Question: Engineering Problem 2: Quality Assurance & Quality Control CNG633 Process Control & Industrial Safety Cross-linked polyethylene (PEX) piping must be tested to ensure that it

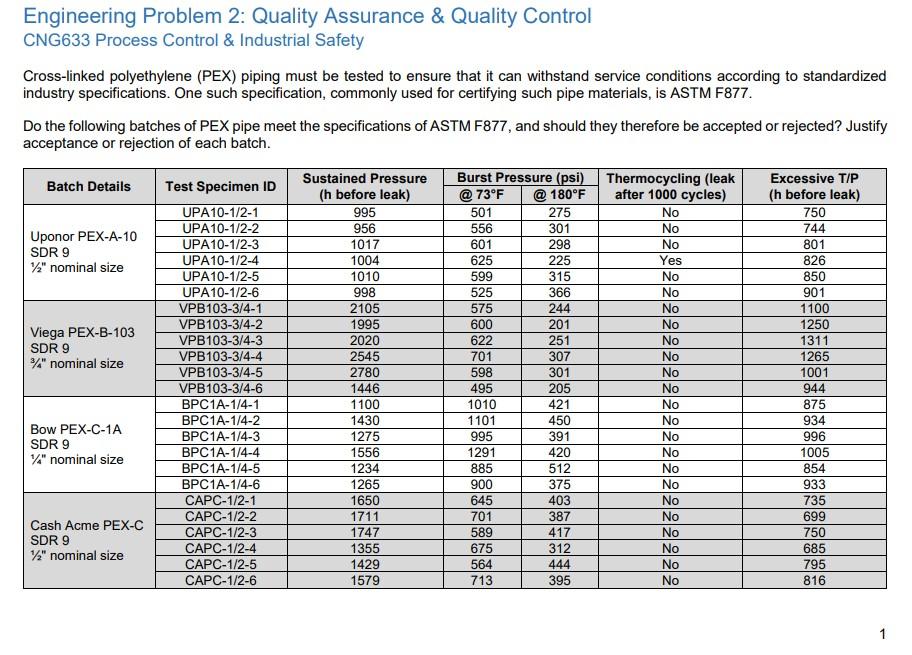

Engineering Problem 2: Quality Assurance & Quality Control CNG633 Process Control & Industrial Safety Cross-linked polyethylene (PEX) piping must be tested to ensure that it can withstand service conditions according to standardized industry specifications. One such specification, commonly used for certifying such pipe materials, is ASTM F877. Do the following batches of PEX pipe meet the specifications of ASTM F877, and should they therefore be accepted or rejected? Justify acceptance or rejection of each batch. Batch Details Uponor PEX-A-10 SDR 9 " nominal size Viega PEX-B-103 SDR 9 %" nominal size Test Specimen ID UPA10-1/2-1 UPA10-1/2-2 UPA10-1/2-3 UPA10-1/2-4 UPA10-1/2-5 UPA10-1/2-6 VPB103-3/4-1 VPB103-3/4-2 VPB103-3/4-3 VPB103-3/4-4 VPB103-3/4-5 VPB103-3/4-6 BPC1A-1/4-1 BPC1A-1/4-2 BPC1A-1/4-3 BPC1A-1/4-4 BPC1A-1/4-5 BPC1A-1/4-6 CAPC-1/2-1 CAPC-1/2-2 CAPC-1/2-3 CAPC-1/2-4 CAPC-1/2-5 CAPC-1/2-6 Sustained Pressure (h before leak) 995 956 1017 1004 1010 998 2105 1995 2020 2545 2780 1446 1100 1430 1275 1556 1234 1265 1650 1711 1747 1355 1429 1579 Burst Pressure (psi) @ 73F @ 180F 501 275 556 301 601 298 625 225 599 315 525 366 575 244 600 201 622 251 701 307 598 301 495 205 1010 421 1101 450 995 391 1291 420 885 512 900 375 645 701 387 589 417 675 312 564 444 713 395 Thermocycling (leak after 1000 cycles) No No No Yes No No No No No No No No No No No No No No No No No No No Excessive T/P (h before leak) 750 744 801 826 850 901 1100 1250 1311 1265 1001 944 875 934 996 1005 854 933 735 699 750 685 795 816 Bow PEX-C-1A SDR 9 " nominal size 403 Cash Acme PEX-C SDR 9 " nominal size No 1 Engineering Problem 2: Quality Assurance & Quality Control CNG633 Process Control & Industrial Safety Cross-linked polyethylene (PEX) piping must be tested to ensure that it can withstand service conditions according to standardized industry specifications. One such specification, commonly used for certifying such pipe materials, is ASTM F877. Do the following batches of PEX pipe meet the specifications of ASTM F877, and should they therefore be accepted or rejected? Justify acceptance or rejection of each batch. Batch Details Uponor PEX-A-10 SDR 9 " nominal size Viega PEX-B-103 SDR 9 %" nominal size Test Specimen ID UPA10-1/2-1 UPA10-1/2-2 UPA10-1/2-3 UPA10-1/2-4 UPA10-1/2-5 UPA10-1/2-6 VPB103-3/4-1 VPB103-3/4-2 VPB103-3/4-3 VPB103-3/4-4 VPB103-3/4-5 VPB103-3/4-6 BPC1A-1/4-1 BPC1A-1/4-2 BPC1A-1/4-3 BPC1A-1/4-4 BPC1A-1/4-5 BPC1A-1/4-6 CAPC-1/2-1 CAPC-1/2-2 CAPC-1/2-3 CAPC-1/2-4 CAPC-1/2-5 CAPC-1/2-6 Sustained Pressure (h before leak) 995 956 1017 1004 1010 998 2105 1995 2020 2545 2780 1446 1100 1430 1275 1556 1234 1265 1650 1711 1747 1355 1429 1579 Burst Pressure (psi) @ 73F @ 180F 501 275 556 301 601 298 625 225 599 315 525 366 575 244 600 201 622 251 701 307 598 301 495 205 1010 421 1101 450 995 391 1291 420 885 512 900 375 645 701 387 589 417 675 312 564 444 713 395 Thermocycling (leak after 1000 cycles) No No No Yes No No No No No No No No No No No No No No No No No No No Excessive T/P (h before leak) 750 744 801 826 850 901 1100 1250 1311 1265 1001 944 875 934 996 1005 854 933 735 699 750 685 795 816 Bow PEX-C-1A SDR 9 " nominal size 403 Cash Acme PEX-C SDR 9 " nominal size No 1

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts