Question: for 9.1-4, the problem continues on the left top. Also, only do parts a), c), and d). erations Rese: x C Introduction To Operations Resex

for 9.1-4, the problem continues on the left top. Also, only do parts a), c), and d).

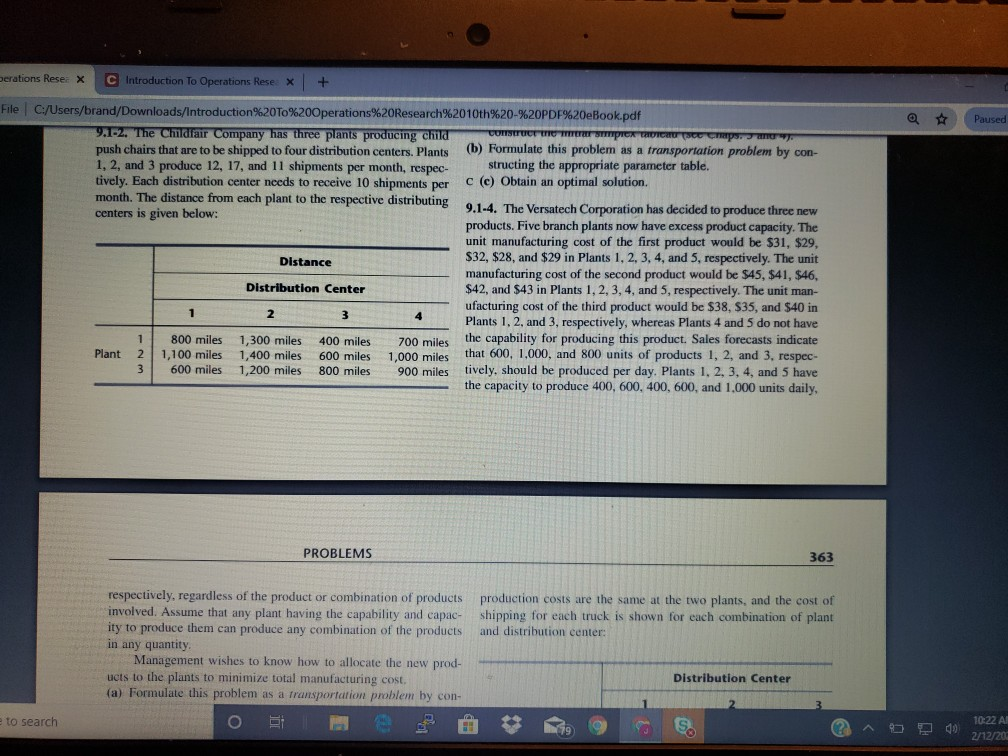

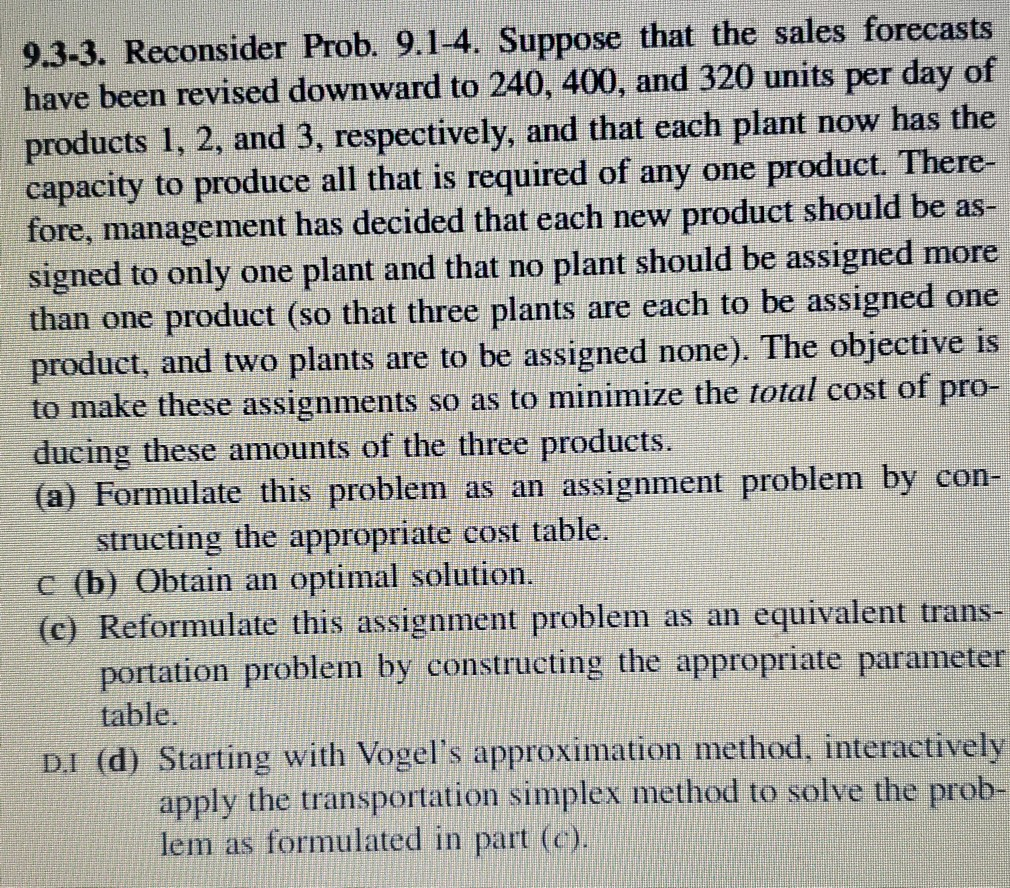

erations Rese: x C Introduction To Operations Resex + File a Paused C/Users/brand/Downloads/Introduction%20to%20Operations%20Research%2010th%20-%20PDP%20eBook.pdf 102. The Childar Company has three plants producing child COSTUTTU TITRE SPION TRIOTORTOR push chairs that are to be shipped to four distribution centers. Plants (b) Formulate this problem as a transportation problem by con- 1, 2, and 3 produce 12, 17, and 11 shipments per month, respec structing the appropriate parameter table. tively. Each distribution center needs to receive 10 shipments per C (C) Obtain an optimal solution. month. The distance from each plant to the respective distributing 9.1-4. The Versatech Corporation has decided to produce three new centers is given below: products. Five branch plants now have excess product capacity. The unit manufacturing cost of the first product would be $31, $29, Distance $32, $28, and $29 in Plants 1, 2, 3, 4, and 5, respectively. The unit manufacturing cost of the second product would be $45, $41, $46, Distribution Center $42, and $43 in Plants 1, 2, 3, 4, and 5, respectively. The unit man- ufacturing cost of the third product would be $38, S35, and S40 in Plants 1, 2, and 3, respectively, whereas Plants 4 and 5 do not have 800 miles 1,300 miles 400 miles 700 miles the capability for producing this product. Sales forecasts indicate Plant 2 1,100 miles 1,400 miles 600 miles 1,000 miles that 600, 1.000, and 800 units of products 1, 2, and 3. respec 3 600 miles 1,200 miles 800 miles 900 miles tively, should be produced per day. Plants 1. 2. 3. 4, and 5 have the capacity to produce 400, 600, 400, 600, and 1,000 units daily. 11 PROBLEMS 363 production costs are the same at the two plants, and the cost of shipping for each truck is shown for each combination of plant and distribution center: respectively, regardless of the product or combination of products involved. Assume that any plant having the capability and capac ity to produce them can produce any combination of the products in any quantity, Management wishes to know how to allocate the new prod- ucts to the plants to minimize total manufacturing cost. (a) Formulate this problem as a transportation problem by con- Distribution Center to search @ ^ 120122 9.3-3. Reconsider Prob. 9.1-4. Suppose that the sales forecasts have been revised downward to 240, 400, and 320 units per day of products 1, 2, and 3, respectively, and that each plant now has the capacity to produce all that is required of any one product. There- fore, management has decided that each new product should be as- signed to only one plant and that no plant should be assigned more than one product (so that three plants are each to be assigned one product, and two plants are to be assigned none). The objective is to make these assignments so as to minimize the total cost of pro- ducing these amounts of the three products. (a) Formulate this problem as an assignment problem by con- structing the appropriate cost table. C (b) Obtain an optimal solution. (c) Reformulate this assignment problem as an equivalent trans- portation problem by constructing the appropriate parameter table. DI (d) Starting with Vogel's approximation method, interactively apply the transportation simplex method to solve the prob- lem as formulated in part (c). erations Rese: x C Introduction To Operations Resex + File a Paused C/Users/brand/Downloads/Introduction%20to%20Operations%20Research%2010th%20-%20PDP%20eBook.pdf 102. The Childar Company has three plants producing child COSTUTTU TITRE SPION TRIOTORTOR push chairs that are to be shipped to four distribution centers. Plants (b) Formulate this problem as a transportation problem by con- 1, 2, and 3 produce 12, 17, and 11 shipments per month, respec structing the appropriate parameter table. tively. Each distribution center needs to receive 10 shipments per C (C) Obtain an optimal solution. month. The distance from each plant to the respective distributing 9.1-4. The Versatech Corporation has decided to produce three new centers is given below: products. Five branch plants now have excess product capacity. The unit manufacturing cost of the first product would be $31, $29, Distance $32, $28, and $29 in Plants 1, 2, 3, 4, and 5, respectively. The unit manufacturing cost of the second product would be $45, $41, $46, Distribution Center $42, and $43 in Plants 1, 2, 3, 4, and 5, respectively. The unit man- ufacturing cost of the third product would be $38, S35, and S40 in Plants 1, 2, and 3, respectively, whereas Plants 4 and 5 do not have 800 miles 1,300 miles 400 miles 700 miles the capability for producing this product. Sales forecasts indicate Plant 2 1,100 miles 1,400 miles 600 miles 1,000 miles that 600, 1.000, and 800 units of products 1, 2, and 3. respec 3 600 miles 1,200 miles 800 miles 900 miles tively, should be produced per day. Plants 1. 2. 3. 4, and 5 have the capacity to produce 400, 600, 400, 600, and 1,000 units daily. 11 PROBLEMS 363 production costs are the same at the two plants, and the cost of shipping for each truck is shown for each combination of plant and distribution center: respectively, regardless of the product or combination of products involved. Assume that any plant having the capability and capac ity to produce them can produce any combination of the products in any quantity, Management wishes to know how to allocate the new prod- ucts to the plants to minimize total manufacturing cost. (a) Formulate this problem as a transportation problem by con- Distribution Center to search @ ^ 120122 9.3-3. Reconsider Prob. 9.1-4. Suppose that the sales forecasts have been revised downward to 240, 400, and 320 units per day of products 1, 2, and 3, respectively, and that each plant now has the capacity to produce all that is required of any one product. There- fore, management has decided that each new product should be as- signed to only one plant and that no plant should be assigned more than one product (so that three plants are each to be assigned one product, and two plants are to be assigned none). The objective is to make these assignments so as to minimize the total cost of pro- ducing these amounts of the three products. (a) Formulate this problem as an assignment problem by con- structing the appropriate cost table. C (b) Obtain an optimal solution. (c) Reformulate this assignment problem as an equivalent trans- portation problem by constructing the appropriate parameter table. DI (d) Starting with Vogel's approximation method, interactively apply the transportation simplex method to solve the prob- lem as formulated in part (c)

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock