Question: explain each step in detail please. A distillation column is being designed to carry out a separation on a feed containing 25mol% CzHs, 38mol% nC.H10,

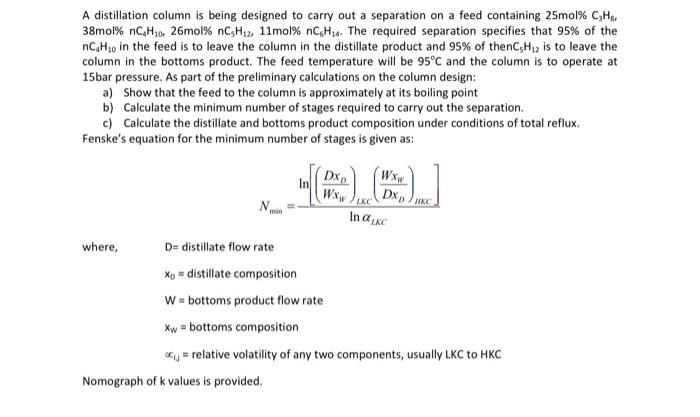

A distillation column is being designed to carry out a separation on a feed containing 25mol% CzHs, 38mol% nC.H10, 26mol% nCsH2 11mol% nC H14. The required separation specifies that 95% of the nC. Ho in the feed is to leave the column in the distillate product and 95% of thenC3H12 is to leave the column in the bottoms product. The feed temperature will be 95C and the column is to operate at 15bar pressure. As part of the preliminary calculations on the column design: a) Show that the feed to the column is approximately at its boiling point b) Calculate the minimum number of stages required to carry out the separation. c) Calculate the distillate and bottoms product composition under conditions of total reflux. Fenske's equation for the minimum number of stages is given as: DXD DXD WX In LKC HRC N where, DE distillate flow rate Xo = distillate composition W = bottoms product flow rate *w = bottoms composition v=relative volatility of any two components, usually LKC to HKC Nomograph of k values is provided

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts