Question: EXPLAIN HOW THE PROCESS THE TEAM FOLLOWED MIGHT ALIGN WITH DMAIC, THE DEMING CYCLE,AND THE CREATIVE PROBLEM SOLVING PROCESS . APPLYING QUALITY IMPROVEMENT TOOLS TO

EXPLAIN HOW THE PROCESS THE TEAM FOLLOWED MIGHT ALIGN WITH DMAIC, THE DEMING CYCLE,AND THE CREATIVE PROBLEM SOLVING PROCESS .

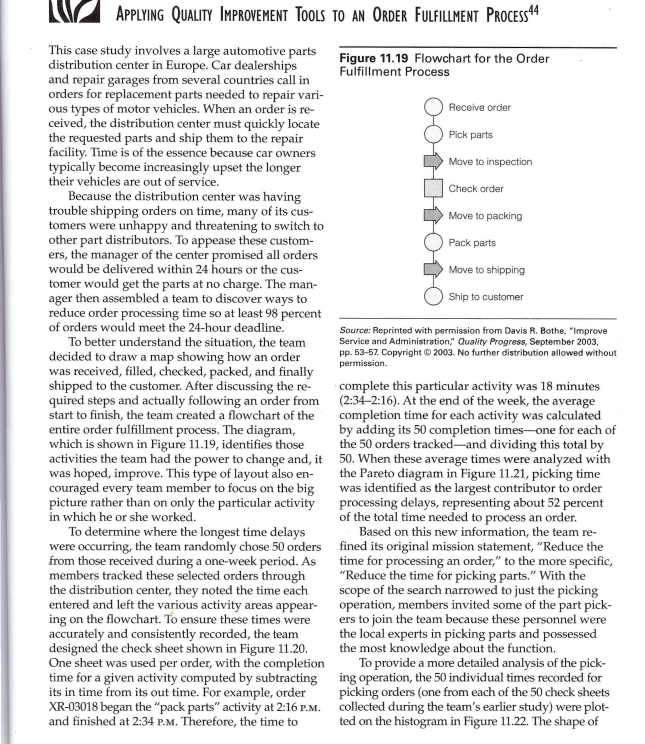

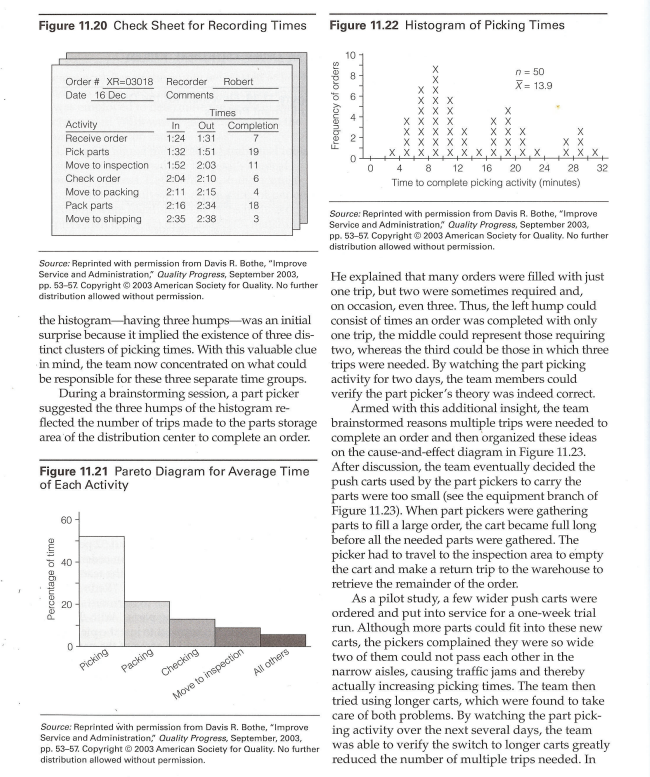

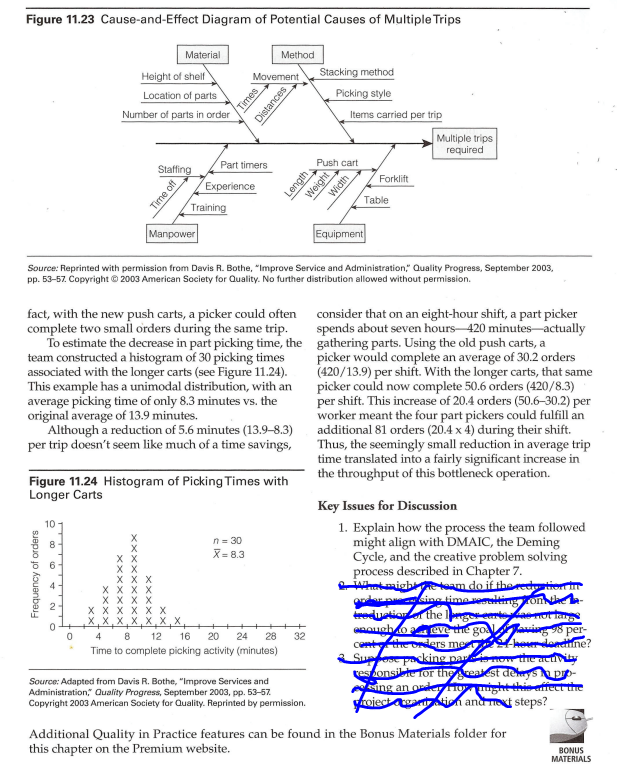

APPLYING QUALITY IMPROVEMENT TOOLS TO AN ORDER FULFILLMENT PROCESS44 Figure 11.19 Flowchart for the Order Fulfillment Process Receive order This case study involves a large automotive parts distribution center in Europe. Car dealerships and repair garages from several countries call in orders for replacement parts needed to repair vari- ous types of motor vehicles. When an order is re- ceived, the distribution center must quickly locate the requested parts and ship them to the repair facility. Time is of the essence because car owners typically become increasingly upset the longer their vehicles are out of service. Pick parts Move to inspection Check order Move to packing Pack parts Because the distribution center was having trouble shipping orders on time, many of its cus- tomers were unhappy and threatening to switch to other part distributors. To appease these custom- ers, the manager of the center promised all orders would be delivered within 24 hours or the cus- tomer would get the parts at no charge. The man- ager then assembled a team to discover ways to reduce order processing time so at least 98 percent of orders would meet the 24-hour deadline. Move to shipping Ship to customer Source: Reprinted with permission from Davis R. Bothe, "Improve Service and Administration," Quality Progress, September 2003, pp. 53-57. Copyright 2003. No further distribution allowed without permission. To better understand the situation, the team decided to draw a map showing how an order was received, filled, checked, packed, and finally shipped to the customer. After discussing the re- complete this particular activity was 18 minutes quired steps and actually following an order from (2:34-2:16). At the end of the week, the average start to finish, the team created a flowchart of the completion time for each activity was calculated entire order fulfillment process. The diagram, by adding its 50 completion times-one for each of which is shown in Figure 11.19, identifies those the 50 orders tracked-and dividing this total by activities the team had the power to change and, it 50. When these average times were analyzed with was hoped, improve. This type of layout also en- couraged every team member to focus on the big picture rather than on only the particular activity in which he or she worked. the Pareto diagram in Figure 11.21, picking time was identified as the largest contributor to order processing delays, representing about 52 percent of the total time needed to process an order. To determine where the longest time delays were occurring, the team randomly chose 50 orders from those received during a one-week period. As members tracked these selected orders through the distribution center, they noted the time each entered and left the various activity areas appear- ing on the flowchart. To ensure these times were accurately and consistently recorded, the team designed the check sheet shown in Figure 11.20. One sheet was used per order, with the completion time for a given activity computed by subtracting its in time from its out time. For example, order XR-03018 began the "pack parts" activity at 2:16 P.M. and finished at 2:34 P.M. Therefore, the time to Based on this new information, the team re- fined its original mission statement, "Reduce the time for processing an order," to the more specific, "Reduce the time for picking parts." With the scope of the search narrowed to just the picking operation, members invited some of the part pick- ers to join the team because these personnel were the local experts in picking parts and possessed the most knowledge about the function. To provide a more detailed analysis of the pick- ing operation, the 50 individual times recorded for picking orders (one from each of the 50 check sheets collected during the team's earlier study) were plot- ted on the histogram in Figure 11.22. The shape of Figure 11.20 Check Sheet for Recording Times Figure 11.22 Histogram of Picking Times Order # XR-03018 Recorder Robert Date 16 Dec n = 50 X= 13.9 Comments Times Activity Out Completion In 1:24 1:31 X X X X X X Receive order 7 X X X X X Pick parts 1:32 1:51 19 Move to inspection 1:52 2:03 11 4 Check order 8 12 16 20 24 28 Time to complete picking activity (minutes) 2:04 2:10 6 2:11 2:15 4 Move to packing Pack parts Move to shipping 18 2:16 2:34 2:35 2:38 3 Source: Reprinted with permission from Davis R. Bothe, "Improve Service and Administration, Quality Progress, September 2003, pp. 53-57. Copyright 2003 American Society for Quality. No further distribution allowed without permission. Source: Reprinted with permission from Davis R. Bothe, "Improve Service and Administration, Quality Progress, September 2003, pp. 53-57 Copyright 2003 American Society for Quality. No further distribution allowed without permission. the histogram-having three humps was an initial surprise because it implied the existence of three dis- tinct clusters of picking times. With this valuable clue in mind, the team now concentrated on what could be responsible for these three separate time groups. He explained that many orders were filled with just one trip, but two were sometimes required and, on occasion, even three. Thus, the left hump could consist of times an order was completed with only one trip, the middle could represent those requiring two, whereas the third could be those in which three trips were needed. By watching the part picking activity for two days, the team members could verify the part picker's theory was indeed correct. During a brainstorming session, a part picker suggested the three humps of the histogram re- flected the number of trips made to the parts storage area of the distribution center to complete an order. Figure 11.21 Pareto of Each Activity Diagram for Average Time Armed with this additional insight, the team brainstormed reasons multiple trips were needed to complete an order and then organized these ideas on the cause-and-effect diagram in Figure 11.23. After discussion, the team eventually decided the push carts used by the part pickers to carry the parts were too small (see the equipment branch of Figure 11.23). When part pickers were gathering parts to fill a large order, the cart became full long before all the needed parts were gathered. The picker had to travel to the inspection area to empty the cart and make a return trip to the warehouse to retrieve the remainder of the order. 60 40 As a pilot study, a few wider push carts were ordered and put into service for a one-week trial run. Although more parts could fit into these new carts, the pickers complained they were so wide two of them could not pass each other in the narrow aisles, causing traffic jams and thereby actually increasing picking times. The team then tried using longer carts, which were found to take care of both problems. By watching the part pick- ing activity over the next several days, the team Source: Reprinted with permission from Davis R. Bothe, "Improve Service and Administration, Quality Progress, September, 2003, pp. 53-57. Copyright 2003 American Society for Quality. No further was able to verify the switch to longer carts greatly reduced the number of multiple trips needed. In distribution allowed without permission. of time Percentage of t 20 Picking Packing Checking Move to inspection All others of orders Frequency 32 Figure 11.23 Cause-and-Effect Diagram of Potential Causes of Multiple Trips Material Method Height of shelf Movement Stacking method Location of parts Picking style Number of parts in order Items carried per trip Staffing Forklift Multiple trips required Training Manpower Equipment Source: Reprinted with permission from Davis R. Bothe, "Improve Service and Administration," Quality Progress, September 2003, pp. 53-57. Copyright 2003 American Society for Quality. No further distribution allowed without permission. fact, with the new push carts, a picker could often complete two small orders during the same trip. To estimate the decrease in part picking time, the team constructed a histogram of 30 picking times associated with the longer carts (see Figure 11.24). This example has a unimodal distribution, with an average picking time of only 8.3 minutes vs. the original average of 13.9 minutes. consider that on an eight-hour shift, a part picker spends about seven hours 420 minutes actually gathering parts. Using the old push carts, a picker would complete an average of 30.2 orders (420/13.9) per shift. With the longer carts, that same picker could now complete 50.6 orders (420/8.3) per shift. This increase of 20.4 orders (50.6-30.2) per worker meant the four part pickers could fulfill an additional 81 orders (20.4 x 4) during their shift. Thus, the seemingly small reduction in average trip time translated into a fairly significant increase in the throughput of this bottleneck operation. Although a reduction of 5.6 minutes (13.9-8.3) per trip doesn't seem like much of a time savings, Figure 11.24 Histogram of Picking Times with Longer Carts Key Issues for Discussion n = 30 X= 8.3 1. Explain how the process the team followed might align with DMAIC, the Deming Cycle, and the creative problem solving process described in Chapter 7. What might the team do if the rech X order pussing time resulting on the la reduction or the longeste enough to a eve the go cent of the orders meet Suppose packing pa as not farg Javing 98 per- ever donetine? 0 16 20 24 4 8 12 28 32 Time to complete picking activity (minutes) the responsible for the greatest delays 1 sing an order Source: Adapted from Davis R. Bothe, "Improve Services and Administration, Quality Progress, September 2003, pp. 53-57. Copyright 2003 American Society for Quality. Reprinted by permission. might this affect the project organation and next steps? Additional Quality in Practice features can be found in the Bonus Materials folder for this chapter on the Premium website. BONUS MATERIALS Frequency of orders Time off Times Distances Part timers Experience Length Push cart Weight Width TableStep by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts