Question: Electropolishing is a well - known method for improving the surface finish of a metallic component. Through detailed electrochemical studies, it has been found that

Electropolishing is a wellknown method for improving the surface finish of a metallic component.

Through detailed electrochemical studies, it has been found that during electropolishing of

copper parts in a phosphoric acidbased solution, the diffusion of copper phosphate species

determines the rate of electropolishing.

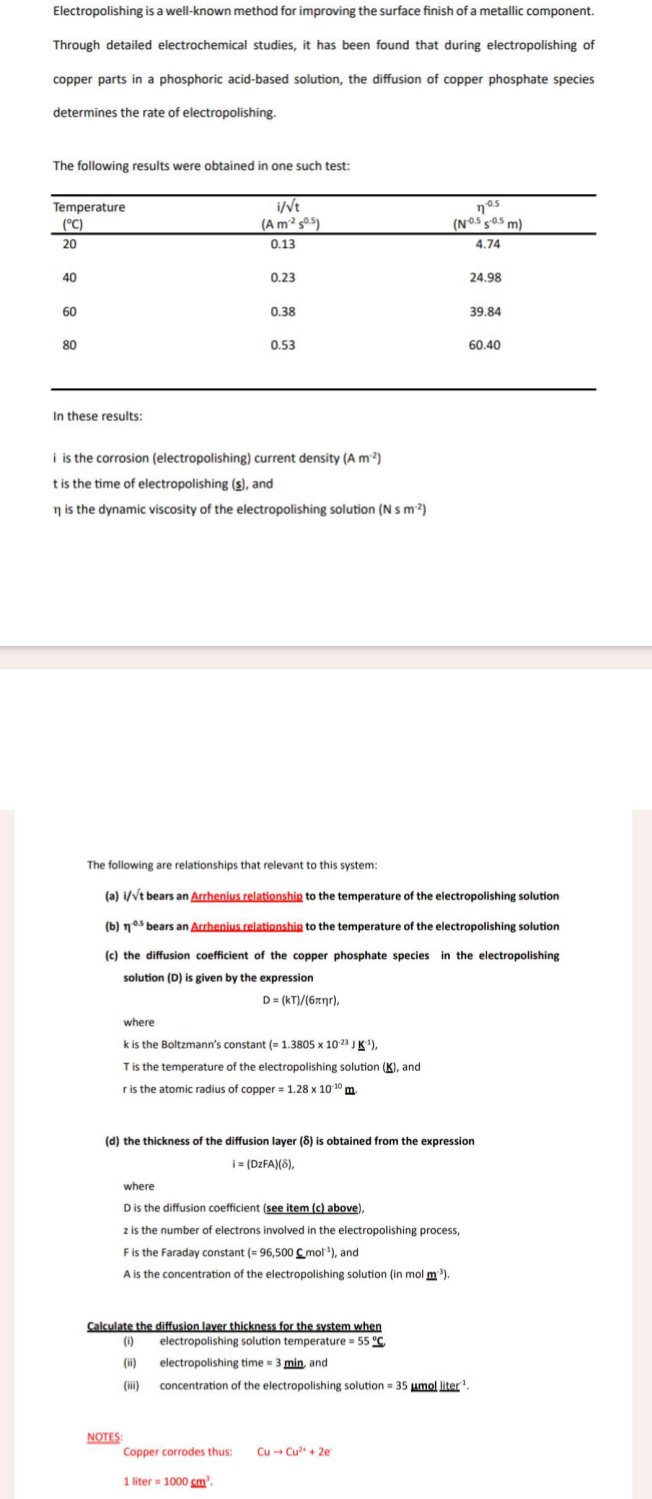

The following results were obtained in one such test:

In these results:

i is the corrosion electropolishing current density

is the time of electropolishing s and

is the dynamic viscosity of the electropolishing solution

The following are relationships that relevant to this system:

a t bears an Arrhenius relationship to the temperature of the electropolishing solution

b bears an Arrhenius relationshig to the temperature of the electropolishing solution

c the diffusion coefficient of the copper phosphate species in the electropolishing

solution D is given by the expression

where

k is the Boltzmann's constant

is the temperature of the electropolishing solution and

r is the atomic radius of copper

d the thickness of the diffusion layer is obtained from the expression

where

D is the diffusion coefficient see item c above

is the number of electrons involved in the electropolishing process,

is the concentration of the electropolishing solution in

Calculate the diffusion laver thickness for the system when

i electropolishing solution temperature

ii electropolishing time min, and

iii concentration of the electropolishing solution umol liter

NOTES:

Copper corrodes thus:

liter

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock