Question: Energy conversion processes Assignment 2 : Waste heat recovery with ORC - process 1 INTRODUCTION In this assignment, we consider the conversion of industrial waste

Energy conversion processes

Assignment : Waste heat recovery with ORCprocess

INTRODUCTION

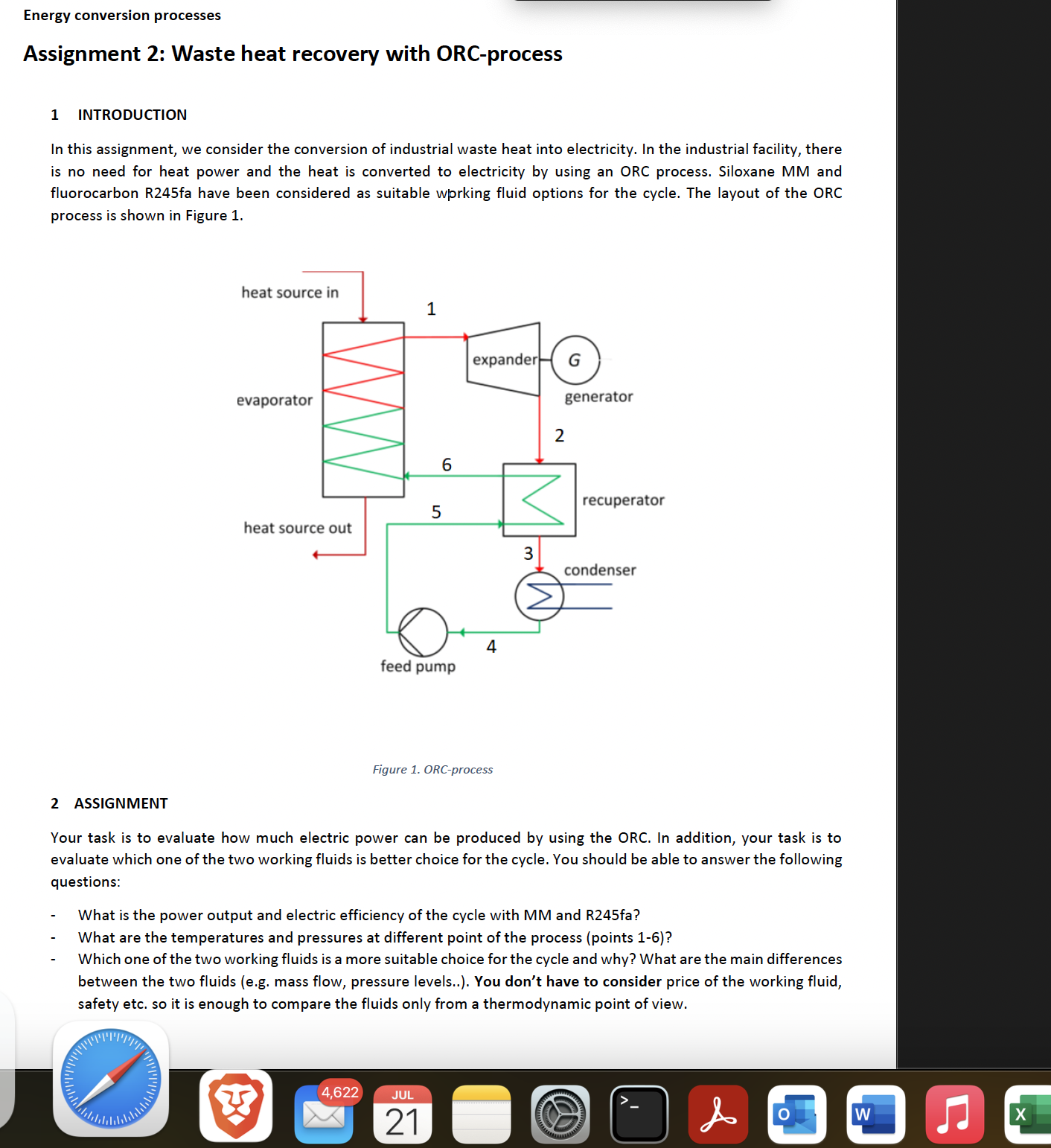

In this assignment, we consider the conversion of industrial waste heat into electricity. In the industrial facility, there is no need for heat power and the heat is converted to electricity by using an ORC process. Siloxane MM and fluorocarbon Rfa have been considered as suitable wprking fluid options for the cycle. The layout of the ORC process is shown in Figure

Figure ORCprocess

ASSIGNMENT

Your task is to evaluate how much electric power can be produced by using the ORC. In addition, your task is to evaluate which one of the two working fluids is better choice for the cycle. You should be able to answer the following questions:

What is the power output and electric efficiency of the cycle with MM and Rfa

What are the temperatures and pressures at different point of the process points

Which one of the two working fluids is a more suitable choice for the cycle and why? What are the main differences between the two fluids eg mass flow, pressure levels.. You don't have to consider price of the working fluid, safety etc. so it is enough to compare the fluids only from a thermodynamic point of view. CALCULATIONS

There are the log diagrams of the fluids given and you can use these diagrams in defining the required

thermodynamic properties. Note that the pressure is given in logarithmic scale and it represents the absolute

pressure.

You can make the following simplifications and assumptions:

No heat losses

No pressure losses

Working fluid is superheated by K before the expander point

Working fluid is saturated liquid at the condenser outletpoint

Temperature rise in feed pump is not significant lets assume T T

Density of the liquid is assumed as constant over the pump and the same density is used for both fluids to simplify

the calculation.

Only subcritical cycles are considered evaporator pressure and temperature must be kept below the critical point

of the fluid.

Initial values for calculations:

Specific heat capacity of the waste heat constant

Waste heat temperature at the evaporator outlet

Average liquid density in feed pump

Feed pump efficiency

Generator efficiency

Degree of recuperation

You can find rest of your initial values based on your surname.

HELP AND TIPS FOR SOLVING THE PROBLEM:

You can start by making a sketch of the cycle on log p h diagrams. First, select a suitable evaporating temperature. In

general the higher the evaporator temperature, the higher of the cycle efficiency and power output. Based on the

selected evaporating temperature you can define the corresponding pressure level pressure at points and You

can also define the expander inlet state now by taking into account the degree of superheating. Condensing

temperature is given in the initial values pressure at points and can be defined based on this information. To solve the expansion process in the expander, follow the constant entropy line from point to pressure this is

point s From this point you can define the expander isentropic outlet enthalpy Based on the turbineexpander

efficiency and the isentropic enthalpy change h can be solved.

The enthalpy change in feed pump can be solved as the condensing pressure and evaporation pressure are known:

Working fluid temperature at point can be solved from the definition of the degree of recuperation:

When h and h are known, you can solve and draw the temperature diagram of the evaporator and also solve the

pinch point. Look example from the ORC exercises remember to take into account also the superheating and liquid

preheating in the recuperator If the temperature differences between the working fluid and waste heat source are

large, you can increase the evaporation pressure and recalculate the cycle. The evaporator heat rate can be calculated

by using following equation:

FINAL REPORT AND OTHER INITIAL VALUES

Your final report should include the following information:

Your initial values

The most important equations you have been using

Results in a table including the process values, power output, turbine power, feed pump power and cycle

efficiency

Log drawings with the processes illustrated

Evaporator temperature diagram heat power on axis and pinch point temperature difference

Selection of working fluid. Which one of the two working fluids seems to be a better choice and why? What

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock