Question: * **For PP 63 PLEASE WILL YOU HELP ME WITH THE QUESTIONS I GOT WRONG IN RED. THANK YOU. PLEASE ANSWER ALL :) PP.51 A

***For PP 63 PLEASE WILL YOU HELP ME WITH THE QUESTIONS I GOT WRONG IN RED. THANK YOU.

PLEASE ANSWER ALL :)

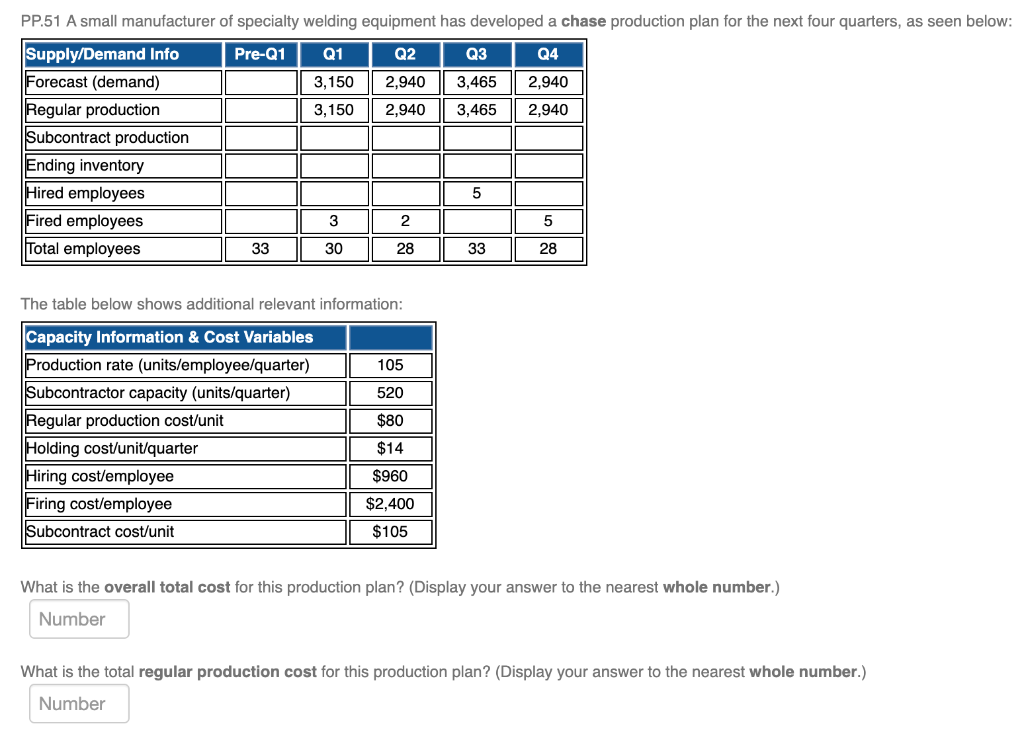

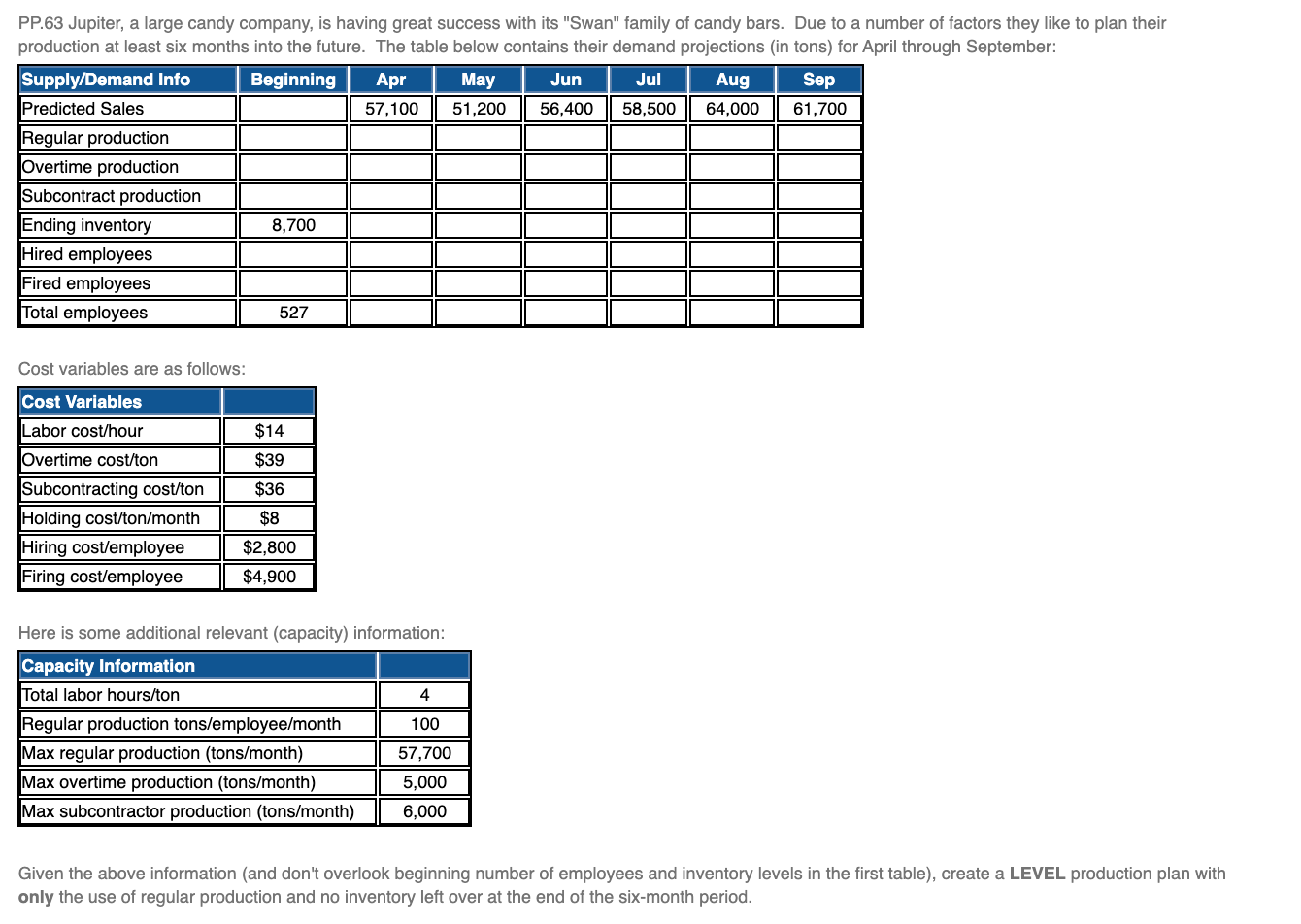

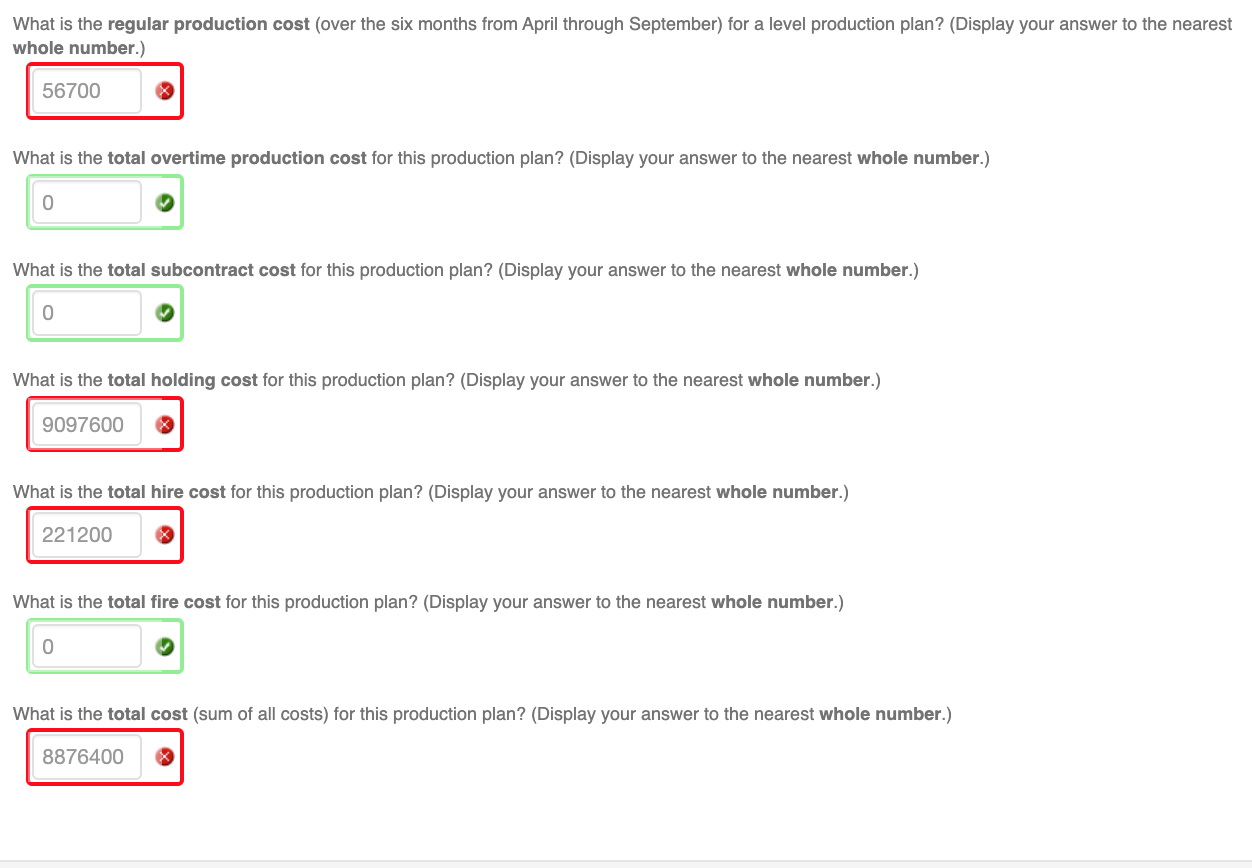

PP.51 A small manufacturer of specialty welding equipment has developed a chase production plan for the next four quarters, as seen below: Supply/Demand Info Pre-Q1 Q1 Q2 Q3 Q4 Forecast (demand) 3,150 2,940 || 3,465 | 2,940 Regular production | || 3,150 || 2,940 || 3,465 || 2,940 Subcontract production Ending inventory Hired employees Fired employees Total employees | 33 | 30 | 28 | 33 The table below shows additional relevant information: 105 520 $80 Capacity Information & Cost Variables Production rate (units/employee/quarter) Subcontractor capacity (units/quarter) Regular production cost/unit Holding cost/unit/quarter Hiring cost/employee Firing cost/employee Subcontract cost/unit $14 $960 $2,400 $105 What is the overall total cost for this production plan? (Display your answer to the nearest whole number.) Number What is the total regular production cost for this production plan? (Display your answer to the nearest whole number.) Number PP.63 Jupiter, a large candy company, is having great success with its "Swan" family of candy bars. Due to a number of factors they like to plan their production at least six months into the future. The table below contains their demand projections (in tons) for April through September: Supply/Demand Info Beginning | Apr May Jun Jul Aug Sep Predicted Sales 57,100 | 51,200 | 56,400 || 58,500 | 64,000 | 61,700 Regular production Overtime production Subcontract production Ending inventory 8,700 Hired employees Fired employees Total employees 527 Cost variables are as follows: $14 $39 Cost Variables Labor cost/hour Overtime cost/ton Subcontracting cost/ton Holding cost/ton/month Hiring cost/employee Firing cost/employee $36 $8 $2,800 $4,900 Here is some additional relevant (capacity) information: Capacity Information Total labor hours/ton Regular production tons/employee/month 100 Max regular production (tons/month) 57,700 Max overtime production (tons/month) 5,000 Max subcontractor production (tons/month) 6.000 Given the above information (and don't overlook beginning number of employees and inventory levels in the first table), create a LEVEL production plan with only the use of regular production and no inventory left over at the end of the six-month period. What is the regular production cost (over the six months from April through September) for a level production plan? (Display your answer to the nearest whole number.) 56700 What is the total overtime production cost for this production plan? (Display your answer to the nearest whole number.) What is the total subcontract cost for this production plan? (Display your answer to the nearest whole number.) What is the total holding cost for this production plan? (Display your answer to the nearest whole number.) 9097600 What is the total hire cost for this production plan? (Display your answer to the nearest whole number.) 221200 What is the total fire cost for this production plan? (Display your answer to the nearest whole number.) What is the total cost (sum of all costs) for this production plan? (Display your answer to the nearest whole number.) 8876400Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts