Question: For this project, students will design a two - stage reverted spur gear speed reducer to accommodate a reduction in speed from 1 8 0

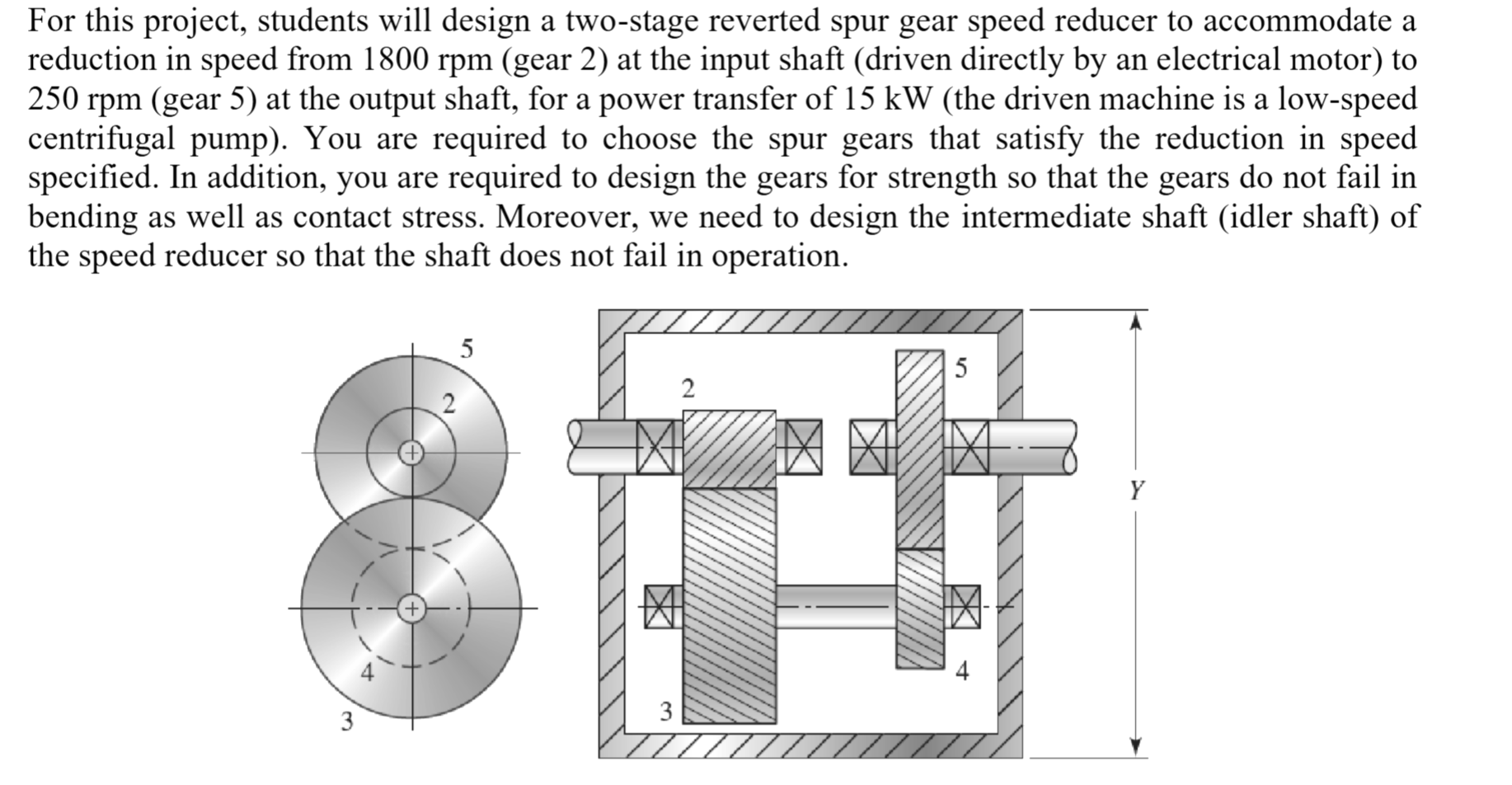

For this project, students will design a twostage reverted spur gear speed reducer to accommodate a reduction in speed from rpm gear at the input shaft driven directly by an electrical motor to rpm gear at the output shaft, for a power transfer of kW the driven machine is a lowspeed centrifugal pump You are required to choose the spur gears that satisfy the reduction in speed specified. In addition, you are required to design the gears for strength so that the gears do not fail in bending as well as contact stress. Moreover, we need to design the intermediate shaft idler shaft of the speed reducer so that the shaft does not fail in operation.

Find the force analysis transmitted load, radial load, and normal

load of all gears. But first, find the gear train value, speed ratios

for each stage, the minimum number of teeth for pinion and the maximum number of teeth in gear for each stage, the selected number of teeth for pinion and gear for each stage, the rotational speed of each shaft, the diametral pitch or module of each gear, the diameter of each gear, the torque acting on each shaft.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock