Question: Exercise 9 - 3 3 ( Static ) Activity - Based Costing ( LO 9 - 4 , 5 ) After reviewing the new activity

Exercise Static ActivityBased Costing LO

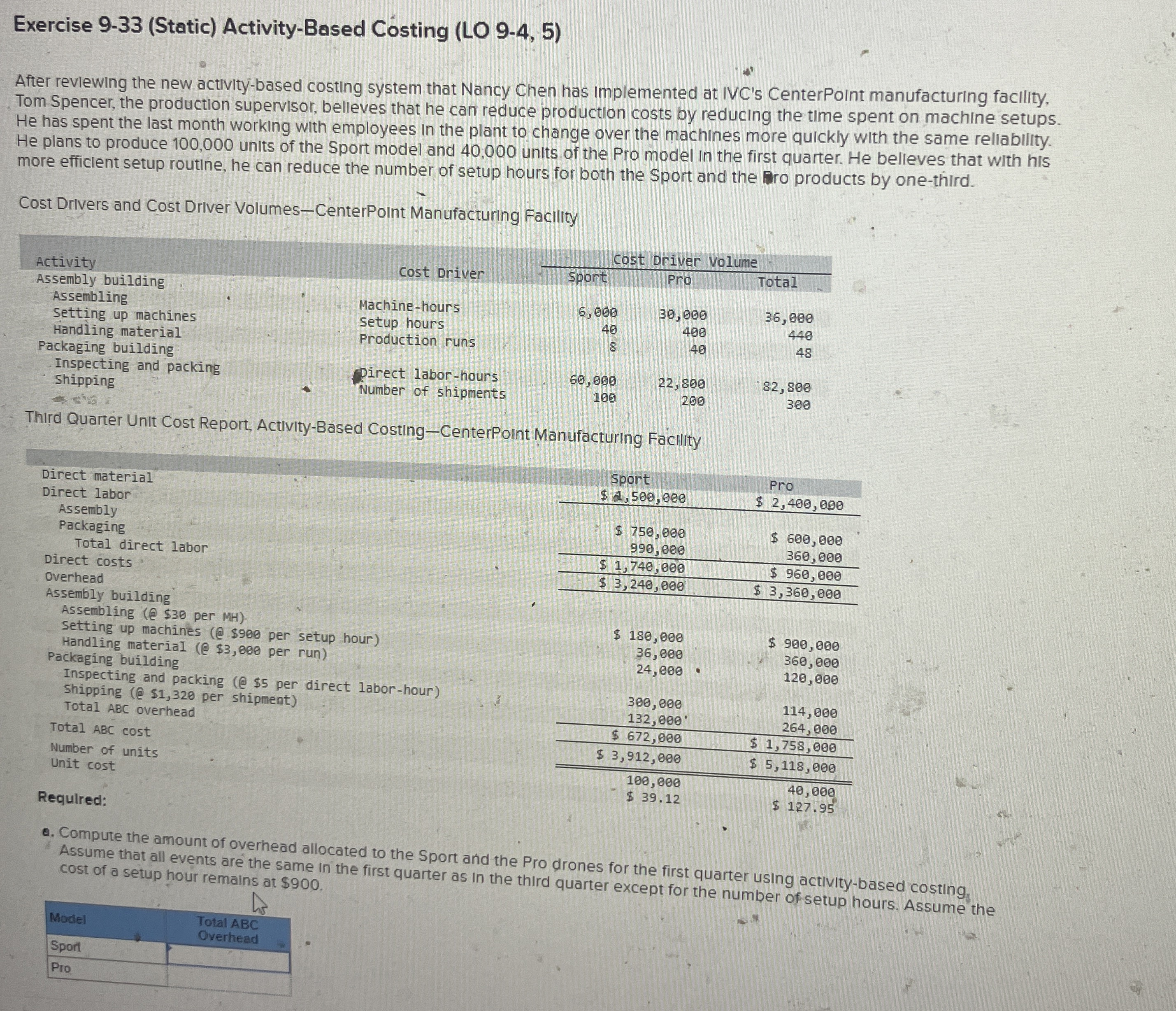

After reviewing the new activitybased costing system that Nancy Chen has implemented at IVC's CenterPoint manufacturing facility, Tom Spencer, the production supervisor, belleves that he can reduce production costs by reducing the time spent on machine setups. He has spent the last month working with employees in the plant to change over the machines more quickly with the same reliability. He plans to produce units of the Sport model and units of the Pro model In the first quarter. He belleves that with his more efficlent setup routine, he can reduce the number of setup hours for both the Sport and the fro products by onethird.

Cost Drivers and Cost Driver VolumesCenterPoint Manufacturing Facility

Third Quarter Unit Cost Report, ActivityBased CostingCenterPoint Manufacturing Facility

Assembling $ per MH

Setting up machines @$ per setup hour

Handling material @$ per run

Packaging building

Inspecting and packing @$ per direct laborhour

Shipping @ $ per shipment

Total ABC overhead

Total ABC cost

Number of units

Unit cost

table$$

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock