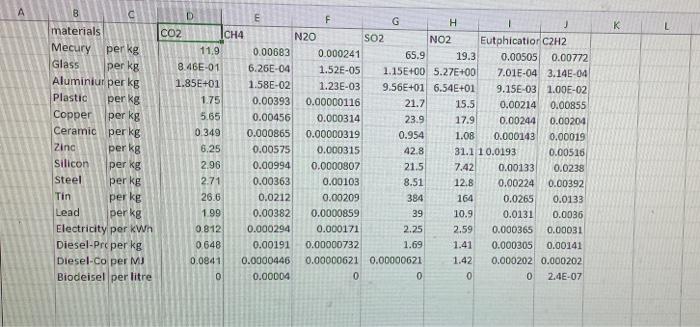

Question: G L 15.5 8 C D E F H materials CO2 CH4 N2O SOZ NO2 Eutphicatior C2H2 Mecury per kg 11,9 0.00683 0.000241 65.9 19.3

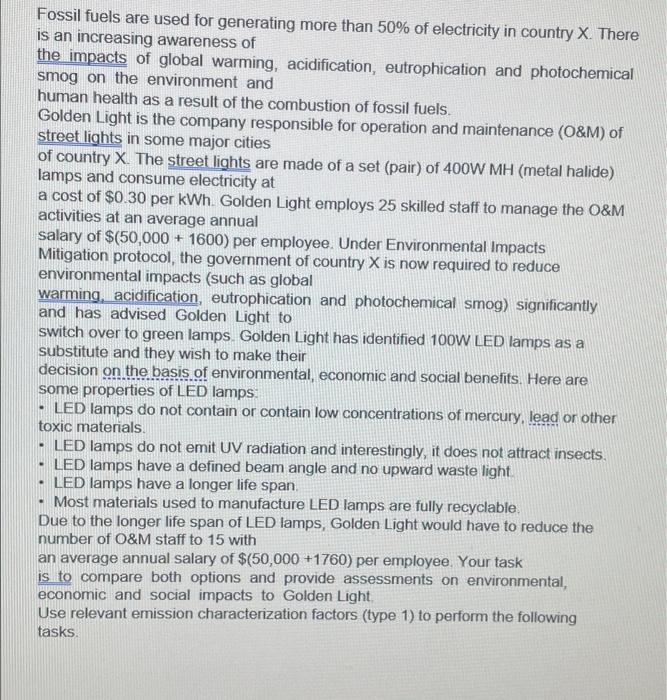

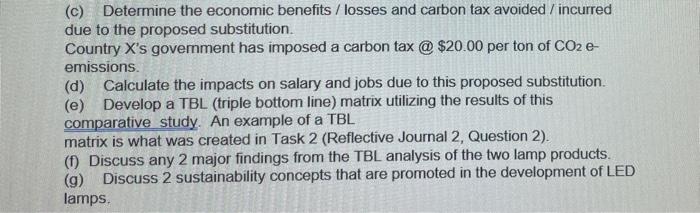

G L 15.5 8 C D E F H materials CO2 CH4 N2O SOZ NO2 Eutphicatior C2H2 Mecury per kg 11,9 0.00683 0.000241 65.9 19.3 0.00505 0.00772 Glass per kg 8.46E-01 6.26E-04 1.52E-05 1.15E+00 5.27E+00 7.01E-04 3.14 E-04 Aluminiur per kg 1.85E+01 1.58E-02 1.23E-03 9.56E+01 6.54E+01 9.15E-03 1.00E-02 Plastic per kg 1.75 0.00393 0.00000116 21.7 0.00214 0.00855 Copper per kg 5.65 0.00456 0.000314 23.9 17.9 0.00244 0.00204 Ceramic per kg 0.349 0.000865 0.00000319 0.954 1.08 0.000143 0.00019 Zinc per kg 6.25 0.00575 0.000315 42.8 31.1 10.0193 0.00516 Silicon per kg 2.96 0.00994 0.0000307 21.5 7.42 0.00133 0.0238 Steel per kg 2.71 0.00363 0.00103 8.51 12.8 0.00224 0.00392 Tin per ke 26.6 0.0212 0.00209 384 164 0.0265 0.0133 Lead per kg 199 0.00382 0.0000859 39 10.9 0.0131 0.0036 Electricity per kWh 0.812 0.000294 0.000171 2.25 2.59 0.000365 0.00031 Diesel-Preper kg 0.648 0.00191 0.00000732 1.69 1.41 0.000305 0.00141 Diesel-Co per M 0.0841 0.0000446 0.00000621 0.00000621 1.42 0.000202 0.000202 0 Biodeisel per litre 0.00004 0 0 0 2.4E-07 Fossil fuels are used for generating more than 50% of electricity in country X. There is an increasing awareness of the impacts of global warming, acidification, eutrophication and photochemical smog on the environment and human health as a result of the combustion of fossil fuels. Golden Light is the company responsible for operation and maintenance (O&M) of street lights in some major cities of country X. The street lights are made of a set (pair) of 400W MH (metal halide) lamps and consume electricity at a cost of $0.30 per kWh. Golden Light employs 25 skilled staff to manage the O&M activities at an average annual salary of $(50,000 + 1600) per employee. Under Environmental Impacts Mitigation protocol, the government of country X is now required to reduce environmental impacts (such as global warming, acidification, eutrophication and photochemical smog) significantly and has advised Golden Light to switch over to green lamps Golden Light has identified 100W LED lamps as a substitute and they wish to make their decision on the basis of environmental, economic and social benefits. Here are some properties of LED lamps. LED lamps do not contain or contain low concentrations of mercury, lead or other toxic materials LED lamps do not emit UV radiation and interestingly, it does not attract insects. LED lamps have a defined beam angle and no upward waste light LED lamps have a longer life span. Most materials used to manufacture LED lamps are fully recyclable Due to the longer life span of LED lamps, Golden Light would have to reduce the number of O&M staff to 15 with an average annual salary of $(50,000 +1760) per employee. Your task is to compare both options and provide assessments on environmental, economic and social impacts to Golden Light Use relevant emission characterization factors (type 1) to perform the following tasks . . (c) Determine the economic benefits / losses and carbon tax avoided / incurred due to the proposed substitution. Country X's government has imposed a carbon tax @ $20.00 per ton of CO2 e emissions (d) Calculate the impacts on salary and jobs due to this proposed substitution. (e) Develop a TBL (triple bottom line) matrix utilizing the results of this comparative study. An example of a TBL matrix is what was created in Task 2 (Reflective Journal 2, Question 2). (1) Discuss any 2 major findings from the TBL analysis of the two lamp products. (g) Discuss 2 sustainability concepts that are promoted in the development of LED lamps. Duration of operation of street lights per night - 10 hours . . 1 kWh = 3.6 M) Diesel cost - $ 1.57/liter Heating value of diesel - 38 MJ/liter Data for LED lamps Cost of each 100W LED lamp is $(200 + 2 x the sum of the last 2 digits of your UTC ID). Each has a life of 8 years The following materials/energy are required to manufacture each 100W LED lamp Aluminum - 150g Plastic -758 Glass - 50g Copper-358 Ceramic - 288 Silicon Sealant-668 Zinc - 108 Tin - 40g Lead-28 Steel - 100g Electricity - 75 M) Data for MH lamps . . . . The life of each MH lamp is 2 years Cost of each 400W MH lamp is $135.00+ the sum of the last 2 digits of your UTCID) cost of safe disposal of metal halide lamp is $15.00 per lamp Diesel operated lift truck, which is used for replacement of lamps consumes an average 4 liter diesel per MH lamp Following materials/energy are required to manufacture each 400w MH lamp Glass - 1958 Steel - 428 Mercury - 50mg Copper - 108 Electricity -40MU Notes: . . Use relevant emission characterization factors (type 1) uploaded on canvas. Please pay attention to units and carryout necessary conversions to maintain the same units for the calculations, Global warming Impact (KeCo. e) = 1 x K&CO. + 28 x Kg CH +265 KR NO Acidification Impact (kg so, e-) = 1 Kg 50; +1.4 XNO. Photochemical smog impact (& CHa e-) - 1 Kg CH +0.006 Ke CHE

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts