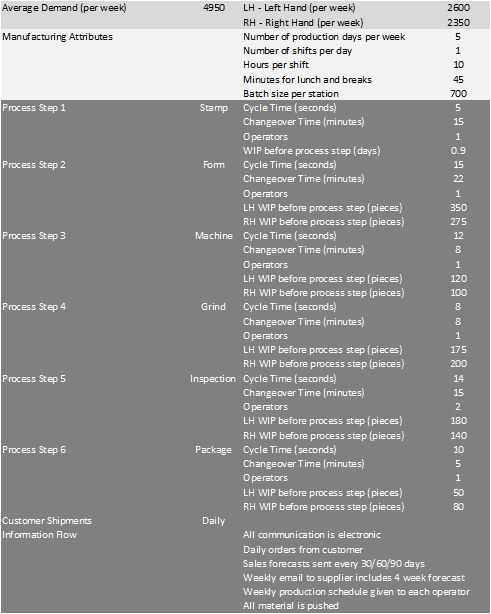

Question: Evaluation 1 Value Stream Mapping table [ [ Average Demand ( per week ) , 4 9 5 0 , LH - Left Hand

Evaluation Value Stream Mapping tableAverage Demand per weekLH Left Hand per weekRH Right Hand per weekManufacturing Attributes,,Number of production days per week,Number of shifts per day,Hours per shift,Minutes for lunch and breaks,Batch size per station,Process Step Stamp,Cycle Time secondsChangeover Time minutesOperators,WIP before process step daysProcess Step Form,Cycle Time secondsChangeover Time minutesOperators,LH WIP before process step piecesRH WP before process step piecesProcess Step Machine,Cycle Time secondsChangeover Time minutesOperators,LH WIP before process step piecesRH WIP before process step piecesProcess Step Grind,Cycle Time secondsChangeover Time minutesOperators,LH WIP before process step piecesRH WIP before process step piecesProcess Step Inspection,Cycle Time secondsChangeover Time minutesOperators,LH WIP before process step piecesRH WIP before process step piecesProcess Step Package,Cycle Time secondsChangeover Time minutesOperators,LH WIP before process step piecesRH WIP before process step piecesCustomer Shipments,Daily,,Information fow,,All communication is electronic,Daily orders from customer,Sales forecasts sent every daWeeky email to supplier includes wecastWeekdy production schedule given to eat,eratorAll material is pushed,

This is an individual assignment.

Conestoga Incorporated, a ball bearing manufacturing company located in Guelph, Ontario, Canada receives raw material sheets from Ontario Steel Company once a week every Monday for a product family of retainers casings in which ball bearings are held and then ships its finished product daily to a secondtier automotive manufacturing customer named Rockwood Enterprises.

The product family of the bearing manufacturing company under consideration consists of two types of retainersRight Hand RH and Left Hand LHthat are packaged for shipping in trays. The two types of retainers are identical mirror images of each other.

The manufacturing process consists of a cell containing a stamping operation, a forming cell, a machining cell, a grind cell, an inspection cell, and packaging operation after which the two types of retainers are shipped.

The information collected by the operations manager at Conestoga Inc. is shown in Table below.

Assignment consult the rubric for the evaluation criteria

Determine the takt time for this manufacturing cell

Create a Value Stream Map for Conestoga Inc

Determine the production lead time for this manufacturing cell

Determine the process Value Added Time VAT

Determine the Process Cycle Efficiency PCE for this manufacturing cell

Calculate the current manufacturing capacity units per day

Can Conestogas process meet customer demand? Explain.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock