Question: Figure 2 shows an open flat belt drive connected to a motor and a pulley. The motor transmits 20 kW to the connect pulley

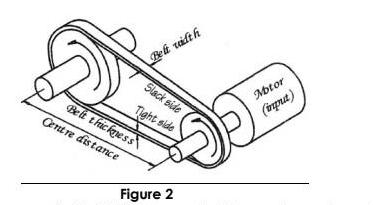

Figure 2 shows an open flat belt drive connected to a motor and a pulley. The motor transmits 20 kW to the connect pulley of 450 mm diameter and is rotating at 850 r/min to a second pulley rotating at 400 r/min. The distance between pulley centres is approximately 2 m. The belt is 6 mm thick and has a density of 970 kg/m. The maximum stress in the belt is not to exceed 2,7 MPa. The coefficient of friction for both pulleys is 0,3. Determine: 2.1. The diameter of the second pulley. 2.2. The length of the belt. 3.3. The width of the belt taking centrifugal tension into account. 3.1. Describe 5 shafts couplings 3.2. Two shafts, each 76 mm in diameter, are to be connected by a flange coupling; the diameter of the bolt circle is 128 mm. 3.2.1. If the Stress in the shaft is 69 MPa and in the bolts 62 MPa. Find the diameter and number of bolts required. 4.1. The student is required to identify any existing engineering PROBLEM of his/her choice, and the student is to follow the engineering design process listed below to solve the identified problem. Note: no calculations needed, do not choose load shedding as a problem. 4.1.1. Identification of a relevant problem Belt width Belt thickness Centre distance Slack side Tight side Figure 2 Motor (input)

Step by Step Solution

3.46 Rating (149 Votes )

There are 3 Steps involved in it

21 To determine the diameter of the second pulley we can use the speed ratio between the two pulleys ... View full answer

Get step-by-step solutions from verified subject matter experts