Question: Engineering Management project plan and risk analysis coursework 2 Your Task You are a business consultant and project manager. You have been approached by a

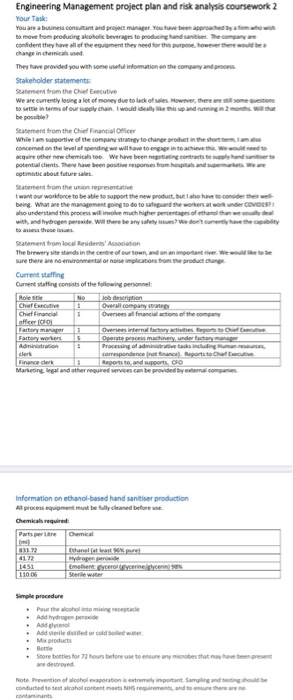

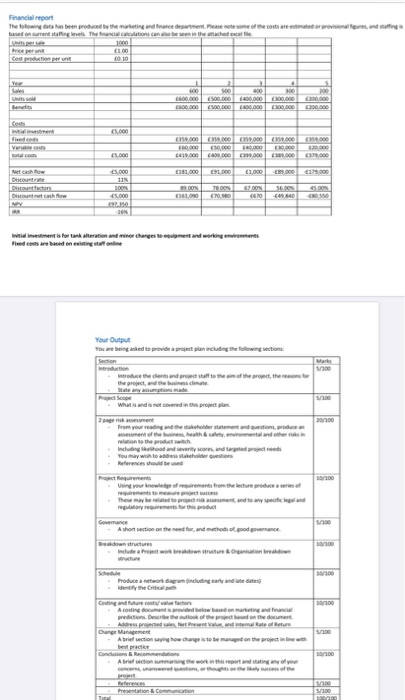

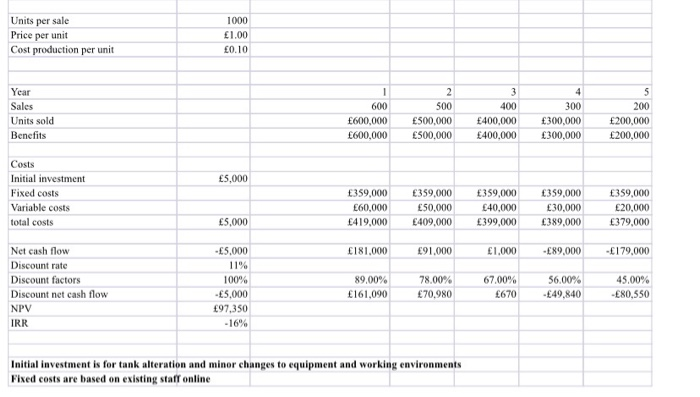

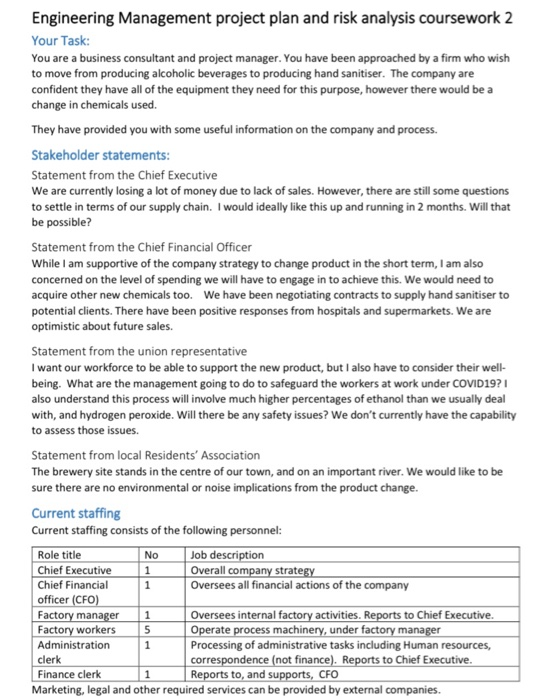

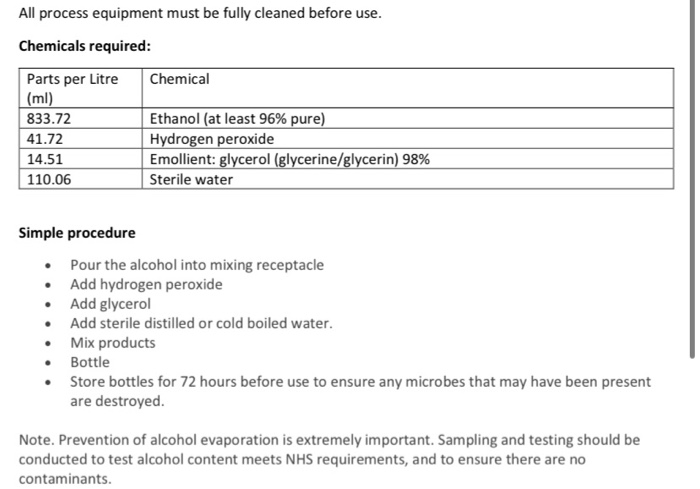

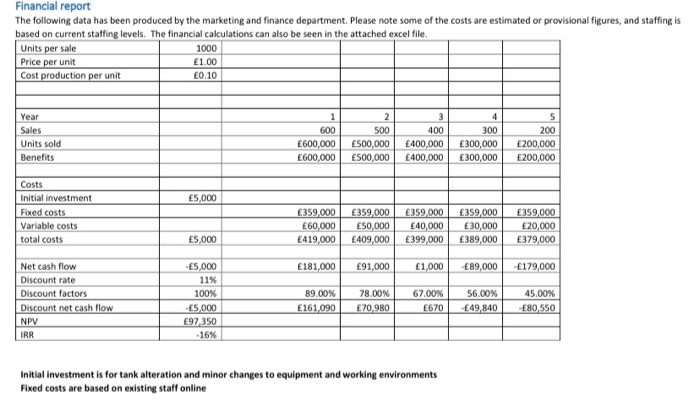

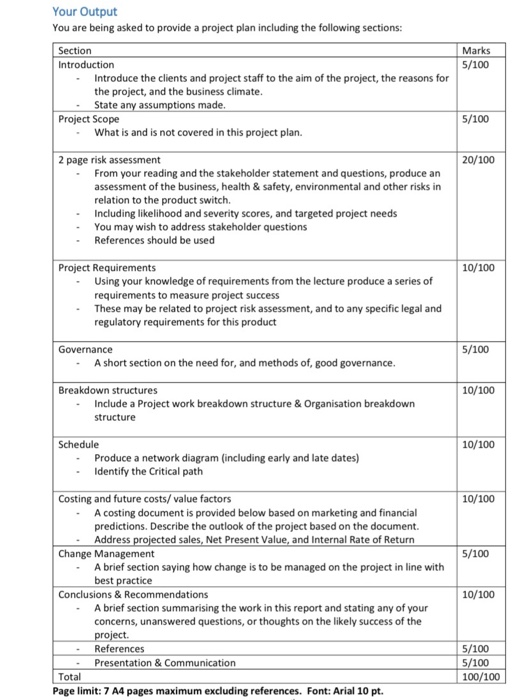

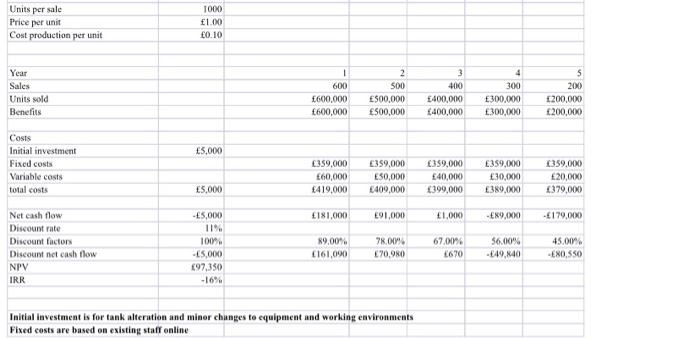

Engineering Management project plan and risk analysis coursework 2 Your Task You are a business consultant and project manager. You have been approached by a who to move from producing alcoholic beverages to producing and sanitiset. The company we confident they have all of the comment they need for the purpose. However there would be change in chemicals used They have provided you with some information on the company and process Stakeholder statements: Statement from the Chief Executive We are currently losing a lot of money due to lack of sales. However, there are still some questions to settle in terms of our chain. I would all this up and running in 2 months with be possible? Statement from the Chief Financial Officer While iam supportive of the company strategy to change product in the short term.lamaise concerned on the level of spending we will have to engage into achieve that we would need to acquire other new chemicals toe. We have been negotiating contracts to hand site potential clients. There have been positive response from hospitals and me optimistic about future sales Statement from the Union representative I want our workforce to be able to support the new product, but also have to consider their being. What are the management going to do to safeguard the workers at work under COVORSI who understand this process will involve much higher percentages of ethanol handel with, and hydrogen peroxide. Will there be any safety document have the ability to the Statement from local Residents Association The brewery site stands in the centre of our town, and on an important river. We would sure there are no environmental or noise implications from the product change Current staffing Current stating consists of the following personnel Job description Chief Executive Overall company state Chief Financial Oversees al financial actions of the company officer CEOL Factory manager Ourses internal factory in Bapers to Culture Factory workers Operate process machinery, under factory manager Administration B Processing of administration takes induding clerk correspondence notare). Reports to the France Clerk Reports to and supports 650 Marketing legal and other required services can be provided by external companies 1 Information on ethanol-based and sanitiser production Al process equipment must be fully cleaned before use. Chemikals required Parts per Lire Chemical 1451 11000 Emellent concern Serie water Simple procedure Add hydrogen peroxid Adel Adrerile din led or cold sold water Me products Store bottles for 72 hours before or any microbes that may have been present are destroyed Note. Prevention of alcohol evaporation is extremely important samling and hold be conducted to test alcohol content meet requirements, and to the contaminants Financial report The following data has been produced by the marketing and France dement. Perete some of the costs are estimated or progres, and staffing based on current stages. The financial Calculations can be seen in the attached Price per Costruit 010 units 100 0.000 LSDO 200 0.000 SOO DOO 400 100.000 LADD000 0.000 EN DOO 65.000 30 sota ES DO 000 1361.000 179,000 5.000 118 399.00 Discount Discount factors Drottnet anhow BEY 78.00 E70,90 6570 0940 Fred cests are based on ingle Your Output Tou are being asked to provide a project plan including the following sections Introduce the end of the mother, the the project, and the businessmate State any milions made 2010 Page riH HAmert From your reading and the stakeholder statement and to produce You may wish to sholdereito 30 Using your knowledge of requirements from the lecture produce a series of These may be red to presente anche A short action on the need for and methodolgood governance Trawn structures indude woorden Schedule Produce a network degandung und die Coming and More col factors A conting document provided below based on and financial prediction Describe the outlook of the probased on the document . Address procedit Penal, temalte Betum Change Management A brief section saying how changes to be managed on the project inline best practice Candions & Recommend A brief section in the work in this report and stating any of your 10300 Presentation & Communication 7300 Units per sale Price per unit Cost production per unit 1000 1.00 0.10 1 4 Year Sales Units sold Benefits 600 600,000 600,000 2 500 500,000 500.000 3 400 400,000 400,000 300 300,000 300,000 5 200 200,000 200,000 5,000 Costs Initial investment Fixed costs Variable costs total costs 359,000 60,000 419,000 359,000 50,000 409,000 359,000 40,000 399,000 359,000 30,000 389,000 359,000 20,000 379,000 5,000 181,000 91.000 1,000 -89,000 - 179.000 Net cash flow Discount rate Discount factors Discount net cash flow NPV IRR -5,000 11% 100% - 5,000 97,350 -16% 89.00% 161,090 78.00% 70,980 67.00% 670 56.00% - 49.840 45.00% -80,550 Initial investment is for tank alteration and minor changes to equipment and working environments Fixed costs are based on existing staff online Engineering Management project plan and risk analysis coursework 2 Your Task: You are a business consultant and project manager. You have been approached by a firm who wish to move from producing alcoholic beverages to producing hand sanitiser. The company are confident they have all of the equipment they need for this purpose, however there would be a change in chemicals used. They have provided you with some useful information on the company and process. Stakeholder statements: Statement from the Chief Executive We are currently losing a lot of money due to lack of sales. However, there are still some questions to settle in terms of our supply chain. I would ideally like this up and running in 2 months. Will that be possible? Statement from the Chief Financial Officer While I am supportive of the company strategy to change product in the short term, I am also concerned on the level of spending we will have to engage in to achieve this. We would need to acquire other new chemicals too. We have been negotiating contracts to supply hand sanitiser to potential clients. There have been positive responses from hospitals and supermarkets. We are optimistic about future sales. Statement from the union representative I want our workforce to be able to support the new product, but I also have to consider their well- being. What are the management going to do to safeguard the workers at work under COVID19? I also understand this process will involve much higher percentages of ethanol than we usually deal with, and hydrogen peroxide. Will there be any safety issues? We don't currently have the capability to assess those issues. Statement from local Residents' Association The brewery site stands in the centre of our town, and on an important river. We would like to be sure there are no environmental or noise implications from the product change. Current staffing Current staffing consists of the following personnel: Role title Job description Chief Executive Overall company strategy Chief Financial Oversees all financial actions of the company officer (CFO) Factory manager Oversees internal factory activities. Reports to Chief Executive. Factory workers Operate process machinery, under factory manager Administration Processing of administrative tasks including Human resources, clerk correspondence (not finance). Reports to Chief Executive. Finance clerk Reports to, and supports, CFO Marketing, legal and other required services can be provided by external companies. No 1 1 1 5 1 1 All process equipment must be fully cleaned before use. Chemicals required: Parts per Litre Chemical (ml) 833.72 Ethanol (at least 96% pure) 41.72 Hydrogen peroxide 14.51 Emollient: glycerol (glycerine/glycerin) 98% 110.06 Sterile water Simple procedure Pour the alcohol into mixing receptacle Add hydrogen peroxide Add glycerol Add sterile distilled or cold boiled water. Mix products Bottle Store bottles for 72 hours before use to ensure any microbes that may have been present are destroyed. Note. Prevention of alcohol evaporation is extremely important. Sampling and testing should be conducted to test alcohol content meets NHS requirements, and to ensure there are no contaminants. Financial report The following data has been produced by the marketing and finance department. Please note some of the costs are estimated or provisional figures, and staffing is based on current staffing levels. The financial calculations can also be seen in the attached excel file. Units per sale 1000 Price per unit Cost production per unit 0.10 1.00 1 Year Sales Units sold Benefits 600 600,000 600,000 2 500 500,000 500,000 3 400 400,000 400,000 4 300 300,000 300,000 5 200 200,000 200,000 5,000 Costs Initial investment Fixed costs Variable costs total costs 359,000 60,000 419,000 359,000 50,000 409,000 359,000 40,000 399,000 359,000 30,000 389,000 359,000 20,000 379,000 5,000 E181,000 91,000 1,000 -89,000 -179,000 Net cash flow Discount rate Discount factors Discount net cash flow NPV IRR -5,000 11% 100% -5,000 97,350 -16% 89.00% 161,090 78.00% 70,980 67.00% 670 56.00% 49,840 45.00% 80,550 Initial investment is for tank alteration and minor changes to equipment and working environments Fixed costs are based on existing staff online Marks 5/100 5/100 20/100 10/100 Your Output You are being asked to provide a project plan including the following sections: Section Introduction Introduce the clients and project staff to the aim of the project, the reasons for the project, and the business climate. State any assumptions made. Project Scope What is and is not covered in this project plan. 2 page risk assessment From your reading and the stakeholder statement and questions, produce an assessment of the business, health & safety, environmental and other risks in relation to the product switch. Including likelihood and severity scores, and targeted project needs You may wish to address stakeholder questions References should be used Project Requirements Using your knowledge of requirements from the lecture produce a series of requirements to measure project success These may be related to project risk assessment, and to any specific legal and regulatory requirements for this product Governance A short section on the need for, and methods of, good governance. Breakdown structures Include a Project work breakdown structure & Organisation breakdown structure Schedule Produce a network diagram (including early and late dates) Identify the Critical path Costing and future costs/ value factors A costing document is provided below based on marketing and financial predictions. Describe the outlook of the project based on the document. Address projected sales, Net Present Value, and Internal Rate of Return Change Management A brief section saying how change is to be managed on the project in line with best practice Conclusions & Recommendations A brief section summarising the work in this report and stating any of your concerns, unanswered questions, or thoughts on the likely success of the project. References Presentation & Communication Total Page limit: 7 A4 pages maximum excluding references. Font: Arial 10 pt. 5/100 10/100 10/100 10/100 5/100 10/100 5/100 5/100 100/100 Units per sale Price per unit Cost production per unit 1000 1.00 0.10 Year Sales Units sold Benefits 600 600,000 600,000 2 500 500,000 500,000 3 400 400,000 400,000 4 300 300,000 300,000 5 200 200,000 200,000 5,000 Costs Initial investment Fixed costs Variable costs total costs 359,000 60,000 419.000 359,000 50,000 409,000 359,000 40,000 399,000 359,000 30,000 389,000 359,000 20,000 379,000 5,000 - 5,000 181,000 91,000 1,000 -89,000 -179,000 Net cash flow Discount rate Discount factors Discount net cash flow NPV IRR 89,00% 161,090 78.00% 70,980 67.00% 670 56.00% - 49,840 45.00% -80,550 100% -5,000 97,350 -16% Initial investment is for tank alteration and minor changes to equipment and working environments Fixed costs are based on existing staff online Engineering Management project plan and risk analysis coursework 2 Your Task You are a business consultant and project manager. You have been approached by a who to move from producing alcoholic beverages to producing and sanitiset. The company we confident they have all of the comment they need for the purpose. However there would be change in chemicals used They have provided you with some information on the company and process Stakeholder statements: Statement from the Chief Executive We are currently losing a lot of money due to lack of sales. However, there are still some questions to settle in terms of our chain. I would all this up and running in 2 months with be possible? Statement from the Chief Financial Officer While iam supportive of the company strategy to change product in the short term.lamaise concerned on the level of spending we will have to engage into achieve that we would need to acquire other new chemicals toe. We have been negotiating contracts to hand site potential clients. There have been positive response from hospitals and me optimistic about future sales Statement from the Union representative I want our workforce to be able to support the new product, but also have to consider their being. What are the management going to do to safeguard the workers at work under COVORSI who understand this process will involve much higher percentages of ethanol handel with, and hydrogen peroxide. Will there be any safety document have the ability to the Statement from local Residents Association The brewery site stands in the centre of our town, and on an important river. We would sure there are no environmental or noise implications from the product change Current staffing Current stating consists of the following personnel Job description Chief Executive Overall company state Chief Financial Oversees al financial actions of the company officer CEOL Factory manager Ourses internal factory in Bapers to Culture Factory workers Operate process machinery, under factory manager Administration B Processing of administration takes induding clerk correspondence notare). Reports to the France Clerk Reports to and supports 650 Marketing legal and other required services can be provided by external companies 1 Information on ethanol-based and sanitiser production Al process equipment must be fully cleaned before use. Chemikals required Parts per Lire Chemical 1451 11000 Emellent concern Serie water Simple procedure Add hydrogen peroxid Adel Adrerile din led or cold sold water Me products Store bottles for 72 hours before or any microbes that may have been present are destroyed Note. Prevention of alcohol evaporation is extremely important samling and hold be conducted to test alcohol content meet requirements, and to the contaminants Financial report The following data has been produced by the marketing and France dement. Perete some of the costs are estimated or progres, and staffing based on current stages. The financial Calculations can be seen in the attached Price per Costruit 010 units 100 0.000 LSDO 200 0.000 SOO DOO 400 100.000 LADD000 0.000 EN DOO 65.000 30 sota ES DO 000 1361.000 179,000 5.000 118 399.00 Discount Discount factors Drottnet anhow BEY 78.00 E70,90 6570 0940 Fred cests are based on ingle Your Output Tou are being asked to provide a project plan including the following sections Introduce the end of the mother, the the project, and the businessmate State any milions made 2010 Page riH HAmert From your reading and the stakeholder statement and to produce You may wish to sholdereito 30 Using your knowledge of requirements from the lecture produce a series of These may be red to presente anche A short action on the need for and methodolgood governance Trawn structures indude woorden Schedule Produce a network degandung und die Coming and More col factors A conting document provided below based on and financial prediction Describe the outlook of the probased on the document . Address procedit Penal, temalte Betum Change Management A brief section saying how changes to be managed on the project inline best practice Candions & Recommend A brief section in the work in this report and stating any of your 10300 Presentation & Communication 7300 Units per sale Price per unit Cost production per unit 1000 1.00 0.10 1 4 Year Sales Units sold Benefits 600 600,000 600,000 2 500 500,000 500.000 3 400 400,000 400,000 300 300,000 300,000 5 200 200,000 200,000 5,000 Costs Initial investment Fixed costs Variable costs total costs 359,000 60,000 419,000 359,000 50,000 409,000 359,000 40,000 399,000 359,000 30,000 389,000 359,000 20,000 379,000 5,000 181,000 91.000 1,000 -89,000 - 179.000 Net cash flow Discount rate Discount factors Discount net cash flow NPV IRR -5,000 11% 100% - 5,000 97,350 -16% 89.00% 161,090 78.00% 70,980 67.00% 670 56.00% - 49.840 45.00% -80,550 Initial investment is for tank alteration and minor changes to equipment and working environments Fixed costs are based on existing staff online Engineering Management project plan and risk analysis coursework 2 Your Task: You are a business consultant and project manager. You have been approached by a firm who wish to move from producing alcoholic beverages to producing hand sanitiser. The company are confident they have all of the equipment they need for this purpose, however there would be a change in chemicals used. They have provided you with some useful information on the company and process. Stakeholder statements: Statement from the Chief Executive We are currently losing a lot of money due to lack of sales. However, there are still some questions to settle in terms of our supply chain. I would ideally like this up and running in 2 months. Will that be possible? Statement from the Chief Financial Officer While I am supportive of the company strategy to change product in the short term, I am also concerned on the level of spending we will have to engage in to achieve this. We would need to acquire other new chemicals too. We have been negotiating contracts to supply hand sanitiser to potential clients. There have been positive responses from hospitals and supermarkets. We are optimistic about future sales. Statement from the union representative I want our workforce to be able to support the new product, but I also have to consider their well- being. What are the management going to do to safeguard the workers at work under COVID19? I also understand this process will involve much higher percentages of ethanol than we usually deal with, and hydrogen peroxide. Will there be any safety issues? We don't currently have the capability to assess those issues. Statement from local Residents' Association The brewery site stands in the centre of our town, and on an important river. We would like to be sure there are no environmental or noise implications from the product change. Current staffing Current staffing consists of the following personnel: Role title Job description Chief Executive Overall company strategy Chief Financial Oversees all financial actions of the company officer (CFO) Factory manager Oversees internal factory activities. Reports to Chief Executive. Factory workers Operate process machinery, under factory manager Administration Processing of administrative tasks including Human resources, clerk correspondence (not finance). Reports to Chief Executive. Finance clerk Reports to, and supports, CFO Marketing, legal and other required services can be provided by external companies. No 1 1 1 5 1 1 All process equipment must be fully cleaned before use. Chemicals required: Parts per Litre Chemical (ml) 833.72 Ethanol (at least 96% pure) 41.72 Hydrogen peroxide 14.51 Emollient: glycerol (glycerine/glycerin) 98% 110.06 Sterile water Simple procedure Pour the alcohol into mixing receptacle Add hydrogen peroxide Add glycerol Add sterile distilled or cold boiled water. Mix products Bottle Store bottles for 72 hours before use to ensure any microbes that may have been present are destroyed. Note. Prevention of alcohol evaporation is extremely important. Sampling and testing should be conducted to test alcohol content meets NHS requirements, and to ensure there are no contaminants. Financial report The following data has been produced by the marketing and finance department. Please note some of the costs are estimated or provisional figures, and staffing is based on current staffing levels. The financial calculations can also be seen in the attached excel file. Units per sale 1000 Price per unit Cost production per unit 0.10 1.00 1 Year Sales Units sold Benefits 600 600,000 600,000 2 500 500,000 500,000 3 400 400,000 400,000 4 300 300,000 300,000 5 200 200,000 200,000 5,000 Costs Initial investment Fixed costs Variable costs total costs 359,000 60,000 419,000 359,000 50,000 409,000 359,000 40,000 399,000 359,000 30,000 389,000 359,000 20,000 379,000 5,000 E181,000 91,000 1,000 -89,000 -179,000 Net cash flow Discount rate Discount factors Discount net cash flow NPV IRR -5,000 11% 100% -5,000 97,350 -16% 89.00% 161,090 78.00% 70,980 67.00% 670 56.00% 49,840 45.00% 80,550 Initial investment is for tank alteration and minor changes to equipment and working environments Fixed costs are based on existing staff online Marks 5/100 5/100 20/100 10/100 Your Output You are being asked to provide a project plan including the following sections: Section Introduction Introduce the clients and project staff to the aim of the project, the reasons for the project, and the business climate. State any assumptions made. Project Scope What is and is not covered in this project plan. 2 page risk assessment From your reading and the stakeholder statement and questions, produce an assessment of the business, health & safety, environmental and other risks in relation to the product switch. Including likelihood and severity scores, and targeted project needs You may wish to address stakeholder questions References should be used Project Requirements Using your knowledge of requirements from the lecture produce a series of requirements to measure project success These may be related to project risk assessment, and to any specific legal and regulatory requirements for this product Governance A short section on the need for, and methods of, good governance. Breakdown structures Include a Project work breakdown structure & Organisation breakdown structure Schedule Produce a network diagram (including early and late dates) Identify the Critical path Costing and future costs/ value factors A costing document is provided below based on marketing and financial predictions. Describe the outlook of the project based on the document. Address projected sales, Net Present Value, and Internal Rate of Return Change Management A brief section saying how change is to be managed on the project in line with best practice Conclusions & Recommendations A brief section summarising the work in this report and stating any of your concerns, unanswered questions, or thoughts on the likely success of the project. References Presentation & Communication Total Page limit: 7 A4 pages maximum excluding references. Font: Arial 10 pt. 5/100 10/100 10/100 10/100 5/100 10/100 5/100 5/100 100/100 Units per sale Price per unit Cost production per unit 1000 1.00 0.10 Year Sales Units sold Benefits 600 600,000 600,000 2 500 500,000 500,000 3 400 400,000 400,000 4 300 300,000 300,000 5 200 200,000 200,000 5,000 Costs Initial investment Fixed costs Variable costs total costs 359,000 60,000 419.000 359,000 50,000 409,000 359,000 40,000 399,000 359,000 30,000 389,000 359,000 20,000 379,000 5,000 - 5,000 181,000 91,000 1,000 -89,000 -179,000 Net cash flow Discount rate Discount factors Discount net cash flow NPV IRR 89,00% 161,090 78.00% 70,980 67.00% 670 56.00% - 49,840 45.00% -80,550 100% -5,000 97,350 -16% Initial investment is for tank alteration and minor changes to equipment and working environments Fixed costs are based on existing staff online