Question: explain it Question 3 (50 Marks): Internal External 100 135 60 20 P1 10 P2 CI Customer 45 10 1) The input into P2 was

explain it

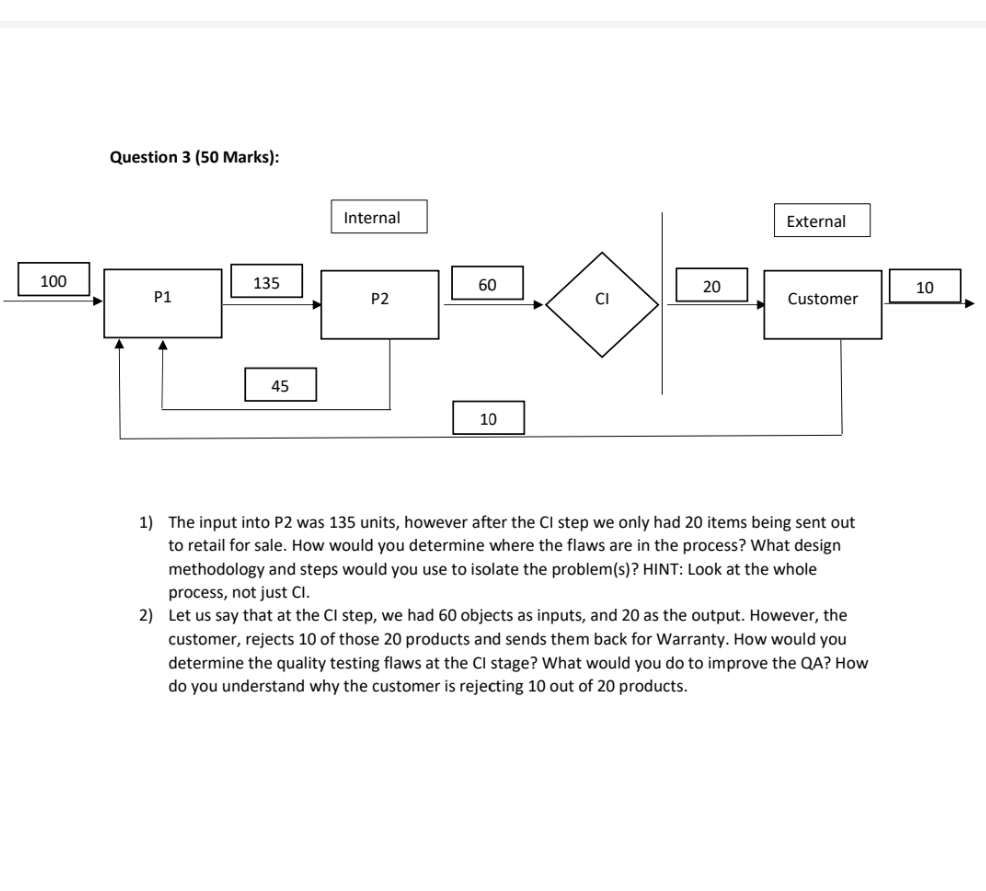

Question 3 (50 Marks): Internal External 100 135 60 20 P1 10 P2 CI Customer 45 10 1) The input into P2 was 135 units, however after the CI step we only had 20 items being sent out to retail for sale. How would you determine where the flaws are in the process? What design methodology and steps would you use to isolate the problem(s)? HINT: Look at the whole process, not just Cl. 2) Let us say that at the CI step, we had 60 objects as inputs, and 20 as the output. However, the customer, rejects 10 of those 20 products and sends them back for Warranty. How would you determine the quality testing flaws at the CI stage? What would you do to improve the QA? How do you understand why the customer is rejecting 10 out of 20 products

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts