Question: Hello. I just need help with the last question #6 At JimCo. Vise Company, two types of Vises are fabricated for profit, Type 1 and

Hello. I just need help with the last question #6

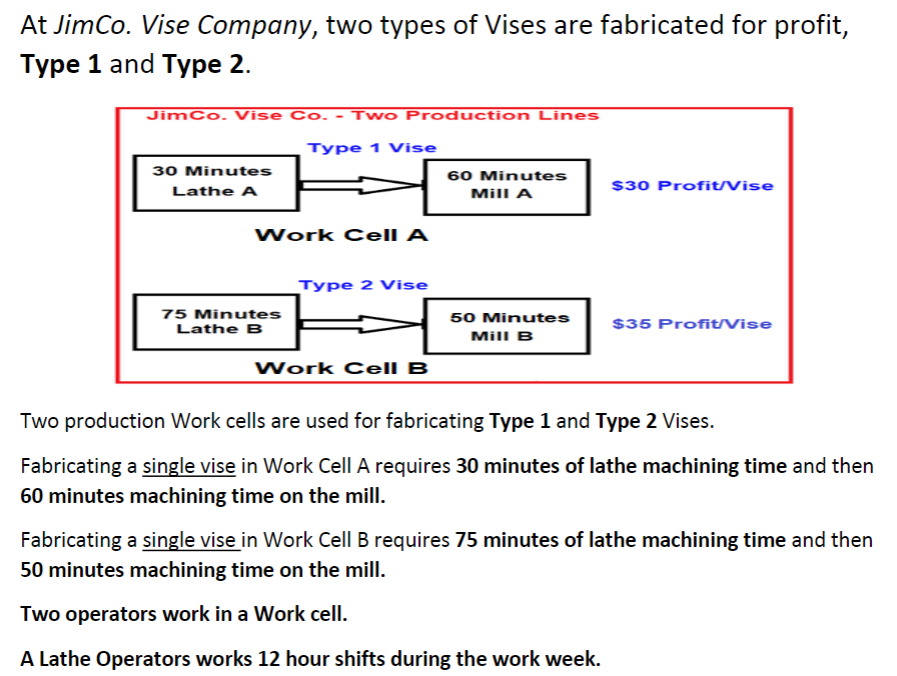

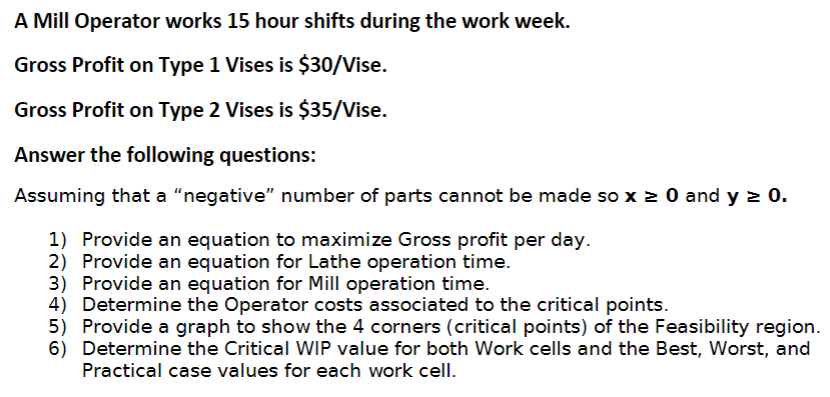

At JimCo. Vise Company, two types of Vises are fabricated for profit, Type 1 and Type 2. Two production Work cells are used for fabricating Type 1 and Type 2 Vises. Fabricating a single vise in Work Cell A requires 30 minutes of lathe machining time and then 60 minutes machining time on the mill. Fabricating a single vise in Work Cell B requires 75 minutes of lathe machining time and then 50 minutes machining time on the mill. Two operators work in a Work cell. A Lathe Operators works 12 hour shifts during the work week. A Mill Operator works 15 hour shifts during the work week. Gross Profit on Type 1 Vises is $30/ Vise. Gross Profit on Type 2 Vises is $35/ Vise. Answer the following questions: Assuming that a "negative" number of parts cannot be made so x0 and y0. 1) Provide an equation to maximize Gross profit per day. 2) Provide an equation for Lathe operation time. 3) Provide an equation for Mill operation time. 4) Determine the Operator costs associated to the critical points. 5) Provide a graph to show the 4 corners (critical points) of the Feasibility region. 6) Determine the Critical WIP value for both Work cells and the Best, Worst, and Practical case values for each work cell

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts