Question: Help on C & E only please. Use Aspen plus. Show data and work please for everything. For part C also answer: What was found

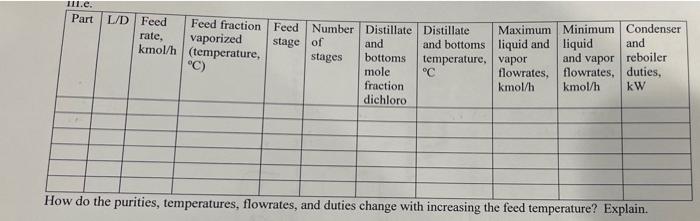

a. We want a distillate product that is 92.0 mol\% 1,2-dichloroethane and a bottoms that is 8.0 mol\% 1.2-dichlorocthane. Since Aspen Plus is a simulator program, it dees not allow you to specify these concentrations directly. Look at the report from the previous run. If you scroll down to Mole-x-profile, the values for stage I (liquid leaving the condenser) are the distillate mole fractions and the values for stage 23 (liquid leaving the reboiler) are the bottoens mole fractions. Both of the purities are. b. First, wet a dittillate flow rate that will satisfy the mass balance. Find D and B from mass balances. Do this calculation accurately or you may never get the solotion you want. (Hint: D 60 is not the correct value.) Then try different columns (change number of stages and feed location) to find some that work. Use LD - 2.0 Pick a reasonable number of stages and a reasonable feod stage (Try N=21 and fecd at 9 [vapor] to start). Simulate the column, and check the distillste and botioms neole fractions. They should be purer than yoa want. Also, check the K values, and calculate the relative volatility at the top, feed stage, and botiom of the colunin to see how c. Find the optimuns feed stage by irying different feed stages to see which one gives the greatest separation (highert dichlorocthane mole fraction ia distillale and Jowest in botioms). (Hins: Try increasing N /eod inutaally.) Then decrease N (try 19, then 17) until the coluein no longer moets the specifications for distillate and bottons, Nons find the optinsum feed stage oven though you are not satisfying the specs (the optimam feed stage mught saticfy the specs). Note that since the natio of optinum foud of sages by one stage. If the optimum agais. If this works, you are done with this step. If the separation is better than the spocs, wes if you can reduce the total number e. Retam to p1atm and yesir answer for pare III.e. \begin{tabular}{|l|l|l|l|l|l|l|l|l|l|l|} \hline Part & L/D & Feed rate, kmol/h & Feed fraction vaporized (temperature, C) & Feed stage & Number of stages & Distillate and bottoms mole fraction dichloro & Distillate and bottoms temperature, C & Maximum liquid and vapor flowrates, kmol/h & Minimum liquid and vapor flowrates, kmol/h & Condenser and reboiler duties, kW \\ \hline & & & & & & & \\ \hline & & & & & & & \\ \hline \end{tabular} How do the purities, temperatures, flowrates, and duties change with increasing the feed temperature? Explain

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts