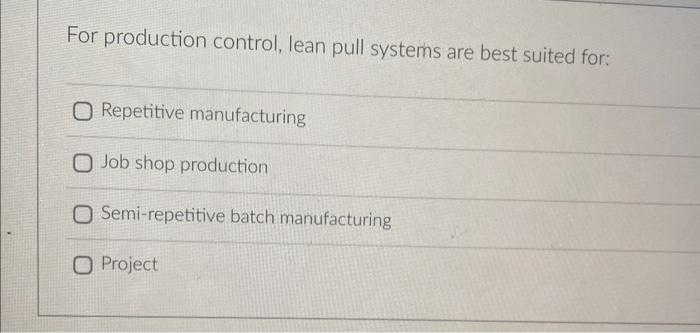

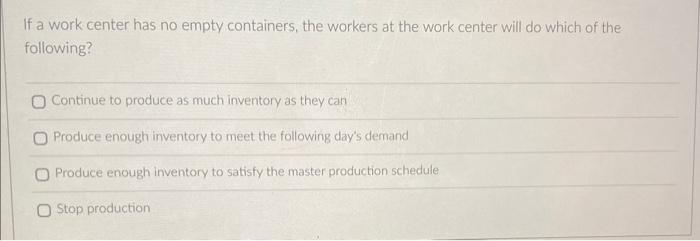

Question: For production control, lean pull systems are best suited for: Repetitive manufacturing Job shop production Semi-repetitive batch manufacturing Project If a work center has no

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock