Question: Formulate as an LP model and solve using excel. Find the optimal production mix for the company. Perform a sensitivity analysis for this LP model.

Formulate as an LP model and solve using excel. Find the optimal production mix for the company. Perform a sensitivity analysis for this LP model.

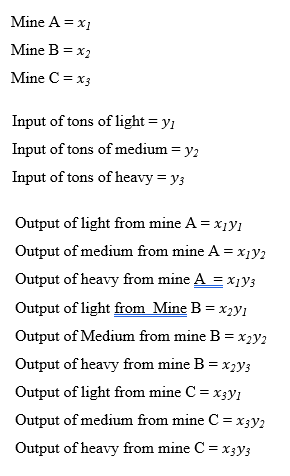

DECISION VARIABLES:

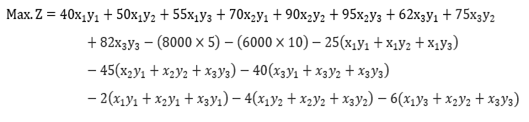

OBJECTIVE FUNCTION:

CONSTRAINTS:

Given problem:

Dragonball Z Mines Corporation (DZMC) operates strip coal-mining operation in southern Cebu province. Three mine sites (A, B, and C) currently are used, each producing coal of somewhat different sulfur and ash content. Coal from these sites is transported to a common crusher that grinds the coal into a finer mix. The coal is then washed to remove some of the sulfur and ash. In the washing process, the crushed coal is fed into a large tank containing a fluid. The cleaner coal floats and is removed for sale. Coal containing a heavier concentration of impurities sinks to the bottom and is discarded.

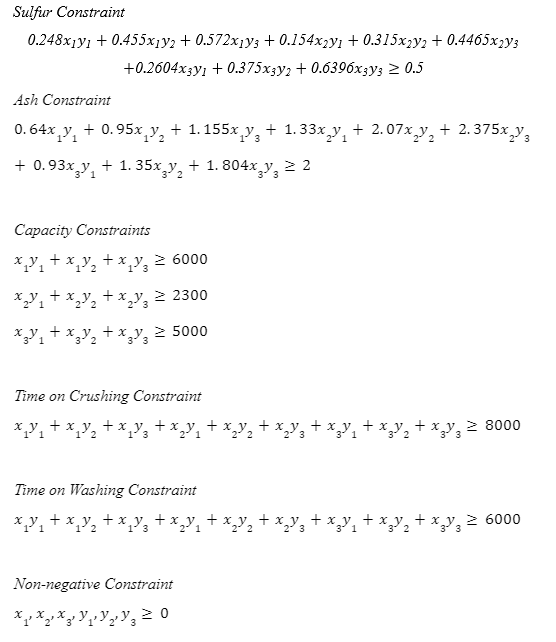

By using fluids of different densities (that is, having different specific gravities), the amount of impurities removed can be controlled. Referring to Table 1, three fluids are currently in use, called Light, Medium, and Heavy. With the Heavy fluid, a greater percentage of the coal is recovered (i.e., floats), but a smaller percentage of impurities is removed.

For example, if the coal from mine A is washed using Light fluid, only 40 percent of the coal is recovered for sale. This recovered coal contains 0.62 percent sulfur and 1.6 percent ash. On the other hand, the use of Heavy fluid increases the yield to 55 percent, but the recovered coal contains 1.04 percent sulfur and 2.1 percent ash.

The crushing and washing operation is set up so that any combination of coal from the mines can be used in conjunction with any of the fluids. After the washing operation, all the recovered coal is mixed to make one blend, sold by DZMC. Environmental requirements limit the blend to a maximum of 0.5 percent sulfur and 2.0 percent ash.

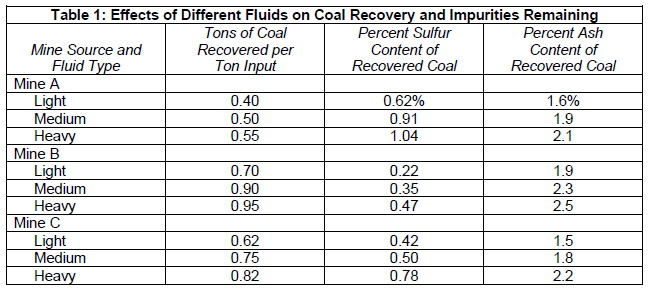

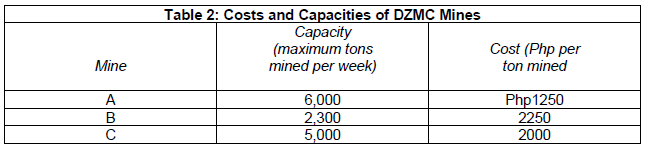

There are some other restrictions. The equipment available limits the amount that can be produced in each mine. See Table 2. The crusher can handle a maximum of 8,000 tons per week of unwashed coal on regular time, but can be worked overtime up to an additional 4,000 tons. The cost of the crushing operation is Php250 per ton of unwashed coal on regular time and Php375 per ton on overtime. The washing tank can handle up to 6,000 tons of recovered coal on regular time and an additional 3,000 tons on overtime. The cost of washing is Php500 per ton of recovered coal on regular time and Php750 on overtime.

The variable costs of operating each mine are also shown in Table 2. In addition, it costs Php100 per ton of unwashed coal for Light fluid, Php200 per ton of unwashed coal for Medium fluid, and Php300 per ton of unwashed coal for Heavy fluid. DZMC sells its coal blend for Php5,000 per ton.

Mine A=x1 Mine B=x2 Mine C=x3 Input of tons of light =y1 Input of tons of medium =y2 Input of tons of heavy =y3 Output of light from mine A=x1y1 Output of medium from mine A=x1y2 Output of heavy from mine A=x1y3 Output of light from Mine B=x2y1 Output of Medium from mine B=x2y2 Output of heavy from mine B=x2y3 Output of light from mine C=x3y1 Output of medium from mine C=x3y2 Output of heavy from mine C=x3y3 Max.Z=40x1y1+50x1y2+55x1y3+70x2y1+90x2y2+95x2y3+62x3y1+75x3y2+82x3y3(80005)(600010)25(x1y1+x1y2+x1y3)45(x2y1+x2y2+x3y3)40(x3y1+x3y2+x3y3)2(x1y1+x2y1+x3y1)4(x1y2+x2y2+x3y2)6(x1y3+x2y2+x3y3) Sulfur Constraint 0.248x1y1+0.455x1y2+0.572x1y3+0.154x2y1+0.315x2y2+0.4465x2y3+0.2604x3y1+0.375x3y2+0.6396x3y30.5 Ash Constraint 0.64x1y1+0.95x1y2+1.155x1y3+1.33x2y1+2.07x2y2+2.375x2y3+0.93x3y1+1.35x3y2+1.804x3y32 Capacity Constraints x1y1+x1y2+x1y36000x2y1+x2y2+x2y32300x3y1+x3y2+x3y35000 Time on Crushing Constraint x1y1+x1y2+x1y3+x2y1+x2y2+x2y3+x3y1+x3y2+x3y38000 Time on Washing Constraint x1y1+x1y2+x1y3+x2y1+x2y2+x2y3+x3y1+x3y2+x3y36000 Non-negative Constraint x1,x2,x3,y1,y2,y30 \begin{tabular}{|c|c|c|c|} \hline \multicolumn{3}{|c|}{ Table 1: Effects of Different Fluids on Coal Recovery and Impurities Remaining } \\ \hline Mine Source and Fluid Type & Tons of Coal Recovered per Ton Input & Percent Sulfur Content of Recovered Coal & Percent Ash Content of Recovered Coal \\ \hline Mine A & & & 1.6% \\ \hline Light & 0.40 & 0.62% & 1.9 \\ \hline Medium & 0.50 & 0.91 & 2.1 \\ \hline Heavy & 0.55 & 1.04 & 1.9 \\ \hline Mine B & & & 2.3 \\ \hline Light & 0.70 & 0.22 & 2.5 \\ \hline Medium & 0.90 & 0.35 & \\ \hline Heavy & 0.95 & 0.47 & 1.5 \\ \hline Mine C & & & 1.8 \\ \hline Light & 0.62 & 0.42 & 2.2 \\ \hline Medium & 0.75 & 0.50 & 0.78 \\ \hline Heavy & 0.82 & & \\ \hline \end{tabular} \begin{tabular}{|c|c|c|} \hline \multicolumn{3}{|c|}{ Table 2: Costs and Capacities of DZMC Mines } \\ \hline Mine & Capacity (maximum tons mined per week) & Cost (Php per ton mined \\ \hline A & 6,000 & Php1250 \\ \hline B & 2,300 & 2250 \\ \hline C & 5,000 & 2000 \\ \hline \end{tabular}Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts