Question: for part 1, also tried 220,800 and it was wrong so please provide correct answer Reorder Point Morrison Manufacturing produces casings for sewing machines: large

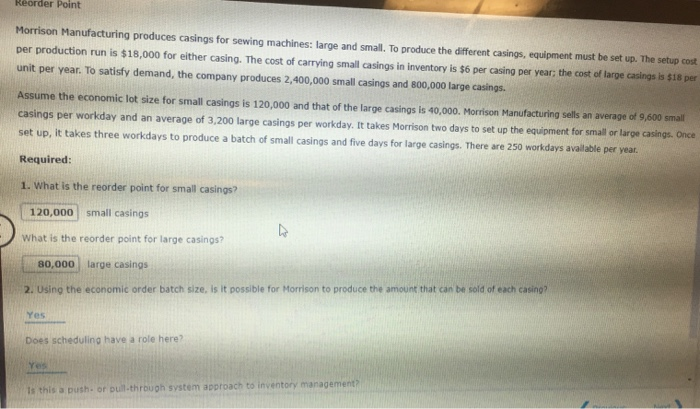

Reorder Point Morrison Manufacturing produces casings for sewing machines: large and small. To produce the different casings, equipment must be set up. The setup cost per production run is $18,000 for either casing. The cost of carrying small casings in inventory is $6 per casing per year; the cost of large casings is $18 per unit per year. To satisfy demand, the company produces 2,400,000 small casings and 800,000 large casings. Assume the economic lot size for small casings is 120,000 and that of the large casings is 40,000. Morrison Manufacturing sells an average of 9,600 small casings per workday and an average of 3,200 large casings per workday. It takes Morrison two days to set up the equipment for small or large casings. Once set up, it takes three workdays to produce a batch of small casings and five days for large casings. There are 250 workdays available per year Required: 1. What is the reorder point for small casings? 120,000 small casings What is the reorder point for large casings? 80,000 large casings 2. Usino the economic order batch size, is it possible for Morrison to produce the amount that can be sold of each casing? Yes Does scheduling have a role here? Yes Is this a push- or pull-through system approach to inventory management

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts