Question: For phi 2 0 mm D ( 7 ) / ( h ) 6 hole shaft combination: a . Calculate the limits of sizes

For phi mm Dh hole shaft combination:

a Calculate the limits of sizes and identify the fit.

b Explain Taylor's principle of gaging. Plug gages Go and Nogo are required to control

the production of phi mm D hole as per IS specification. The tolerances required in

the gage and additional wear tolerances are shown in Table Will you provide wear

tolerance on both go and nogo gages or on the one which wears more? Which gage is

expected to wear more and why? Find suitable dimensions of plug and ring go and no

go gages for both hole and shaft.

Given: Fundamental deviation of D hole, EIDITi; and h shaft, es ITi

Diameter range is mm Fundamental tolerance unit irootDD

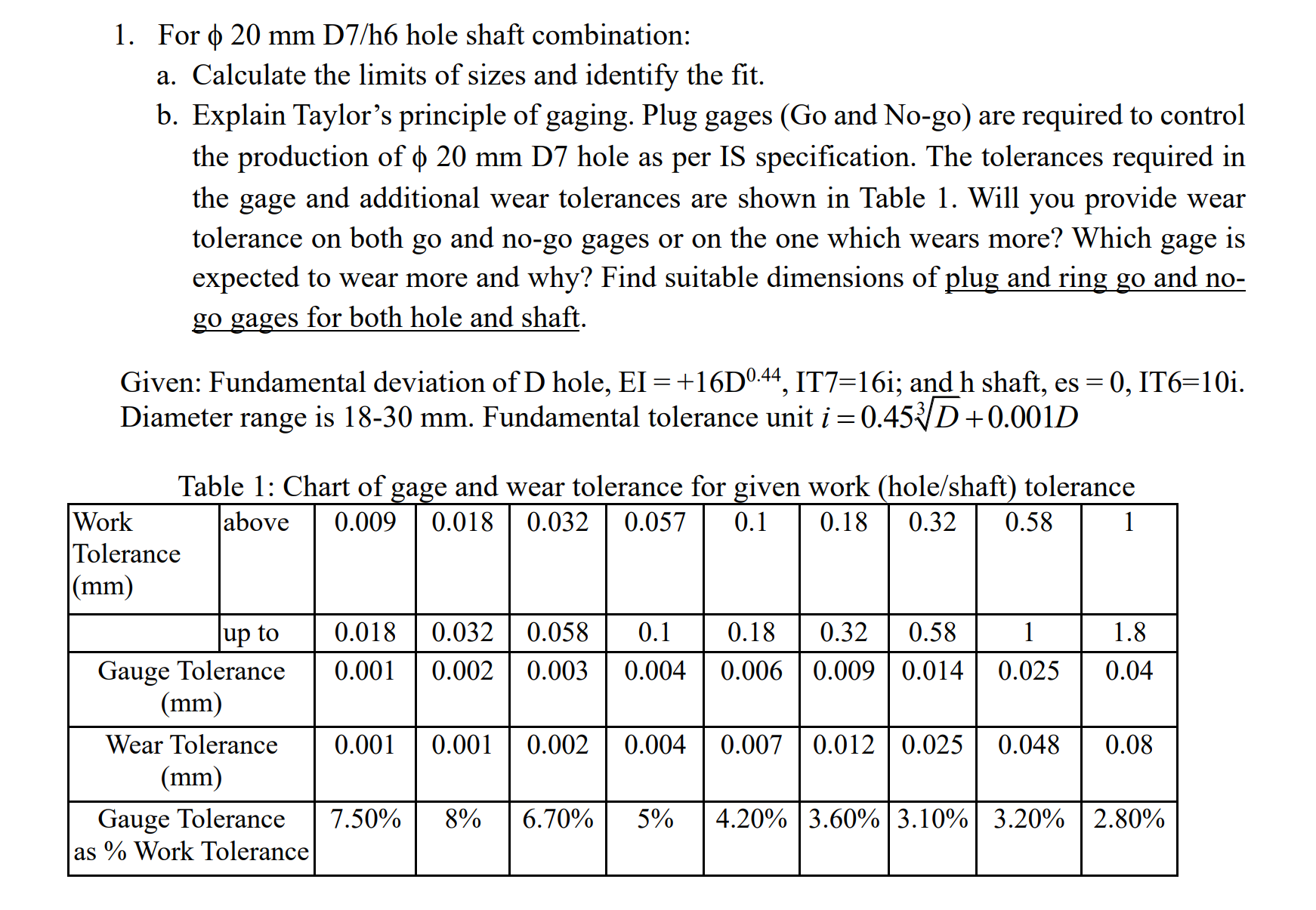

Table : Chart of gage and wear tolerance for given work holeshaft tolerance

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock