Question: F 2 0 2 4 MGTS 3 5 2 ( CC 9 1 ) Case Assignment - Inventory Management ( 1 0 % ,

F MGTS CC Case Assignment Inventory Management Total points

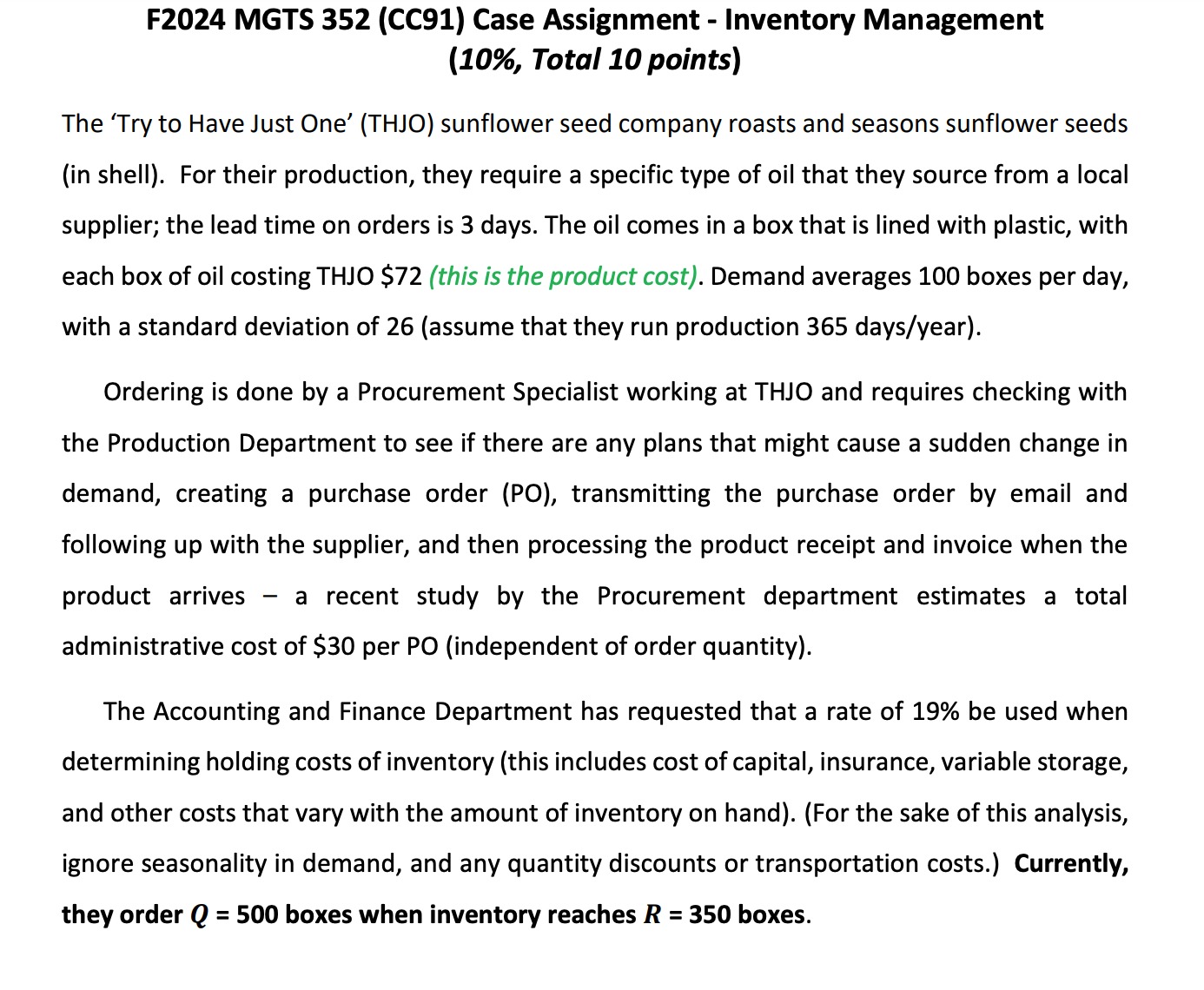

The 'Try to Have Just One' THJO sunflower seed company roasts and seasons sunflower seeds in shell For their production, they require a specific type of oil that they source from a local supplier; the lead time on orders is days. The oil comes in a box that is lined with plastic, with each box of oil costing THJO $ this is the product cost Demand averages boxes per day, with a standard deviation of assume that they run production daysyear

Ordering is done by a Procurement Specialist working at THJO and requires checking with the Production Department to see if there are any plans that might cause a sudden change in demand, creating a purchase order PO transmitting the purchase order by email and following up with the supplier, and then processing the product receipt and invoice when the product arrives a recent study by the Procurement department estimates a total administrative cost of $ per PO independent of order quantity

The Accounting and Finance Department has requested that a rate of be used when determining holding costs of inventory this includes cost of capital, insurance, variable storage, and other costs that vary with the amount of inventory on handFor the sake of this analysis, ignore seasonality in demand, and any quantity discounts or transportation costs. Currently, they order Q boxes when inventory reaches R boxes. points Diagram their current ordering policy in a "sawtooth" diagram that clearly labels the order quantity, reorder point, cycle stock, average cycle stock, safety stock and lead time. Start time zero with units on hand so your first order will be placed at day Hint Cycle Stock is a changing variable while Average Cycle Stock is a constant. They are two different concepts.

NOTE Equations and calculations are tangible ways to implement a concept, but the concept is important as well be sure to understand what you are doing and why, and not just how to make the calculation when completing this assignment.

Inventory

Time Days points Find the annual ordering and holding costs associated with the current ordering policy Qmathbf boxes Then determine the optimal order quantity to minimize total annual ordering plus holding costs. Note it will be necessary to use annual demand to do this.

points Finally, what is the cycle service level CSL if the reorder point is boxes? What is the reorder point required to ensure a cycle service level?

Cycle service level CSLwhen R boxes:

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock