Question: Help with Rensan Case Study RENSAN CASE STUDY: PRINTING VECTRA Debra James had recently been given the responsibility to manage the marketing print category at

Help with Rensan Case Study

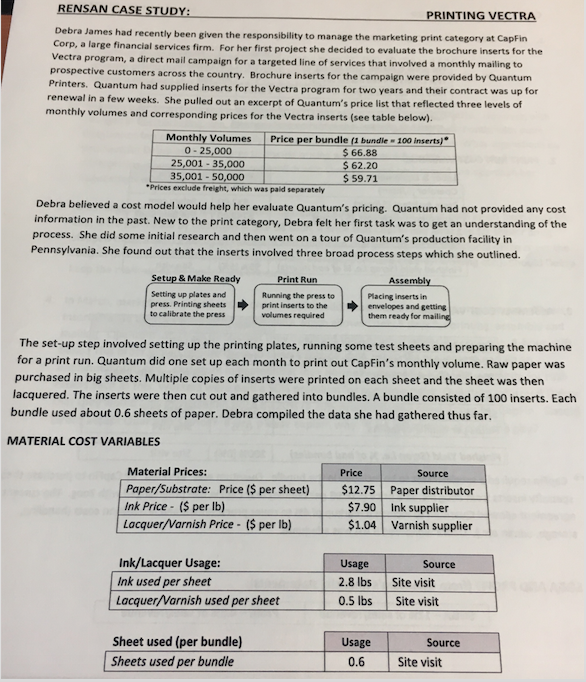

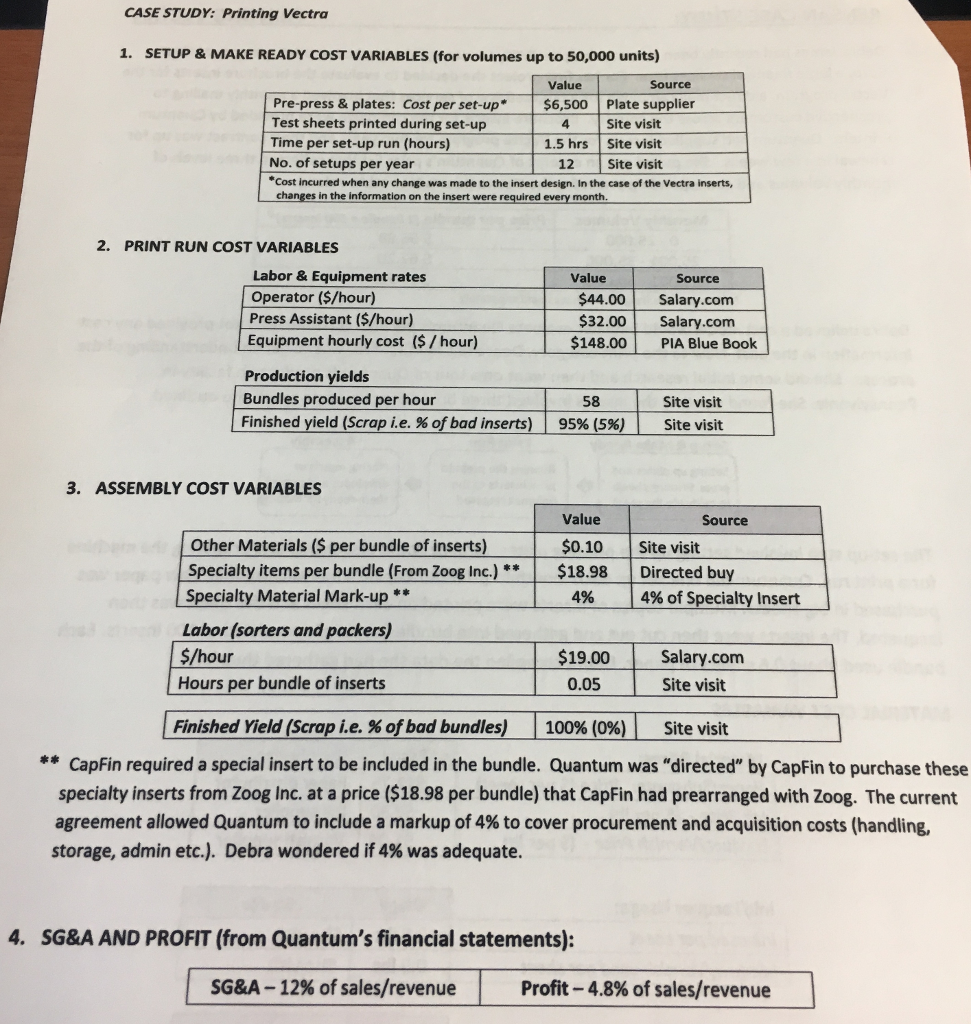

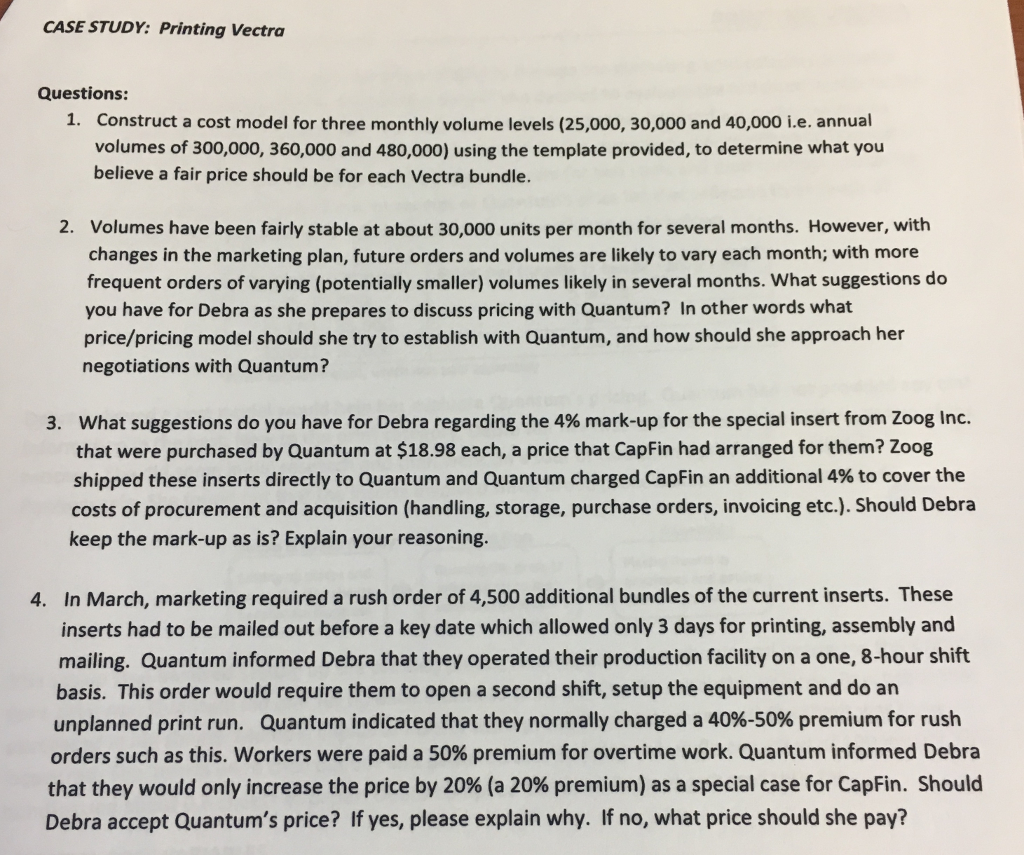

RENSAN CASE STUDY: PRINTING VECTRA Debra James had recently been given the responsibility to manage the marketing print category at CapFin Corp, a large financial services firm. For her first project she decided to evaluate the brochure Inserts for the Vectra program, a direct mail campaign for a targeted line of services that involved a monthly mailing to prospective customers across the country. Brochure inserts for the campaign were provided by Quantum Printers. Quantum had supplied inserts for the Vectra program for two years and their contract was up for renewal in a few weeks. She pulled out an excerpt of Quantum's price list that reflected three levels of monthly volumes and corresponding prices for the Vectra inserts (see table below). Monthly Volumes Price per bundle (1 bundle - 100 inserts) 0 - 25,000 $ 66.88 25,001 - 35,000 $ 62.20 35.001 - 50,000 *Prices exclude freight, which was paid separately Debra believed a cost model would help her evaluate Quantum's pricing. Quantum had not provided any cost information in the past. New to the print category, Debra felt her first task was to get an understanding of the process. She did some initial research and then went on a tour of Quantum's production facility in Pennsylvania. She found out that the inserts involved three broad process steps which she outlined. Setup & Make Ready Print Run Running the press to print inserts to the volumes required Assembly Placing Inserts in envelopes and getting them ready for mailing press Printing sheets to calibrate the press The set-up step involved setting up the printing plates, running some test sheets and preparing the machine for a print run. Quantum did one set up each month to print out CapFin's monthly volume. Raw paper was purchased in big sheets. Multiple copies of inserts were printed on each sheet and the sheet was then lacquered. The inserts were then cut out and gathered into bundles. A bundle consisted of 100 inserts. Each bundle used about 0.6 sheets of paper. Debra compiled the data she had gathered thus far. MATERIAL COST VARIABLES Material Prices: Paper/Substrate: Price ($ per sheet) Ink Price - ($ per lb) Lacquer/Varnish Price - ($ per lb) Price $12.75 $7.90 $1.04 Source Paper distributor Ink supplier Varnish supplier Ink/Lacquer Usage: Ink used per sheet Lacquer/Varnish used per sheet Usage 2.8 lbs 0.5 lbs Source Site visit Site visit Sheet used (per bundle) Sheets used per bundle Usage 0.6 Source Site visit RENSAN CASE STUDY: PRINTING VECTRA Debra James had recently been given the responsibility to manage the marketing print category at CapFin Corp, a large financial services firm. For her first project she decided to evaluate the brochure Inserts for the Vectra program, a direct mail campaign for a targeted line of services that involved a monthly mailing to prospective customers across the country. Brochure inserts for the campaign were provided by Quantum Printers. Quantum had supplied inserts for the Vectra program for two years and their contract was up for renewal in a few weeks. She pulled out an excerpt of Quantum's price list that reflected three levels of monthly volumes and corresponding prices for the Vectra inserts (see table below). Monthly Volumes Price per bundle (1 bundle - 100 inserts) 0 - 25,000 $ 66.88 25,001 - 35,000 $ 62.20 35.001 - 50,000 *Prices exclude freight, which was paid separately Debra believed a cost model would help her evaluate Quantum's pricing. Quantum had not provided any cost information in the past. New to the print category, Debra felt her first task was to get an understanding of the process. She did some initial research and then went on a tour of Quantum's production facility in Pennsylvania. She found out that the inserts involved three broad process steps which she outlined. Setup & Make Ready Print Run Running the press to print inserts to the volumes required Assembly Placing Inserts in envelopes and getting them ready for mailing press Printing sheets to calibrate the press The set-up step involved setting up the printing plates, running some test sheets and preparing the machine for a print run. Quantum did one set up each month to print out CapFin's monthly volume. Raw paper was purchased in big sheets. Multiple copies of inserts were printed on each sheet and the sheet was then lacquered. The inserts were then cut out and gathered into bundles. A bundle consisted of 100 inserts. Each bundle used about 0.6 sheets of paper. Debra compiled the data she had gathered thus far. MATERIAL COST VARIABLES Material Prices: Paper/Substrate: Price ($ per sheet) Ink Price - ($ per lb) Lacquer/Varnish Price - ($ per lb) Price $12.75 $7.90 $1.04 Source Paper distributor Ink supplier Varnish supplier Ink/Lacquer Usage: Ink used per sheet Lacquer/Varnish used per sheet Usage 2.8 lbs 0.5 lbs Source Site visit Site visit Sheet used (per bundle) Sheets used per bundle Usage 0.6 Source Site visit

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts