Question: due dates should be minutes not hours E HAS DUE DATES 120,150,90,210,150 RESPECTIVELY Suppose that the FCC Company manufactures several products on make-to-order basis. An

due dates should be minutes not hours

due dates should be minutes not hours

E HAS DUE DATES 120,150,90,210,150 RESPECTIVELY

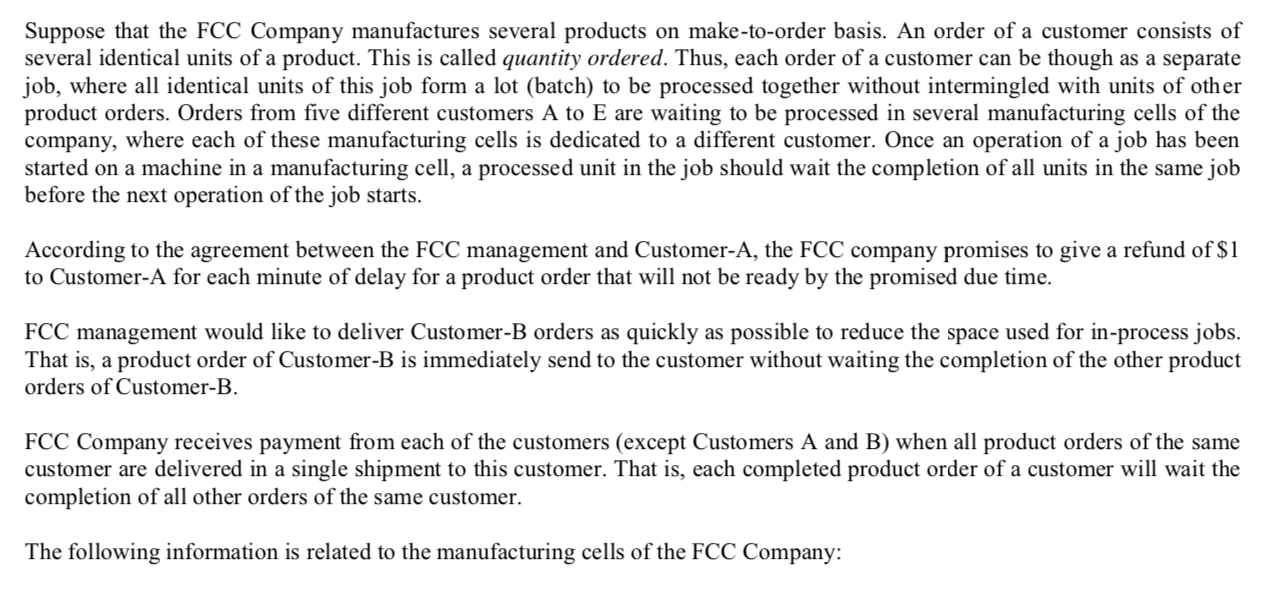

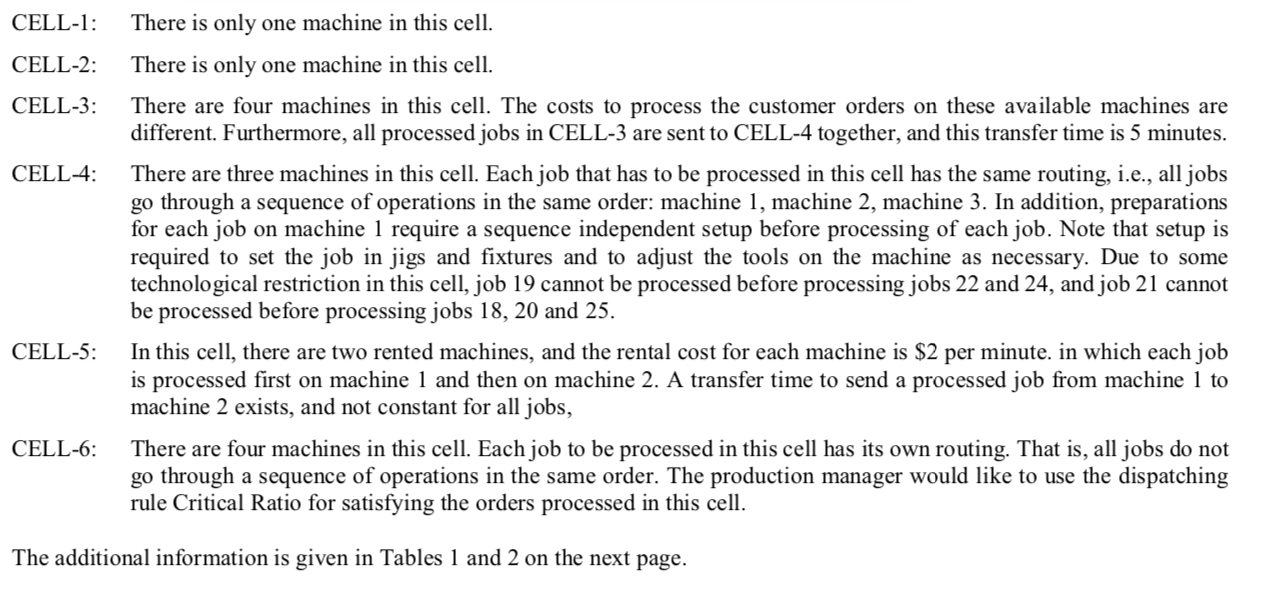

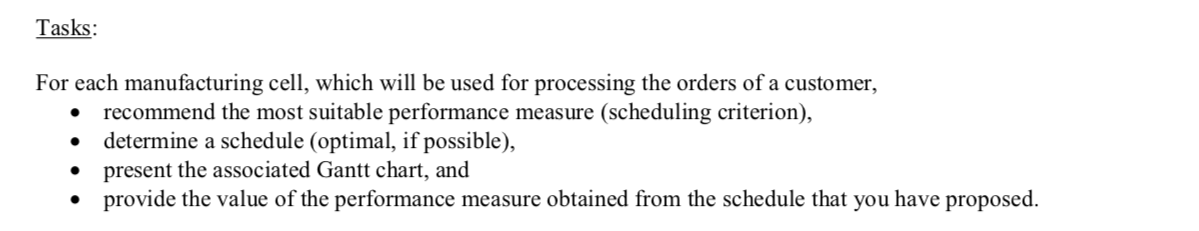

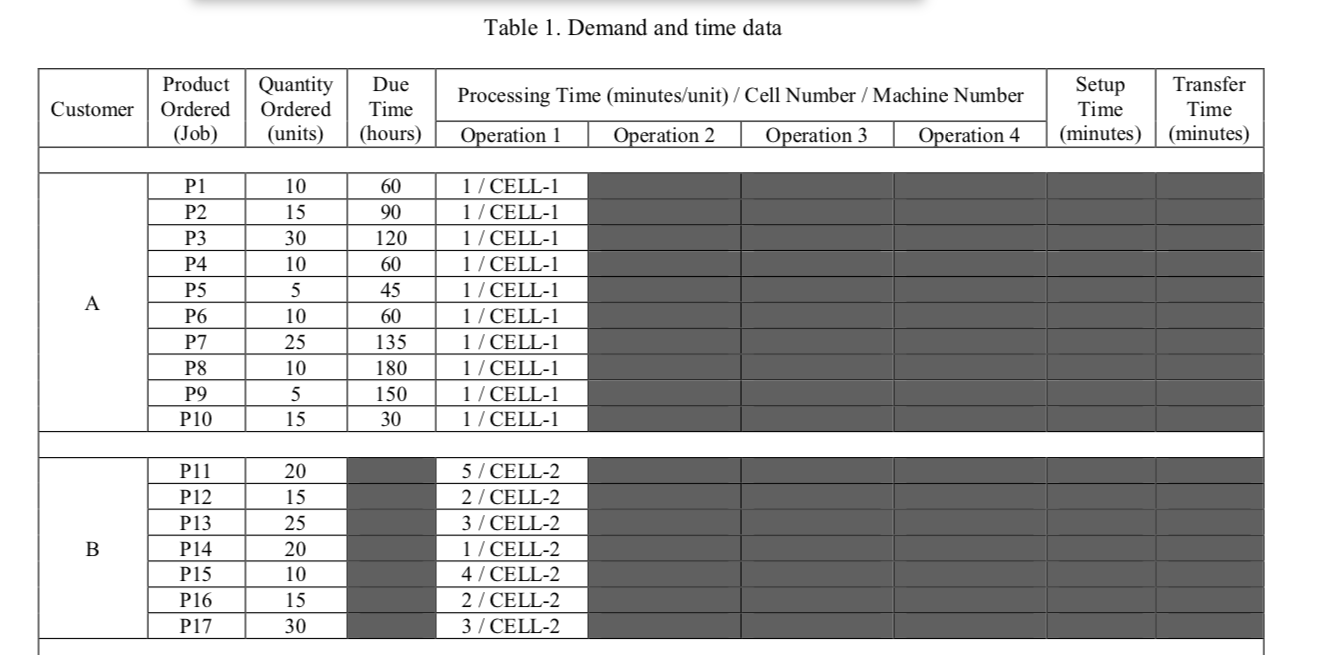

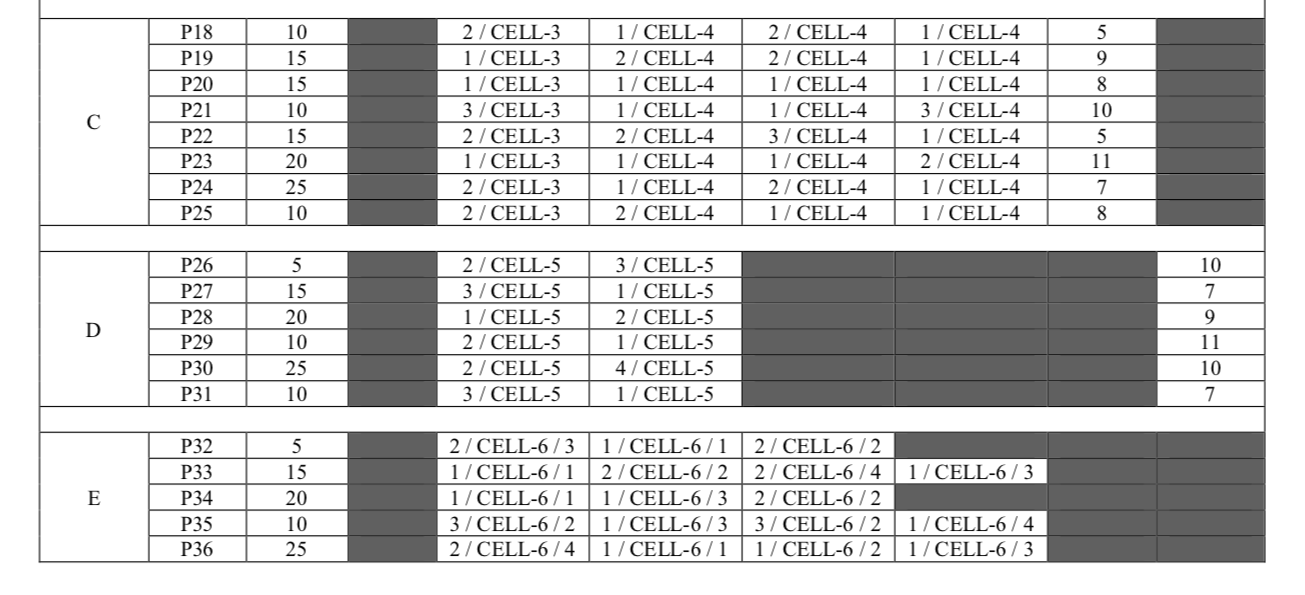

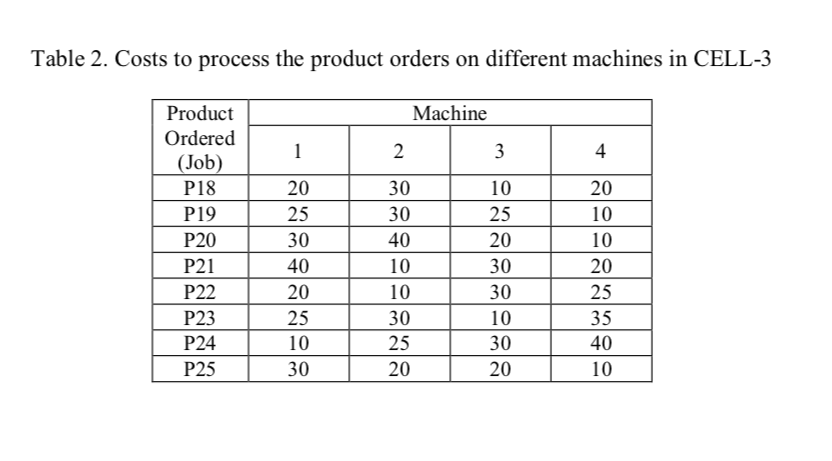

Suppose that the FCC Company manufactures several products on make-to-order basis. An order of a customer consists of several identical units of a product. This is called quantity ordered. Thus, each order of a customer can be though as a separate job, where all identical units of this job form a lot (batch) to be processed together without intermingled with units of other product orders. Orders from five different customers A to E are waiting to be processed in several manufacturing cells of the company, where each of these manufacturing cells is dedicated to a different customer. Once an operation of a job has been started on a machine in a manufacturing cell, a processed unit in the job should wait the completion of all units in the same job before the next operation of the job starts. According to the agreement between the FCC management and Customer-A, the FCC company promises to give a refund of $1 to Customer-A for each minute of delay for a product order that will not be ready by the promised due time. FCC management would like to deliver Customer-B orders as quickly as possible to reduce the space used for in-process jobs. That is, a product order of Customer-B is immediately send to the customer without waiting the completion of the other product orders of Customer-B. FCC Company receives payment from each of the customers (except Customers A and B) when all product orders of the same customer are delivered in a single shipment to this customer. That is, each completed product order of a customer will wait the completion of all other orders of the same customer. The following information is related to the manufacturing cells of the FCC Company: CELL-1: CELL-2: CELL-3: CELL-4: There is only one machine in this cell. There is only one machine in this cell. There are four machines in this cell. The costs to process the customer orders on these available machines are different. Furthermore, all processed jobs in CELL-3 are sent to CELL-4 together, and this transfer time is 5 minutes. There are three machines in this cell. Each job that has to be processed in this cell has the same routing, i.e., all jobs go through a sequence of operations in the same order: machine 1, machine 2, machine 3. In addition, preparations for each job on machine 1 require a sequence independent setup before processing of each job. Note that setup is required to set the job in jigs and fixtures and to adjust the tools on the machine as necessary. Due to some technological restriction in this cell, job 19 cannot be processed before processing jobs 22 and 24, and job 21 cannot be processed before processing jobs 18, 20 and 25. In this cell, there are two rented machines, and the rental cost for each machine is $2 per minute in which each job is processed first on machine 1 and then on machine 2. A transfer time to send a processed job from machine 1 to machine 2 exists, and not constant for all jobs, There are four machines in this cell. Each job to be processed in this cell has its own routing. That is, all jobs do not go through a sequence of operations in the same order. The production manager would like to use the dispatching rule Critical Ratio for satisfying the orders processed in this cell. CELL-5: CELL-6: The additional information is given in Tables 1 and 2 on the next page. Tasks: For each manufacturing cell, which will be used for processing the orders of a customer, recommend the most suitable performance measure (scheduling criterion), determine a schedule (optimal, if possible), present the associated Gantt chart, and provide the value of the performance measure obtained from the schedule that you have proposed. . Table 1. Demand and time data Customer Product Ordered (Job) Quantity Ordered (units) Due Time (hours) Processing Time (minutes/unit) / Cell Number / Machine Number Operation 1 Operation 2 Operation 3 Operation 4 Setup Time (minutes) Transfer Time (minutes) A P1 P2 P3 P4 P5 P6 P7 P8 P9 P10 10 15 30 10 5 10 25 10 5 15 60 90 120 60 45 60 135 180 150 30 1/CELL-1 1/CELL-1 1/CELL-1 1/CELL-1 1/CELL-1 1/CELL-1 1/CELL-1 1/CELL-1 1/CELL-1 1/CELL-1 B P11 P12 P13 P14 P15 P16 P17 20 15 25 20 10 15 30 5 / CELL-2 2 / CELL-2 3 / CELL-2 1/CELL-2 4 / CELL-2 2 / CELL-2 3/ CELL-2 P18 P19 P20 P21 P22 P23 P24 P25 10 15 15 10 15 20 25 10 2 / CELL-3 1/CELL-3 1/CELL-3 3/ CELL-3 2 / CELL-3 1/CELL-3 2 / CELL-3 2 / CELL-3 1/ CELL-4 2 / CELL-4 1/ CELL-4 1/ CELL-4 2 / CELL-4 1/ CELL-4 1/ CELL-4 2/ CELL-4 2 / CELL-4 2 / CELL-4 1/ CELL-4 1/ CELL-4 3/ CELL-4 1/ CELL-4 2 / CELL-4 1/ CELL-4 1/CELL-4 1/CELL-4 1/CELL-4 3/ CELL-4 1/CELL-4 2 / CELL-4 1/CELL-4 1/CELL-4 5 9 8 10 5 11 7 8 D P26 P27 P28 P29 P30 P31 5 15 20 10 25 10 2 / CELL-5 3/ CELL-5 1/CELL-5 2 / CELL-5 2 / CELL-5 3/ CELL-5 3/ CELL-5 1/ CELL-5 2 / CELL-5 1/ CELL-5 4/ CELL-5 1/ CELL-5 10 7 9 11 10 7 1/CELL-6/3 E P32 P33 P34 P35 P36 5 15 20 10 25 2 / CELL-6/3 1/CELL-6/1 1/CELL-6/1 3/ CELL-6/2 2/CELL-6/4 TI 1/CELL-6/1 2 / CELL-6/2 1/CELL-6/3 1/CELL-6/3 1/CELL-6/1 2 / CELL-6/2 2 / CELL-6/4 2 / CELL-6/2 3/ CELL-6/2 1/ CELL-6/2 1/CELL-6/4 1/CELL-6/3 Table 2. Costs to process the product orders on different machines in CELL-3 Machine 2 3 4 30 Product Ordered (Job) P18 P19 P20 P21 P22 P23 P24 P25 20 25 30 40 20 25 30 40 10 10 10 25 20 30 30 10 30 20 20 10 10 20 25 35 40 10 30 10 25 20 30 Suppose that the FCC Company manufactures several products on make-to-order basis. An order of a customer consists of several identical units of a product. This is called quantity ordered. Thus, each order of a customer can be though as a separate job, where all identical units of this job form a lot (batch) to be processed together without intermingled with units of other product orders. Orders from five different customers A to E are waiting to be processed in several manufacturing cells of the company, where each of these manufacturing cells is dedicated to a different customer. Once an operation of a job has been started on a machine in a manufacturing cell, a processed unit in the job should wait the completion of all units in the same job before the next operation of the job starts. According to the agreement between the FCC management and Customer-A, the FCC company promises to give a refund of $1 to Customer-A for each minute of delay for a product order that will not be ready by the promised due time. FCC management would like to deliver Customer-B orders as quickly as possible to reduce the space used for in-process jobs. That is, a product order of Customer-B is immediately send to the customer without waiting the completion of the other product orders of Customer-B. FCC Company receives payment from each of the customers (except Customers A and B) when all product orders of the same customer are delivered in a single shipment to this customer. That is, each completed product order of a customer will wait the completion of all other orders of the same customer. The following information is related to the manufacturing cells of the FCC Company: CELL-1: CELL-2: CELL-3: CELL-4: There is only one machine in this cell. There is only one machine in this cell. There are four machines in this cell. The costs to process the customer orders on these available machines are different. Furthermore, all processed jobs in CELL-3 are sent to CELL-4 together, and this transfer time is 5 minutes. There are three machines in this cell. Each job that has to be processed in this cell has the same routing, i.e., all jobs go through a sequence of operations in the same order: machine 1, machine 2, machine 3. In addition, preparations for each job on machine 1 require a sequence independent setup before processing of each job. Note that setup is required to set the job in jigs and fixtures and to adjust the tools on the machine as necessary. Due to some technological restriction in this cell, job 19 cannot be processed before processing jobs 22 and 24, and job 21 cannot be processed before processing jobs 18, 20 and 25. In this cell, there are two rented machines, and the rental cost for each machine is $2 per minute in which each job is processed first on machine 1 and then on machine 2. A transfer time to send a processed job from machine 1 to machine 2 exists, and not constant for all jobs, There are four machines in this cell. Each job to be processed in this cell has its own routing. That is, all jobs do not go through a sequence of operations in the same order. The production manager would like to use the dispatching rule Critical Ratio for satisfying the orders processed in this cell. CELL-5: CELL-6: The additional information is given in Tables 1 and 2 on the next page. Tasks: For each manufacturing cell, which will be used for processing the orders of a customer, recommend the most suitable performance measure (scheduling criterion), determine a schedule (optimal, if possible), present the associated Gantt chart, and provide the value of the performance measure obtained from the schedule that you have proposed. . Table 1. Demand and time data Customer Product Ordered (Job) Quantity Ordered (units) Due Time (hours) Processing Time (minutes/unit) / Cell Number / Machine Number Operation 1 Operation 2 Operation 3 Operation 4 Setup Time (minutes) Transfer Time (minutes) A P1 P2 P3 P4 P5 P6 P7 P8 P9 P10 10 15 30 10 5 10 25 10 5 15 60 90 120 60 45 60 135 180 150 30 1/CELL-1 1/CELL-1 1/CELL-1 1/CELL-1 1/CELL-1 1/CELL-1 1/CELL-1 1/CELL-1 1/CELL-1 1/CELL-1 B P11 P12 P13 P14 P15 P16 P17 20 15 25 20 10 15 30 5 / CELL-2 2 / CELL-2 3 / CELL-2 1/CELL-2 4 / CELL-2 2 / CELL-2 3/ CELL-2 P18 P19 P20 P21 P22 P23 P24 P25 10 15 15 10 15 20 25 10 2 / CELL-3 1/CELL-3 1/CELL-3 3/ CELL-3 2 / CELL-3 1/CELL-3 2 / CELL-3 2 / CELL-3 1/ CELL-4 2 / CELL-4 1/ CELL-4 1/ CELL-4 2 / CELL-4 1/ CELL-4 1/ CELL-4 2/ CELL-4 2 / CELL-4 2 / CELL-4 1/ CELL-4 1/ CELL-4 3/ CELL-4 1/ CELL-4 2 / CELL-4 1/ CELL-4 1/CELL-4 1/CELL-4 1/CELL-4 3/ CELL-4 1/CELL-4 2 / CELL-4 1/CELL-4 1/CELL-4 5 9 8 10 5 11 7 8 D P26 P27 P28 P29 P30 P31 5 15 20 10 25 10 2 / CELL-5 3/ CELL-5 1/CELL-5 2 / CELL-5 2 / CELL-5 3/ CELL-5 3/ CELL-5 1/ CELL-5 2 / CELL-5 1/ CELL-5 4/ CELL-5 1/ CELL-5 10 7 9 11 10 7 1/CELL-6/3 E P32 P33 P34 P35 P36 5 15 20 10 25 2 / CELL-6/3 1/CELL-6/1 1/CELL-6/1 3/ CELL-6/2 2/CELL-6/4 TI 1/CELL-6/1 2 / CELL-6/2 1/CELL-6/3 1/CELL-6/3 1/CELL-6/1 2 / CELL-6/2 2 / CELL-6/4 2 / CELL-6/2 3/ CELL-6/2 1/ CELL-6/2 1/CELL-6/4 1/CELL-6/3 Table 2. Costs to process the product orders on different machines in CELL-3 Machine 2 3 4 30 Product Ordered (Job) P18 P19 P20 P21 P22 P23 P24 P25 20 25 30 40 20 25 30 40 10 10 10 25 20 30 30 10 30 20 20 10 10 20 25 35 40 10 30 10 25 20 30Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts