Question: help. please show all calculations via cell referencing in excel or by hand Chapter 3, Problems, 131 - work only parts b) through d); the

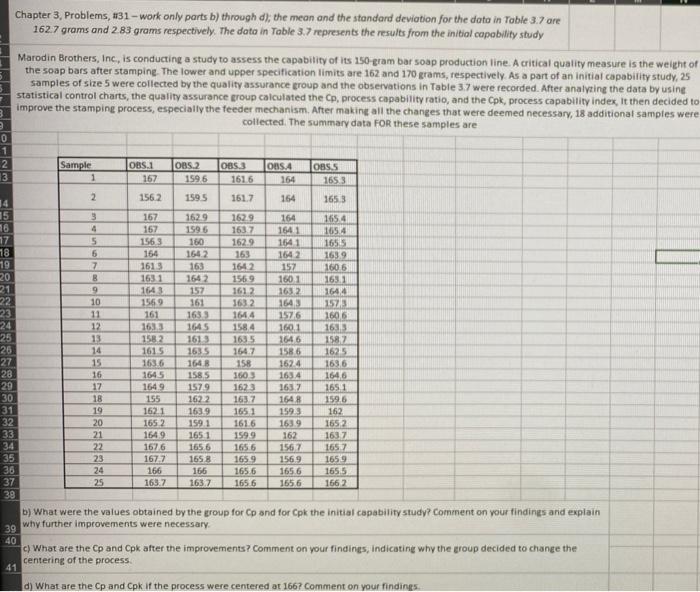

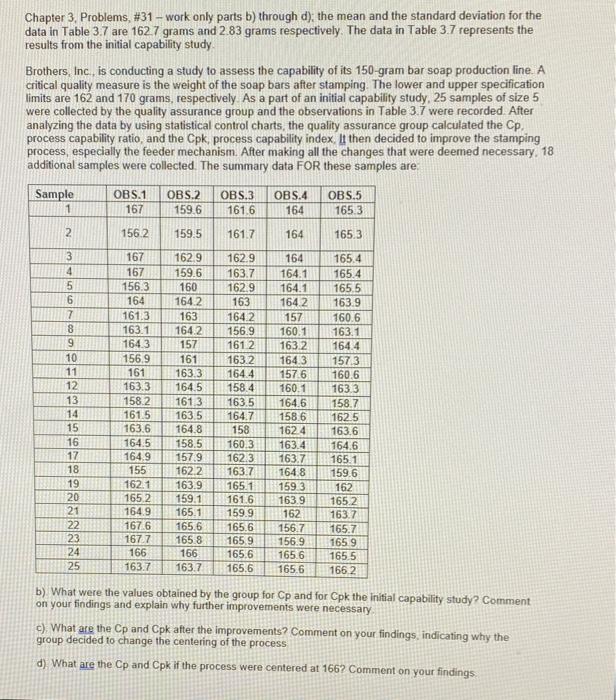

Chapter 3, Problems, 131 - work only parts b) through d); the mean and the standard deviotion for the data in Toble 3.7 are 162.7 grams and 2.83 grams respectively. The dato in Table 3.7 represents the results from the initiol copobility study Marodin Brothers, Inc, is conducting a study to assess the capability of its 150 -gram bar soap production line. A critical quality measure is the weight of the soap bars after stampine. The lower and upper specification limits are 162 and 170 grams, respectively. As a part of an initial capability study, 25 samples of size 5 were collected by the quality assurance group and the observations in Table 3.7 were recorded. After analyting the data by using statistical control charts, the quality assurance aroup calculated the Cp, process capability ratio, and the Cpk, process capability index, it then decided to improve the stamping process, especialfy the feeder mechanism. After makint all the changes that were deemed necessary, 18 additional samples were collected. The summary data FOR these samples are b) What were the values obtained by the group for Cp and for Cpk the initial capability study? Comment on wour findings and explain why further improvements were necessary. c) What are the Cp and Cpk after the improvements? Comment on your findings, indicating why the group decided to change the centering of the process. d) What are the Cp and Cpk if the process were centered at 166 ? Comment on your findines. Chapter 3. Problems, \#31 - work only parts b) through d); the mean and the standard deviation for the data in Table 3.7 are 1627 grams and 2.83 grams respectively. The data in Table 3.7 represents the results from the initial capability study. Brothers, Inc. is conducting a study to assess the capability of its 150 -gram bar soap production line. A critical quality measure is the weight of the soap bars after stamping. The lower and upper specification limits are 162 and 170 grams, respectively. As a part of an initial capability study, 25 samples of size 5 were collected by the quality assurance group and the observations in Table 3.7 were recorded. After analyzing the data by using statistical control charts, the quality assurance group calculated the Cp. process capability ratio, and the Cpk, process capability index, It then decided to improve the stamping process, especially the feeder mechanism. After making all the changes that were deemed necessary, 18 additional samples were collected. The summary data FOR these samples are: b) What were the values obtained by the group for Cp and for Cpk the initial capability study? Comment. on your findings and explain why further improvements were necessary c). What are the Cp and Cpk after the improvements? Comment on your findings, indicating why the group decided to change the centering of the process d) What are the Cp and Cpk if the process were centered at 166 ? Comment on your findings

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts