Question: Group-4 Part-1 (A) A manual assembly line operates with a mechanized conveyor. The conveyor moves at a speed of 5 ft/min, and the spacing between

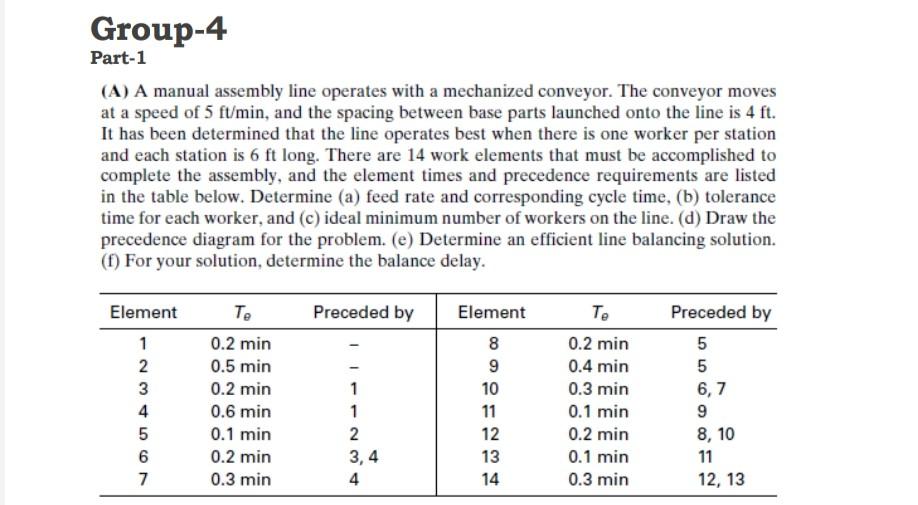

Group-4 Part-1 (A) A manual assembly line operates with a mechanized conveyor. The conveyor moves at a speed of 5 ft/min, and the spacing between base parts launched onto the line is 4 ft. It has been determined that the line operates best when there is one worker per station and each station is 6 ft long. There are 14 work elements that must be accomplished to complete the assembly, and the element times and precedence requirements are listed in the table below. Determine (a) feed rate and corresponding cycle time, (b) tolerance time for each worker, and (c) ideal minimum number of workers on the line. (d) Draw the precedence diagram for the problem. (e) Determine an efficient line balancing solution. (1) For your solution, determine the balance delay. Preceded by Element 1 2 3 4 5 6 7 TE 0.2 min 0.5 min 0.2 min 0.6 min 0.1 min 0.2 min 0.3 min 1 1 2 3,4 4 Element 8 9 10 11 12 13 14 Te 0.2 min 0.4 min 0.3 min 0.1 min 0.2 min 0.1 min 0.3 min Preceded by 5 5 6,7 9 8, 10 11 12, 13

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock