Question: Exercise #1 only please show the solution with the steps and excel module 1. Rxplain the basic trade-offs to consider when creotint trade-otts involve balaneing

Exercise #1 only

please show the solution with the steps and excel module

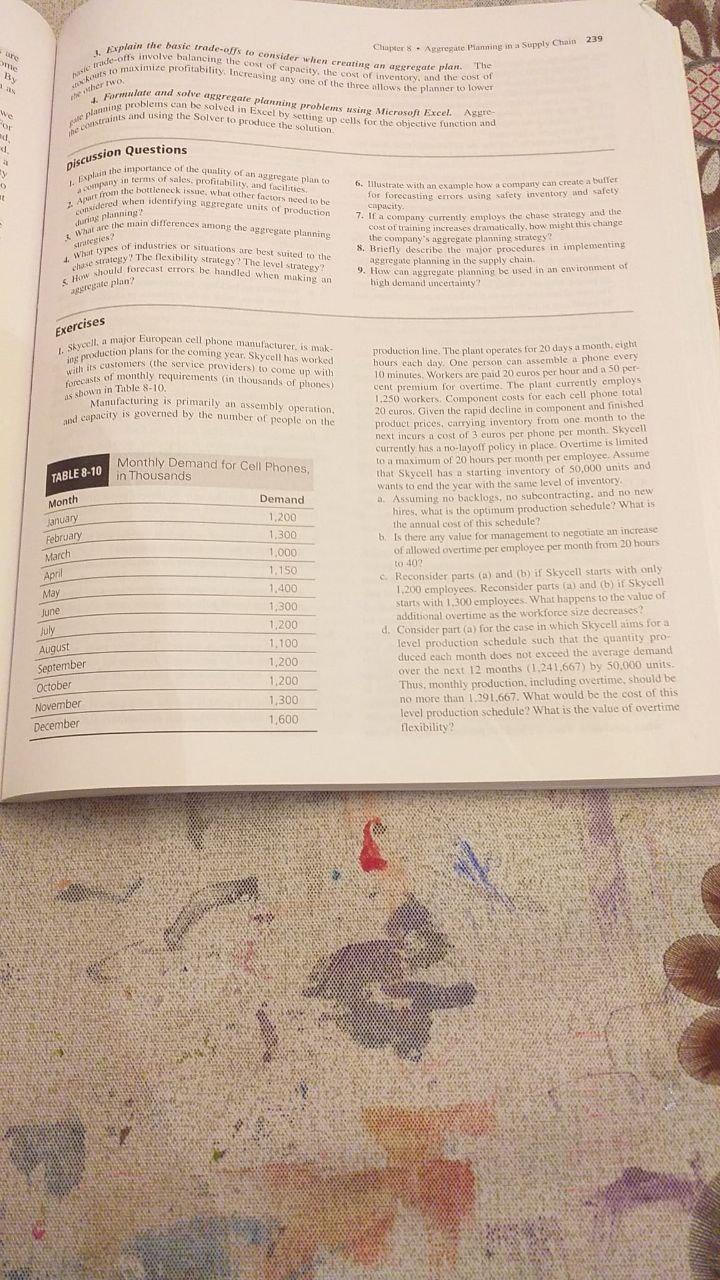

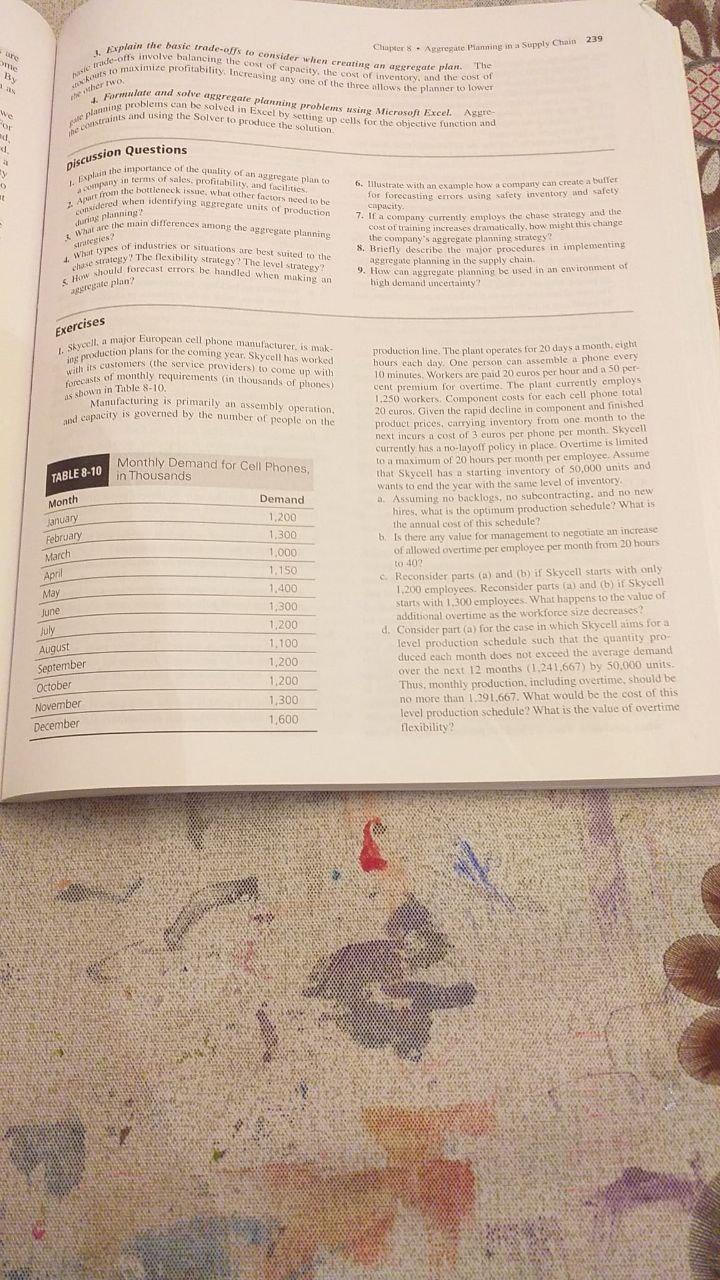

1. Rxplain the basic trade-offs to consider when creotint trade-otts involve balaneing the cost of capacity, the eoting an aggregate plan. The pouts to maximize protitabitity. Increasing any one of the est of inventory, and the cost of inter two. 4. Formulate and solve aggregate planning problems usimg Microsoft Excel. Aggreplaning problems can be solved in Excel by setting up cells for the objective function and peceolseraits and using the Solver to produce the solution. piscussion Questions 1. Explaia the imporance of the quality of an aggregate plan to acompany in terms of sales, profitability. and facilatics. 2. Apart from the bottieneck issue, what other factors need io be cathrulered when 7. If a company currently employs the chase straiegy and the griteries? cost of traming increases dramatically, how might thuschainge 4. Whit types of industries or situitions are best suited to the the company"s aggregare plamaing stratcgy? chase strategy? The flexibility strutegy? The level strategy? 8. Briefly describe the major procedures in implenenting 5. How whould foreenst errors be handled when making an agsicibate plan? 9. Hew can aggregate planning be used in an environmest of high demanit uncertainty? Exercises 1. Styedll. a major European cell phone manufacturer. is makins pooduction plans for the coming year. Skycell has worked . production line. The plant operates for 20 days a month, eight with its customers (the service providers) to come up with . hour cach day. One person can assemble a phone every forecusts of monthly requirements (in thousands of phones) us shown in Table 810. Manufacturing is primarily an assembly operation, 1.250 worker. Component costs for each cell phone fotal Namificturing is primarity an assembly operation, 20 curos. Given the rapid decline in component and finished product prices, carrying inventory from one month to the next incurs a cost of 3 euros per phone per month. Skyeell currently has a no-layoff policy in place Overime is limited to a maximum of 20 hour per month per employee. Assume that Skyeell has a starting inventory of 50,000 units and wants to end the year with the same level of inventory. a. Assuming no backlogs, no subcontracting, and no new hires, what is the optinum production sehedule? What is the annual cost of this schedule? b. Is there any value for management to negotiale an increase of allowed overtime per employee per month from 20 hours to 40 ? c. Reconsider parts (a) and (b) if Skyeell starts with only 1,200 employees. Reconsider parts (a) and (b) if Skyeell start with 1,300 employees. What happens to the value of additional overtime as the workforee size decreases? d. Consider part (a) for the case in which Skyeell aims for a level production schedule such that the quantity produced each month does not exceed the average demand over the next 12 moaths (1,241,667) by 50.000 units. Thus, monthly production, including overtime, should be no more than 1,391,667. What would be the cost of this level production schedule? What is the value of overtime. flexibility