Question: for $ 8 2 . 5 0 , and ToddleTotes for $ 6 6 . As a matter of policy, it wants to no less

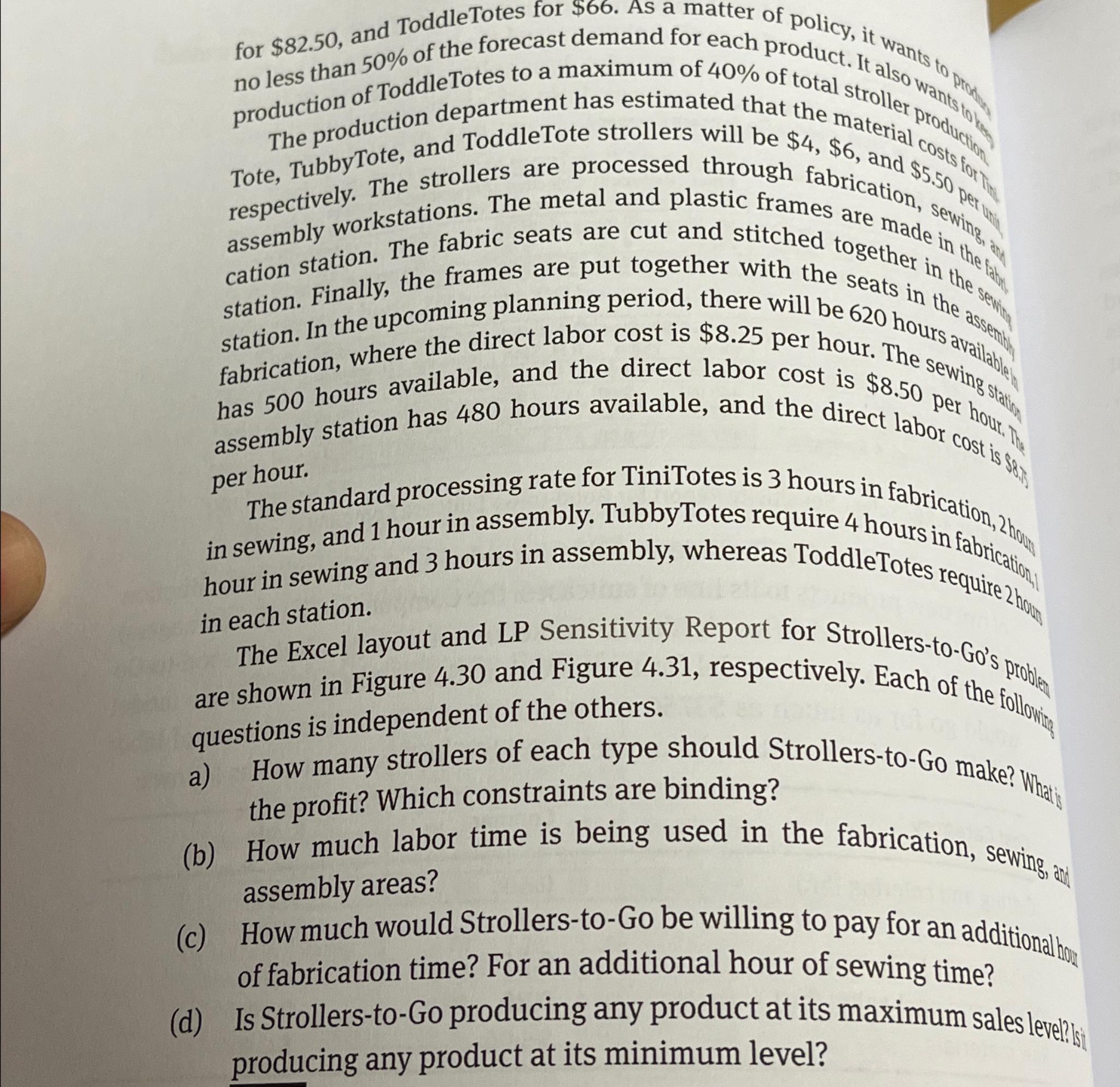

for $ and ToddleTotes for $ As a matter of policy, it wants to no less than of the forecast demand for each product. It also production of ToddleTotes to a maximum of of total stroller Tote, TubbyTote, and ToddleTote strollers will be $$ and $ for respectively. The strollers are processed through fabrication, sewing, assembly workstations. The metal and plastic frames are made in the fatic seats are cut and stitched together in the station. Finally, the frames are put together with the seats in the sem station. In the upcoming planning period, there will be hours avation the direct labor cost is $ per hour. The sewing has hours available, and the direct labor cost is $ per stat of assembly station has hours available, and the direct labor cost is per hour.

The standard processing rate for TiniTotes is hours in fabrication, in sewing, and hour in assembly. TubbyTotes require hours in fabrication, hour in sewing and hours in assembly, whereas ToddleTotes require in each station.

The Excel layout and LP Sensitivity Report for StrollerstoGo's problen are shown in Figure and Figure respectively. Each of the following questions is independent of the others.

a How many strollers of each type should StrollerstoGo make? What if the profit? Which constraints are binding?

b How much labor time is being used in the fabrication, sewing, and assembly areas?

c How much would StrollerstoGo be willing to pay for an additional hom of fabrication time? For an additional hour of sewing time?

d Is StrollerstoGo producing any product at its maximum sales level? sil producing any product at its minimum level?

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock