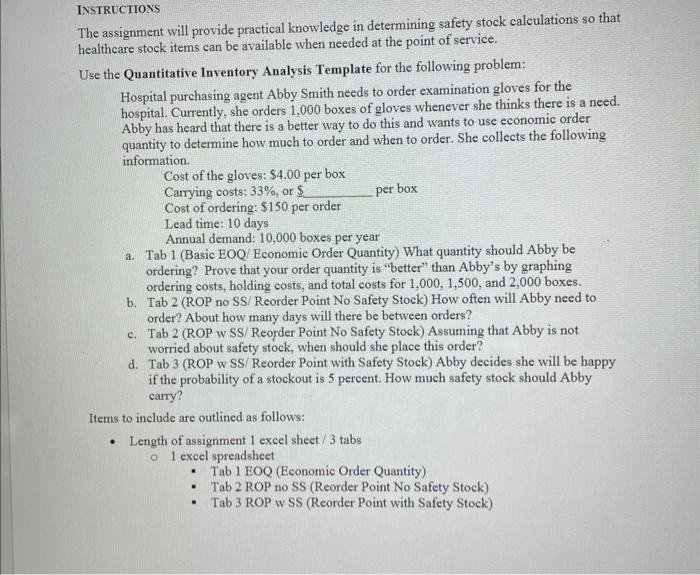

Question: he assignment will provide practical knowledge in determining safety stock calculations so that ealthcare stock items can be available when needed at the point of

he assignment will provide practical knowledge in determining safety stock calculations so that ealthcare stock items can be available when needed at the point of service. the Quantitative Inventory Analysis Template for the following problem: Hospital purchasing agent Abby Smith needs to order examination gloves for the hospital. Currently, she orders 1,000 boxes of gloves whenever she thinks there is a need. Abby has heard that there is a better way to do this and wants to use economic order quantity to determine how much to order and when to order. She collects the following information. Cost of the gloves: $4.00 per box Carrying costs: 33%, or $ per box Cost of ordering: $150 per order Lead time: 10 days Annual demand: 10,000 boxes per year a. Tab 1 (Basic EOQ/ Economic Order Quantity) What quantity should Abby be ordering? Prove that your order quantity is "better" than Abby's by graphing ordering costs, holding costs, and total costs for 1,000,1,500, and 2,000 boxes. b. Tab 2 (ROP no SS/ Reorder Point No Safety Stock) How often will Abby need to order? About how many days will there be between orders? c. Tab 2 (ROP w SS/ Reorder Point No Safety Stock) Assuming that Abby is not worried about safety stock, when should she place this order? d. Tab 3 (ROP w SS/ Reorder Point with Safety Stock) Abby decides she will be happy if the probability of a stockout is 5 percent. How much safety stock should Abby carry? Items to include are outlined as follows: - Length of assignment 1 excel sheet /3 tabs 1 excel spreadsheet - Tab 1 EOQ (Economic Order Quantity) - Tab 2 ROP no SS (Reorder Point No Safety Stock) - Tab 3 ROP w SS (Reorder Point with Safety Stock) he assignment will provide practical knowledge in determining safety stock calculations so that ealthcare stock items can be available when needed at the point of service. the Quantitative Inventory Analysis Template for the following problem: Hospital purchasing agent Abby Smith needs to order examination gloves for the hospital. Currently, she orders 1,000 boxes of gloves whenever she thinks there is a need. Abby has heard that there is a better way to do this and wants to use economic order quantity to determine how much to order and when to order. She collects the following information. Cost of the gloves: $4.00 per box Carrying costs: 33%, or $ per box Cost of ordering: $150 per order Lead time: 10 days Annual demand: 10,000 boxes per year a. Tab 1 (Basic EOQ/ Economic Order Quantity) What quantity should Abby be ordering? Prove that your order quantity is "better" than Abby's by graphing ordering costs, holding costs, and total costs for 1,000,1,500, and 2,000 boxes. b. Tab 2 (ROP no SS/ Reorder Point No Safety Stock) How often will Abby need to order? About how many days will there be between orders? c. Tab 2 (ROP w SS/ Reorder Point No Safety Stock) Assuming that Abby is not worried about safety stock, when should she place this order? d. Tab 3 (ROP w SS/ Reorder Point with Safety Stock) Abby decides she will be happy if the probability of a stockout is 5 percent. How much safety stock should Abby carry? Items to include are outlined as follows: - Length of assignment 1 excel sheet /3 tabs 1 excel spreadsheet - Tab 1 EOQ (Economic Order Quantity) - Tab 2 ROP no SS (Reorder Point No Safety Stock) - Tab 3 ROP w SS (Reorder Point with Safety Stock)