Question: Help Please!!! Homework: Chapter 5 Homework Question 5, E5-36A (simi... Part 2 of 4 HW Score: 80.76%, 4.04 of 5 points Points: 0.16 of 1

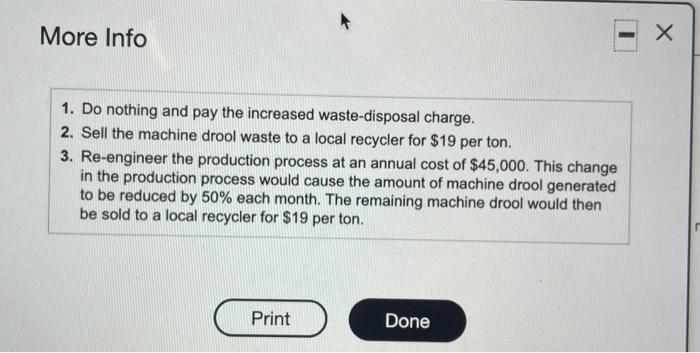

Homework: Chapter 5 Homework Question 5, E5-36A (simi... Part 2 of 4 HW Score: 80.76%, 4.04 of 5 points Points: 0.16 of 1 Save Sampson Industries manufactures plastic bottles for the food industry On average, Sampson pays $76 per ton for its plastics. Sampson's waste disposal company has increased its waste disposal charge to $54 per ton for cold and inert waste Sampson generates a total of 500 tons of wasto per month Sampson's managers have been evaluating the production processes for areas to cut waste. In the process of making plastic bottes, a certain amount of machine "droorocour Machine drool is the excess plastic that drips of the machine between molds. In the past. Sampson has discarded the machine drool. in an average month, 170 tons of machine drool is generated Management has arrived at three possible courses of action for the machine drool issue (Click the icon to view the courses of action) Read the requirements Annual cost Material cost of machine drool (plastic) 155,040 Disposal cost 110,180 265.200 Total annual cost Requirement 2. How much would the company save per year (net) if the machine drool were to be sold to the local recycler? (Udo parentheses or a minun sign to show amounts that will reduce the annual savings. If an input field is not used in the table, leave the pot field empty, do not select a fobol or entera 200) Annual savings (net) Roduction in direct material coats (c) Reduction in waste disposa COS Amount received from local recycler Annual cost to re-engineer Total annual savings (net Help Me Solve This Video Get More Help Clear All Check Answer More Info 1. Do nothing and pay the increased waste-disposal charge. 2. Sell the machine drool waste to a local recycler for $19 per ton. 3. Re-engineer the production process at an annual cost of $45,000. This change in the production process would cause the amount of machine drool generated to be reduced by 50% each month. The remaining machine drool would then be sold to a local recycler for $19 per ton. Print Done

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts