that the

kick consists of wellbore temperature is constant and equal to

and that the gas is ideal.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock