Question: help please! need the second half zoom in to view QUESTION 2 A company is about to begin production of a new product. The manager

help please! need the second half

zoom in to view

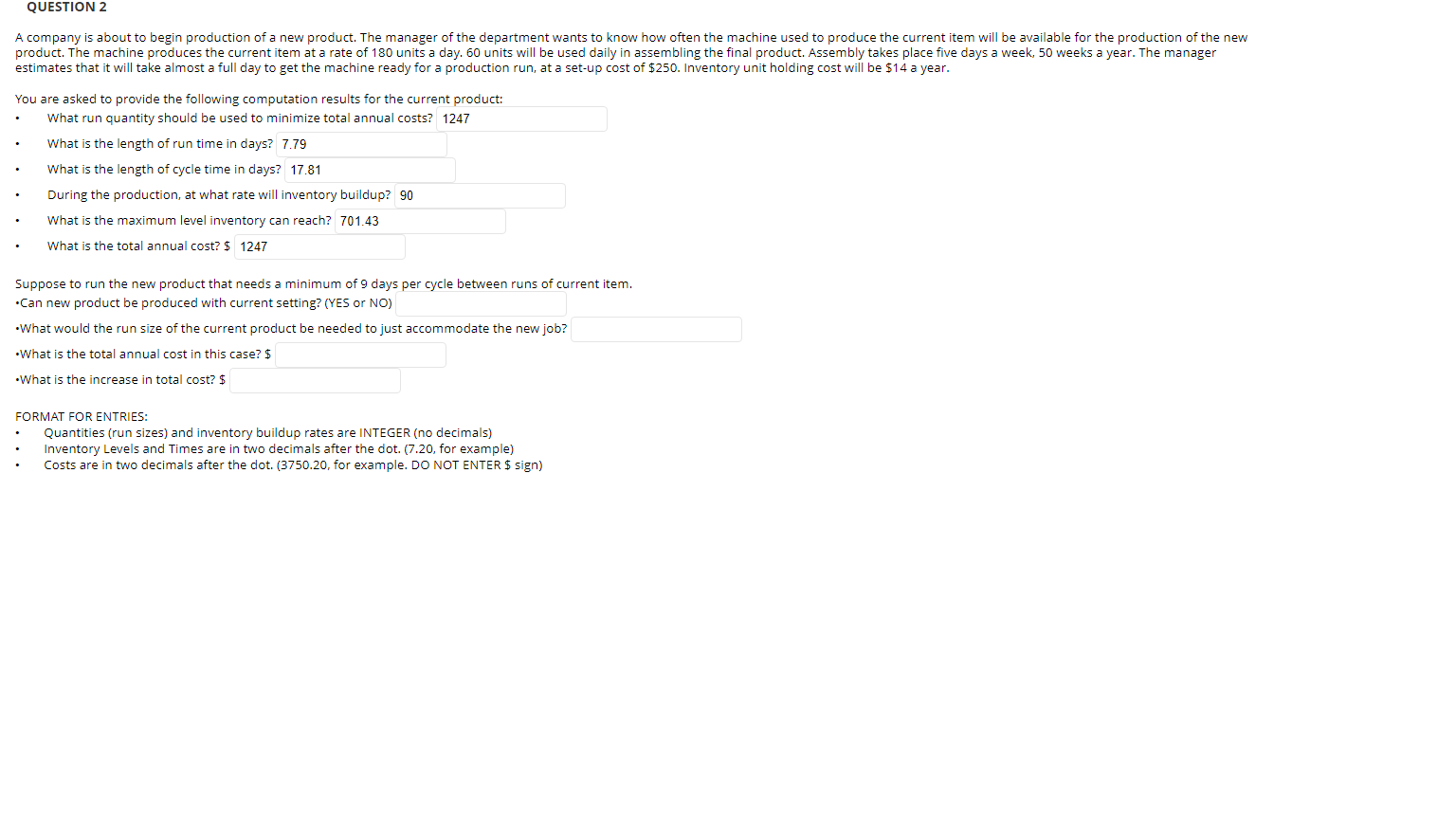

QUESTION 2 A company is about to begin production of a new product. The manager of the department wants to know how often the machine used to produce the current item will be available for the production of the new product. The machine produces the current item at a rate of 180 units a day. 60 units will be used daily in assembling the final product. Assembly takes place five days a week, 50 weeks a year. The manager estimates that it will take almost a full day to get the machine ready for a production run, at a set-up cost of $250. Inventory unit holding cost will be $14 a year. You are asked to provide the following computation results for the current product: What run quantity should be used to minimize total annual costs? 1247 What is the length of run time in days? 7.79 What is the length of cycle time in days? 17.81 During the production, at what rate will inventory buildup? 90 What is the maximum level inventory can reach? 701.43 What is the total annual cost? $ 1247 Suppose to run the new product that needs a minimum of 9 days per cycle between runs of current item. Can new product be produced with current setting? (YES or NO) What would the run size of the current product be needed to just accommodate the new job? What is the total annual cost in this case? $ What is the increase in total cost? $ FORMAT FOR ENTRIES: Quantities (run sizes) and inventory buildup rates are INTEGER (no decimals) Inventory Levels and Times are in two decimals after the dot. (7.20, for example) Costs are in two decimals after the dot. (3750.20, for example. DO NOT ENTER $ sign) Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock