Question: For a small job shop, there are two alternative technologies: A and B. Technology-related information: Machine costs are as follows: Machine type Annualized acquisition cost

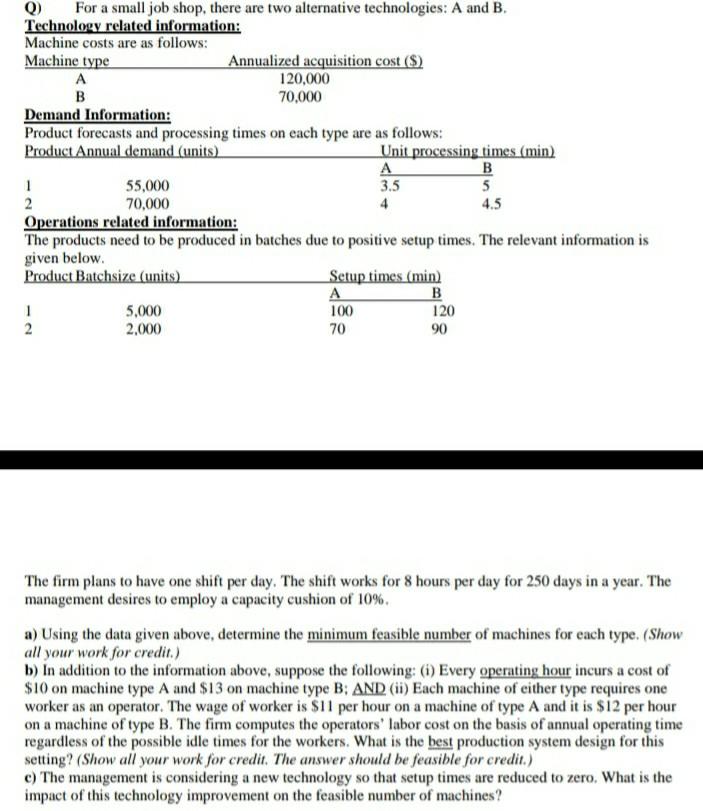

For a small job shop, there are two alternative technologies: A and B. Technology-related information: Machine costs are as follows: Machine type Annualized acquisition cost ($) A 120,000 B 70,000 Demand Information: Product forecasts and processing times for each type are as follows: Product Annual demand (units) Unit processing times (min) A B 1 55,000 3.5 5 2 70,000 4 4.5 Operations related information: The products need to be produced in batches due to positive setup times. The relevant information is given below. ProductBatchsize (units) Setup times (min) A B 1 5,000 100 120 2 2,000 70 90

The firm plans to have one shift per day. The shift works for 8 hours per day for 250 days in a year. The management desires to employ a capacity cushion of 10%. a) Using the data given above, determine the minimum feasible number of machines for each type. (Show all your work for credit.) b) In addition to the information above, suppose the following: (i) Every operating hour incurs a cost of $10 on machine type A and $13 on machine type B; AND (ii) Each machine of either type requires one worker as an operator. The wage of workers is $11 per hour on a machine of type A and it is $12 per hour on a machine of type B. The firm computes the operators labor cost on the basis of annual operating time regardless of the possible idle times for the workers. What is the best production system design for this setting? (Show all your work for credit. The answer should be feasible for credit.) c) The management is considering a new technology so that setup times are reduced to zero. What is the impact of this technology improvement on the feasible number of machines?

Q For a small job shop, there are two alternative technologies: A and B. Technology related information: Machine costs are as follows: Machine type Annualized acquisition cost ($) A 120,000 B 70,000 Demand Information: Product forecasts and processing times on each type are as follows: Product Annual demand (units) Unit processing times (min) B 1 55,000 3.5 5 2 70,000 4.5 Operations related information: The products need to be produced in batches due to positive setup times. The relevant information is given below. Product Batchsize (units) Setup times (min) B 1 5,000 100 120 2 2,000 70 90 The firm plans to have one shift per day. The shift works for 8 hours per day for 250 days in a year. The management desires to employ a capacity cushion of 10% a) Using the data given above, determine the minimum feasible number of machines for each type. (Show all your work for credit.) b) In addition to the information above, suppose the following: (1) Every operating hour incurs a cost of $10 on machine type A and $13 on machine type B: AND (ii) Each machine of either type requires one worker as an operator. The wage of worker is $11 per hour on a machine of type A and it is $12 per hour on a machine of type B. The firm computes the operators' labor cost on the basis of annual operating time regardless of the possible idle times for the workers. What is the best production system design for this setting? (Show all your work for credit. The answer should be feasible for credit.) c) The management is considering a new technology so that setup times are reduced to zero. What is the impact of this technology improvement on the feasible number of machines

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts