Question: For the questions given below, check their answer and correct them if its wrong CASE: A company makes two models of lawnmowers, the standard Lawn

For the questions given below, check their answer and correct them if its wrong

CASE: A company makes two models of lawnmowers, the standard Lawn Mower 100 (part number 100) and the more powerful Lawn Mower 150 (part number 150). The following information is taken from the bill of material files for each of the lawn mowers.

Made from Part Part Number Quantity per LT Number 100 2 301 2 302 2 150 1 302 2 304 1 301 2 302 2 303 1 302 2 303 1 304 3

Description of the Case:

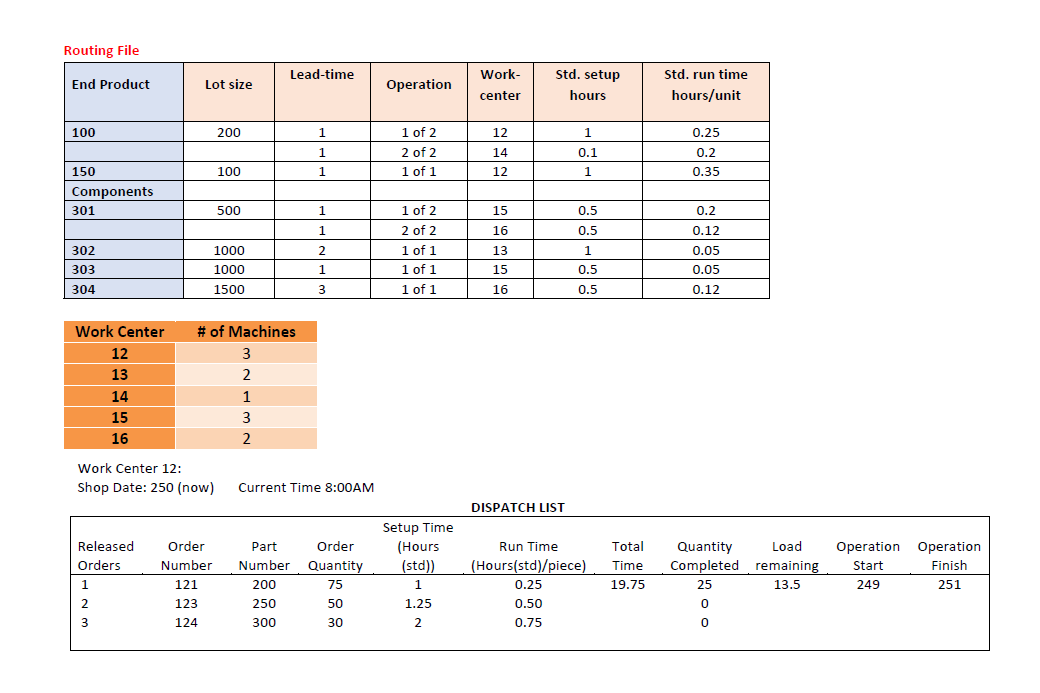

The company operates one 8-hour shift a day for five days a week. However the company loses on the average 5 hours a week to unscheduled maintenance for each machine (there are multiple machines in each work center, see below). On the other hand, the company has a well trained workforce and has recently demonstrated an efficiency level of 95%.

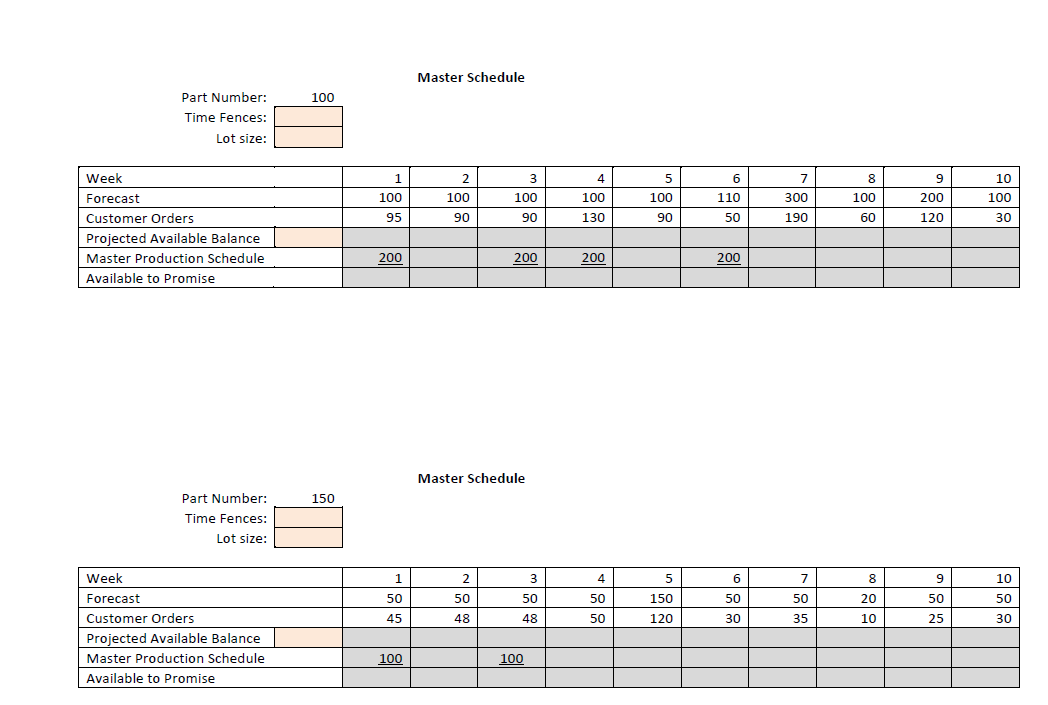

Partially completed Master Production Schedules for Lawn Mower 100 and 150 are given below. Lawn Mower 100 and 150 are built in lots of 200 and 100, respectively.

The MRP record for 100 shows that there are 200 units scheduled to be received in week 1. None is on hand. The lead time is two weeks and it is built in lots of 200.

The MRP record for 150 shows that there are 100 units scheduled to be received in week 1. None is on hand. The lead time is one week and it is built in lots of 100.

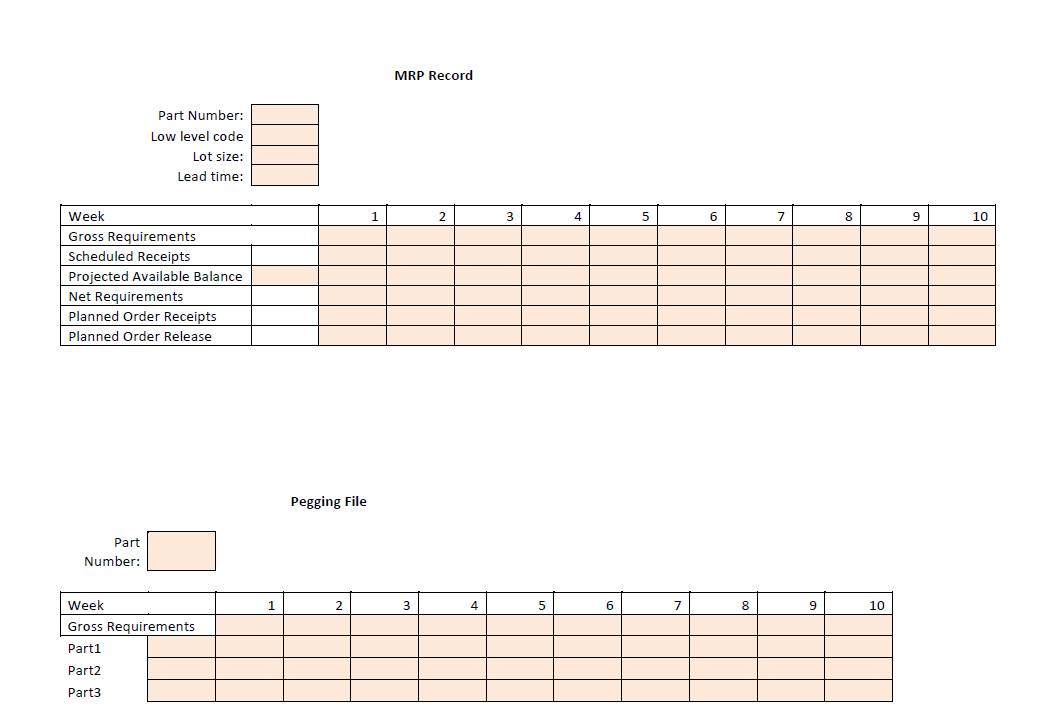

Part 301 is a component having a lead time of two weeks, and a lot size of 600. At present there is a lot scheduled to be received in week 1 and another in week 2.

Part 302 is a component with a lead time of two weeks, and a lot size of 1500. At present there are 500 on hand and a lot to be received in week 1.

Part 303 is a component having a lead time of one week, and a lot size of 1500. At present there is a lot scheduled to be received in week 1.

Part 304 is a component having a lead time of three weeks, and a lot size of 200. At present there are 220 on hand.

Question 1. From the information given, draw product trees for each of the finished goods. Answer 1 Finished Good #100: Level 0 100 LT=2 Level 1 301 (2) LT=2 302 (2) LT=2 Level 2 302 (2) LT=2 303 (1) LT = 1 Finished Good #150: Level 0 150 LT=1 Level 1 302 (2) LT=2 304 (1) LT =3 GIVEN DATA FILES

Master Schedule Part Number: Time Fences: Lot size: 100 Master Schedule Part Number: Time Fences: Lot size: MRP Record Pegging File Part Number: Routing File Work Center 12: Shop Date: 250 (now) Current Time 8:00AM Master Schedule Part Number: Time Fences: Lot size: 100 Master Schedule Part Number: Time Fences: Lot size: MRP Record Pegging File Part Number: Routing File Work Center 12: Shop Date: 250 (now) Current Time 8:00AM

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts