Question: Given the following production plan, use a level production strategy to compute the monthly production, ending inventory/(backlog), net requirements and required workforce levels. A worker

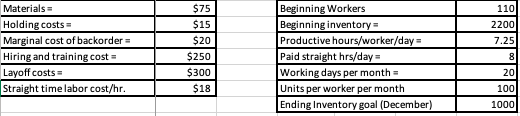

Given the following production plan, use a level production strategy to compute the monthly production, ending inventory/(backlog), net requirements and required workforce levels. A worker can produce 100 units per month. Assume that the beginning inventory in January is 2200 units, and the firm desires to have 1000 units of inventory at the end of December.

| Month | Jan | Feb | Mar | Apr | May | Jun | Jul | Aug | Sept | Oct | Nov | Dec |

| Demand | 15,400 | 13,250 | 9,000 | 9,700 | 14,650 | 16,000 | 22,400 | 23,100 | 19,050 | 17,400 | 14,000 | 12,300 |

What is the total cost?

What month has the highest ending inventory level?

What month has the highest backorder cost?

What is the difference of total cost comparing the level strategy to the chase strategy?

Materials Holding costs = Marginal cost of backorder Hiring and training cost = Layoff costs Straight time labor cost/hr. $75 $15 $20 $250 $300 $18 Beginning Workers Beginning inventory = Productive hours/worker/day Paid straight hrs/day- Working days per month Units per worker per month Ending Inventory goal (December) 110 2200 7.25 8 20 100 1000 Materials Holding costs = Marginal cost of backorder Hiring and training cost = Layoff costs Straight time labor cost/hr. $75 $15 $20 $250 $300 $18 Beginning Workers Beginning inventory = Productive hours/worker/day Paid straight hrs/day- Working days per month Units per worker per month Ending Inventory goal (December) 110 2200 7.25 8 20 100 1000

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock