Question: Example 1 : We produce two type end products: A and B . Also the sub - item C is sold as an end product.

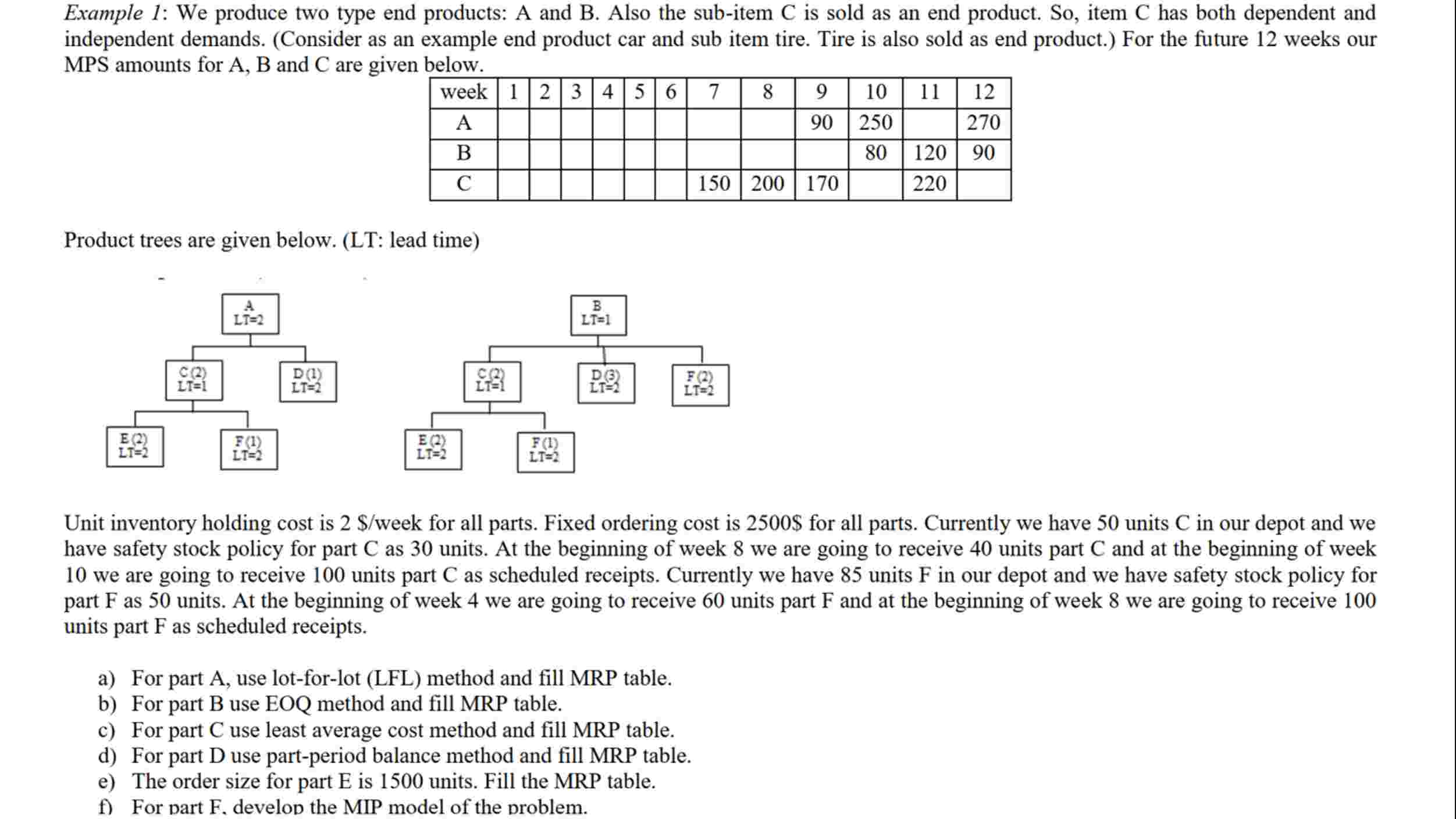

Example : We produce two type end products: A and B Also the subitem C is sold as an end product. So item C has both dependent and independent demands. Consider as an example end product car and sub item tire. Tire is also sold as end product. For the future weeks our MPS amounts for A B and C are given below. Product trees are given below. LT: lead time Unit inventory holding cost is $ week for all parts. Fixed ordering cost is $ for all parts. Currently we have units C in our depot and we have safety stock policy for part C as units. At the beginning of week we are going to receive units part C and at the beginning of week we are going to receive units part C as scheduled receipts. Currently we have units F in our depot and we have safety stock policy for part F as units. At the beginning of week we are going to receive units part F and at the beginning of week we are going to receive units part F as scheduled receipts. a For part A use lotforlot LFL method and fill MRP table. b For part B use EOQ method and fill MRP table. c For part C use least average cost method and fill MRP table. d For part D use partperiod balance method and fill MRP table. e The order size for part E is units. Fill the MRP table. f For part F develop the MIP model of the problem.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock