Question: For the below problem if the true mean and standard deviation of the process are 6.05 and 0.04, a. Is the process capable of meeting

For the below problem if the true mean and standard deviation of the process are 6.05 and 0.04, a. Is the process capable of meeting its specification? Calculate its CP and CPk. b. What % of the cylinders if any are out of specs? ----

I'm seeking assistance on the above question. See below for the question it is referring to:

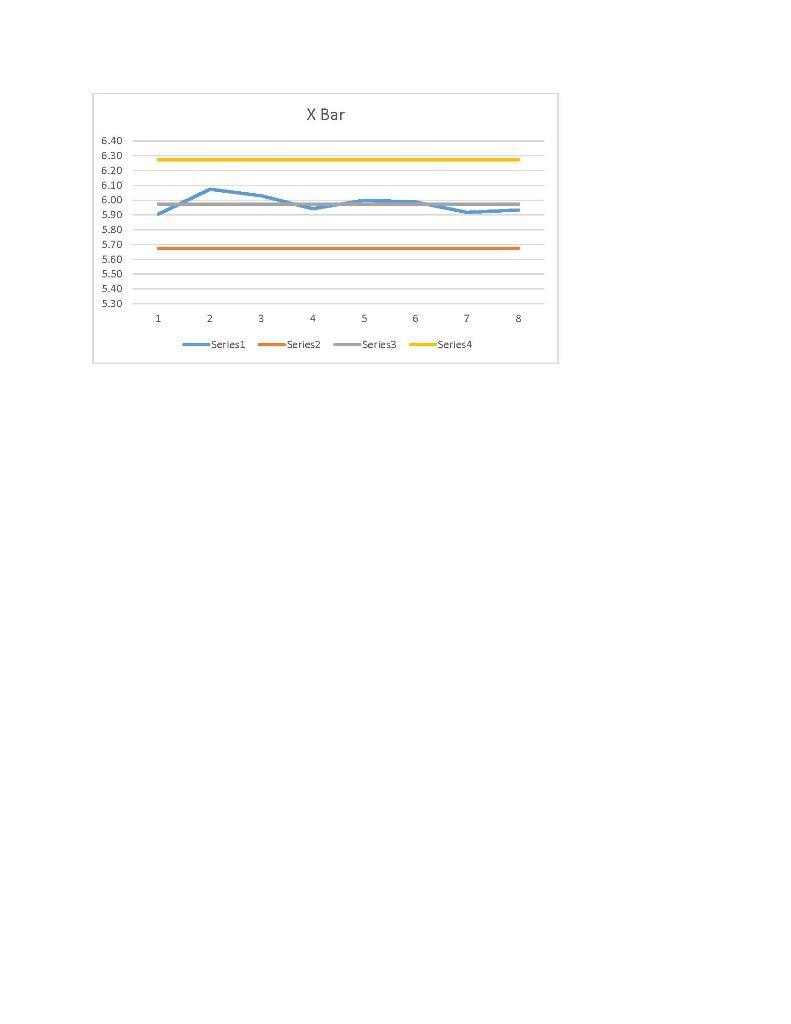

A quality control engineer monitors the quality of a cylinder production line. He regularly selects a sample of 5 units and measures the diameters. The specification requires the diameter to be 6 inches plus/minus 0.1 inch. The following is a record of the measurements. Is the production process in control? Yes

Please use X bar and R charts to make an assessment. Sample item 1 item 2 item 3 item 4 item 5 1 6.10 6.15 5.35 5.98 5.95 2 6.35 6.02 6.20 6.10 5.70 3 5.85 5.90 6.20 6.12 6.08 4 6.00 5.80 5.70 6.04 6.17 5 6.15 5.60 6.25 5.99 6.01 6 6.13 6.05 5.89 6.00 5.87 7 5.88 6.03 5.76 6.1 3 6.00 8 6.12 5.45 6.15 6.04 5.91

This is within the upper and lower control limits.

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts