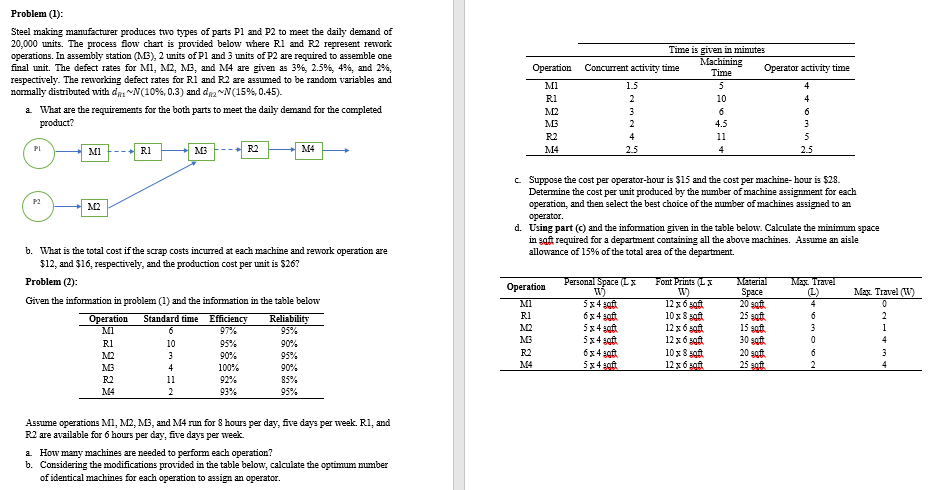

Question: Given the information in problem (1) and the information in the table below Operation Standard time Efficiency Reliability M1 6 97% 95% R1 10 95%

Given the information in problem (1) and the information in the table below

| Operation | Standard time | Efficiency | Reliability |

| M1 | 6 | 97% | 95% |

| R1 | 10 | 95% | 90% |

| M2 | 3 | 90% | 95% |

| M3 | 4 | 100% | 90% |

| R2 | 11 | 92% | 85% |

| M4 | 2 | 93% | 95% |

Assume operations M1, M2, M3, and M4 run for 8 hours per day, five days per week. R1, and R2 are available for 6 hours per day, five days per week.

- How many machines are needed to perform each operation?

- Considering the modifications provided in the table below, calculate the optimum number of identical machines for each operation to assign an operator.

| Time is given in minutes | |||

| Operation | Concurrent activity time | Machining Time | Operator activity time |

| M1 | 1.5 | 5 | 4 |

| R1 | 2 | 10 | 4 |

| M2 | 3 | 6 | 6 |

| M3 | 2 | 4.5 | 3 |

| R2 | 4 | 11 | 5 |

| M4 | 2.5 | 4 | 2.5 |

- Suppose the cost per operator-hour is $15 and the cost per machine- hour is $28. Determine the cost per unit produced by the number of machine assignment for each operation, and then select the best choice of the number of machines assigned to an operator.

- Using part (c) and the information given in the table below. Calculate the minimum space in sqft required for a department containing all the above machines. Assume an aisle allowance of 15% of the total area of the department.

| Operation | Personal Space (L x W) | Font Prints (L x W) | Material Space | Max. Travel (L) | Max. Travel (W) |

| M1 | 5 x 4 sqft | 12 x 6 sqft | 20 sqft | 4 | 0 |

| R1 | 6 x 4 sqft | 10 x 8 sqft | 25 sqft | 6 | 2 |

| M2 | 5 x 4 sqft | 12 x 6 sqft | 15 sqft | 3 | 1 |

| M3 | 5 x 4 sqft | 12 x 6 sqft | 30 sqft | 0 | 4 |

| R2 | 6 x 4 sqft | 10 x 8 sqft | 20 sqft | 6 | 3 |

| M4 | 5 x 4 sqft | 12 x 6 sqft | 25 sqft | 2 | 4 |

Problem (1): Steel making manufacturer produces two types of parts P1 and P2 to meet the daily demand of 20,000 units. The process flow chart is provided below where Rl and R2 represent rework operations. In assembly station (MG), 2 units of P1 and 3 units of P2 are required to assemble one final unit. The defect rates for MI, M2, M3, and M4 are given as 3%, 2.5%, 4%, and 2%, respectively. The reworking defect rates for Ri and R2 are assumed to be random variables and normally distributed with d (10%, 0.3) and d 2 (15%, 0.45). a What are the requirements for the both parts to meet the daily demand for the completed product? Operation MI Ri M2 MB R2 M4 Time is given in minutes Machining Concurrent activity time Time Operator activity time 1.5 5 4 10 4 3 6 6 2 4.5 3 4 11 5 25 4 2.5 PL MI RI M3 R2 M4 P2 M2 c Suppose the cost per operator-hour is $15 and the cost per machine-hour is $28. Determine the cost per unit produced by the number of machine assignment for each operation, and then select the best choice of the number of machines assigned to an operator. d. Using part (C) and the information given in the table below. Calculate the minimum space in soft required for a department containing all the above machines. Assume an aisle allowance of 15% of the total area of the department. Font Prints (LX Material Space 20 sqf b. What is the total cost if the scrap costs incurred at each machine and rework operation are $12, and $16, respectively, and the production cost per unit is $26? Problem (2): Given the information in problem (1) and the information in the table below Operation Standard time Efficiency Reliability MI 6 RI 10 90% NO2 3 90% 95% M3 4 100% 90% R2 11 92% 85% N4 2 93% 95% 25908 Operation MI RI M2 N3 R2 M4 Personal Space (Lx W) 5x 450 6x40ft 5x4 30ft 5x4 30ft 63 49067 53 430 12 6 Soft 10 x 80 12 x 6 308 12 x 60 10 x 80 12 x 6 ft Nax. Irave. (L) 4 6 3 0 6 2 15 sqft 30 904 20 sqft 25 soft Max. Travel (W) 0 2 1 4 3 4 Assume operations MI, M2, M3, and M4 run for 8 hours per day, five days per week. Rl, and R2 are available for 6 hours per day, five days per week. 2. How many machines are needed to perform each operation? b. Considering the modifications provided in the table below, calculate the optimum number of identical machines for each operation to assign an operator

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts