Question: Hello, I need help finding a DC motor and gearbox to pair and complete the following rubric below. Please, if possible, include the name of

Hello, I need help finding a DC motor and gearbox to pair and complete the following rubric below. Please, if possible, include the name of the gearbox and motor that's being used as well. Thanks

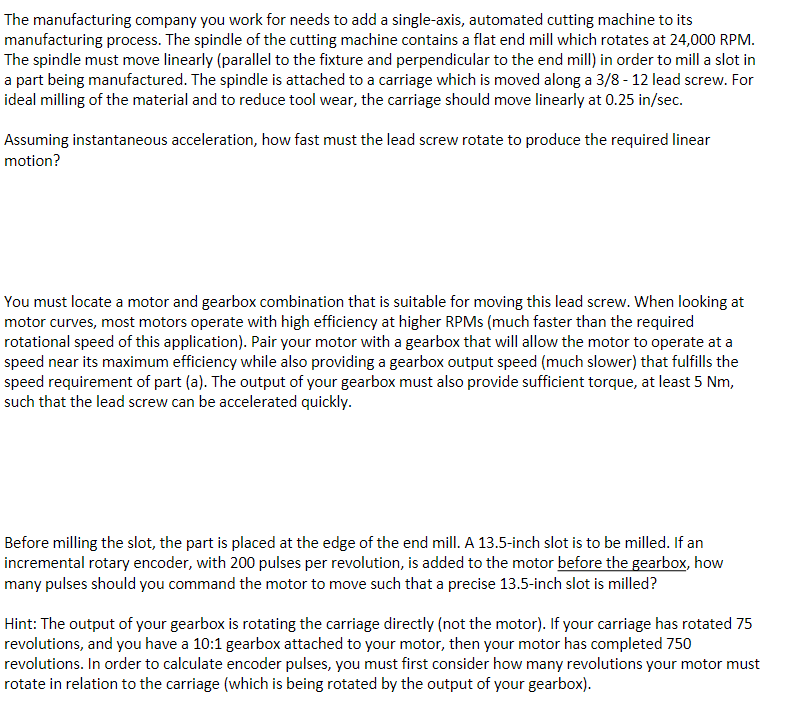

The manufacturing company you work for needs to add a singleaxis, automated cutting machine to its

manufacturing process.

The spindle of the cutting machine contains a flat end mill which rotates at RPM

The spindle must move linearly parallel to the fixture and perpendicular to the end mill in order to mill a slot in

a part being manufactured. The spindle is attached to a carriage which is moved along a lead screw. For

ideal milling of the material and to reduce tool wear, the carriage should move linearly at insec

Assuming instantaneous acceleration, how fast must the lead screw rotate to produce the required linear

motion?

You must locate a motor and gearbox combination that is suitable for moving this lead screw. When looking at

motor curves, most motors operate with high efficiency at higher RPMs much faster than the required

rotational speed of this application Pair your motor with a gearbox that will allow the motor to operate at a

speed near its maximum efficiency while also providing a gearbox output speed much slower that fulfills the

speed requirement of part a The output of your gearbox must also provide sufficient torque, at least Nm

such that the lead screw can be accelerated quickly.

Before milling the slot, the part is placed at the edge of the end mill. A inch slot is to be milled. If an

incremental rotary encoder, with pulses per revolution, is added to the motor before the gearbox, how

many pulses should you command the motor to move such that a precise inch slot is milled?

Hint: The output of your gearbox is rotating the carriage directly not the motor If your carriage has rotated

revolutions, and you have a : gearbox attached to your motor, then your motor has completed

revolutions. In order to calculate encoder pulses, you must first consider how many revolutions your motor must

rotate in relation to the carriage which is being rotated by the output of your gearbox

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock