Question: Due Date: After Session 7 ( Midnight ) A gas turbine engine works at constant speed at service temperature of 7 6 0 C .

Due Date: After Session Midnight

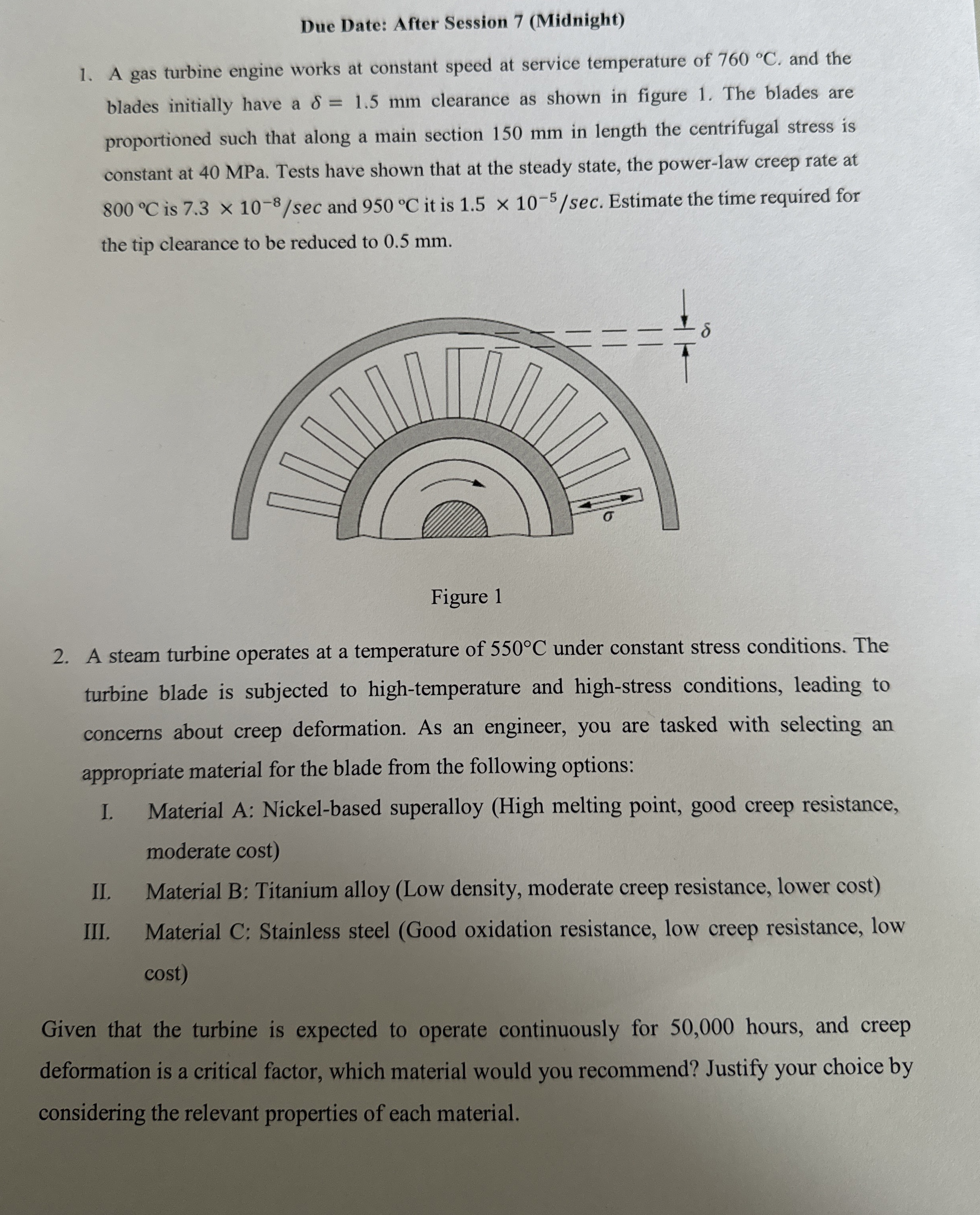

A gas turbine engine works at constant speed at service temperature of and the

blades initially have a clearance as shown in figure The blades are

proportioned such that along a main section mm in length the centrifugal stress is

constant at MPa Tests have shown that at the steady state, the powerlaw creep rate at

is and it is Estimate the time required for

the tip clearance to be reduced to mm

A steam turbine operates at a temperature of under constant stress conditions. The

turbine blade is subjected to hightemperature and highstress conditions, leading to

concerns about creep deformation. As an engineer, you are tasked with selecting an

appropriate material for the blade from the following options:

I. Material A: Nickelbased superalloy High melting point, good creep resistance,

moderate cost

II Material B: Titanium alloy Low density, moderate creep resistance, lower cost

III. Material C: Stainless steel Good oxidation resistance, low creep resistance, low

Given that the turbine is expected to operate continuously for hours, and creep

deformation is a critical factor, which material would you recommend? Justify your choice by

considering the relevant properties of each material.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock