Question: First complete phase I then complete phase 2 please This is a transshipment problem 1. Distribution Network Design Project Background Panorama, Inc. is a third-party

First complete phase I then complete phase 2 please

This is a transshipment problem

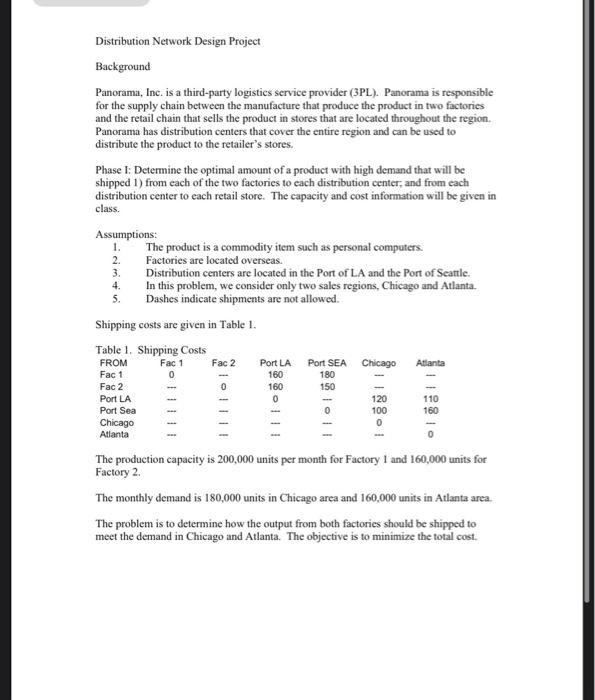

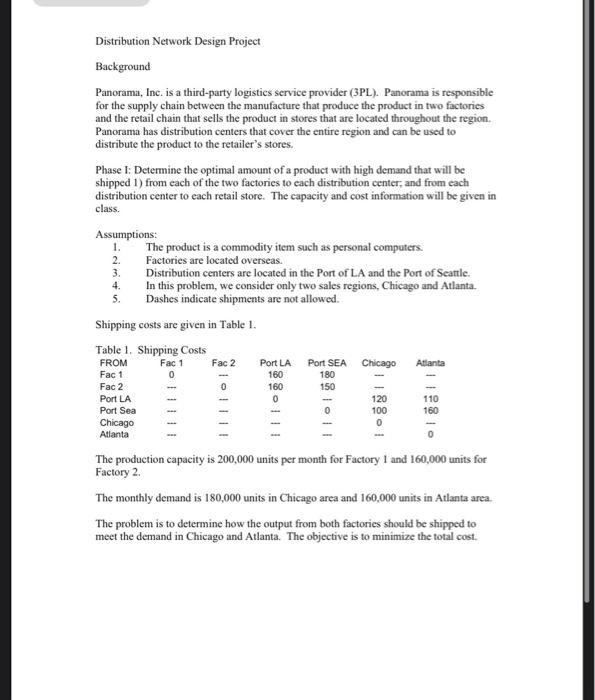

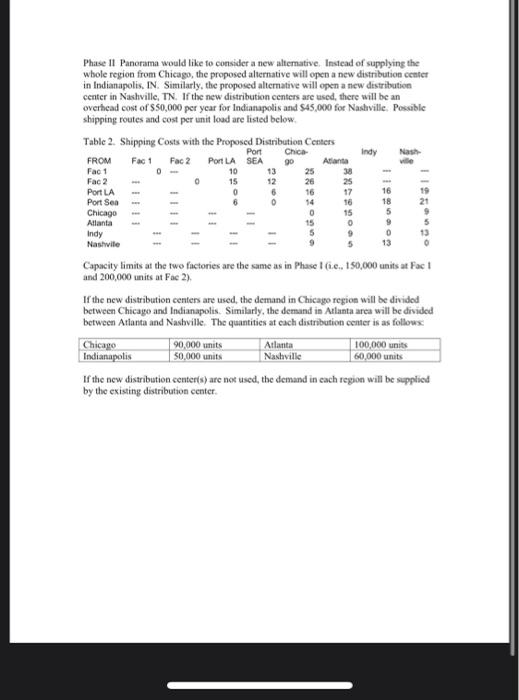

1. Distribution Network Design Project Background Panorama, Inc. is a third-party logistics service provider (3PL). Panorama is responsible for the supply chain between the manufacture that produce the product in two factories and the retail chain that sells the product in stores that are located throughout the region. Panorama has distribution centers that cover the entire region and can be used to distribute the product to the retailer's stores. Phase 1: Determine the optimal amount of a product with high demand that will be shipped 1) from each of the two factories to each distribution center, and from each distribution center to each retail store. The capacity and cost information will be given in class. Assumptions: The product is a commodity item such as personal computers. 2. Factories are located overseas. 3. Distribution centers are located in the Port of LA and the Port of Seattle. In this problem, we consider only two sales regions, Chicago and Atlanta. 5. Dashes indicate shipments are not allowed. Shipping costs are given in Table 1 Table 1. Shipping Costs FROM Fac 1 Fac 2 Port LA Port SEA Chicago Fac 1 Fac 2 160 150 Port LA 120 110 Port Sea 0 100 160 Chicago 0 Atlanta The production capacity is 200,000 units per month for Factory I and 160,000 units for Factory 2. The monthly demand is 180,000 units in Chicago area and 160,000 units in Atlanta area. The problem is to determine how the output from both factories should be shipped to meet the demand in Chicago and Atlanta. The objective is to minimize the total cost. Atlanta 0 160 180 0 0 0 Nas Fact 13 12 25 26 10 15 0 6 19 25 17 56 15 0 16 18 5 0 15 Phase Il Panorama would like to consider a new alternative. Instead of supplying the whole region from Chicago, the proposed alternative will open a new distribution center in Indianapolis, IN. Similarly, the proposed alternative will open a new distribution center in Nashville, TN. If the new distribution centers are used, there will be an overhead cost of $50,000 per year for Indianapolis and 545,000 for Nashville. Possible shipping routes and cost per unit load are listed below Table 2. Shipping Costs with the Proposed Distribution Centers Port Chic Indy FROM Fac 2 Port LA SEA 90 Atlanta Fac 1 38 Fac 2 Port LA 6 16 Port Sea Chicago Atlanta 9 Indy 13 Nashvile 13 0 Capacity limits at the two factories are the same as in Phase 1 6... 150,000 units at Fac ! and 200,000 units at Fac 2) If the new distribution centers are used the demand in Chicago region will be divided between Chicago and Indianapolis. Similarly, the demand in Atlanta area will be divided between Atlanta and Nashville, The quantities at each distribution center is as follows Chicago 90,000 units Atlanta 100,000 units Indianapolis 50,000 units Nashville 60,000 units If the new distribution center(s) are not used the demand in each region will be supplied by the existing distribution center 0

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock